Ok guys, my tri-clamp fitting arrived today from StPat's. My idea was to pull it through from the inside, pop it out, then pull it through from the outside after the dimple was already formed.

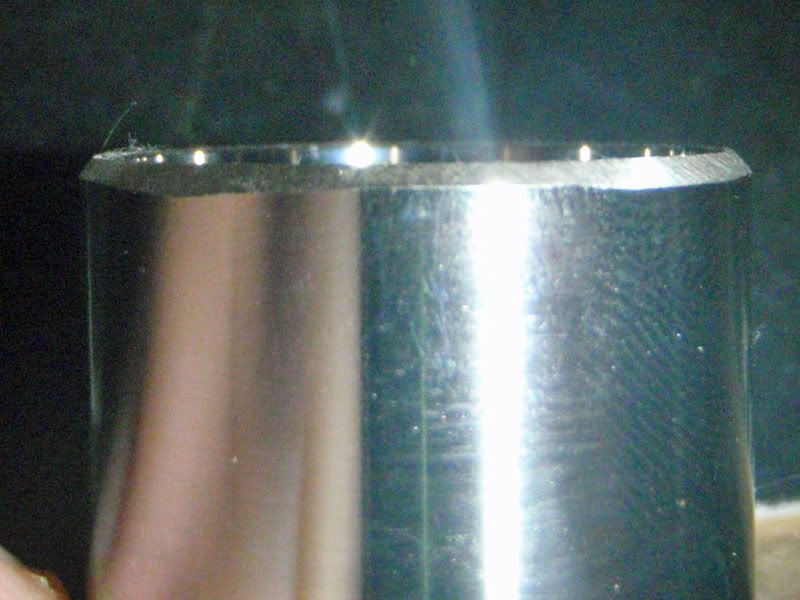

Step 1 was to ease the edges of the fitting. They're very sharp. A quick run on my 120 grit belt fixed that.

Step 2: pull the fitting through on the inside until it just exits the other side.

Be careful here, as the 1" tri-clamp is smaller than the 1/2" NPT coupling. I started with a 3/4" hole instead of 7/8". You also have to stop before pulling the stainless reducing coupler all the way through. A little at a time.

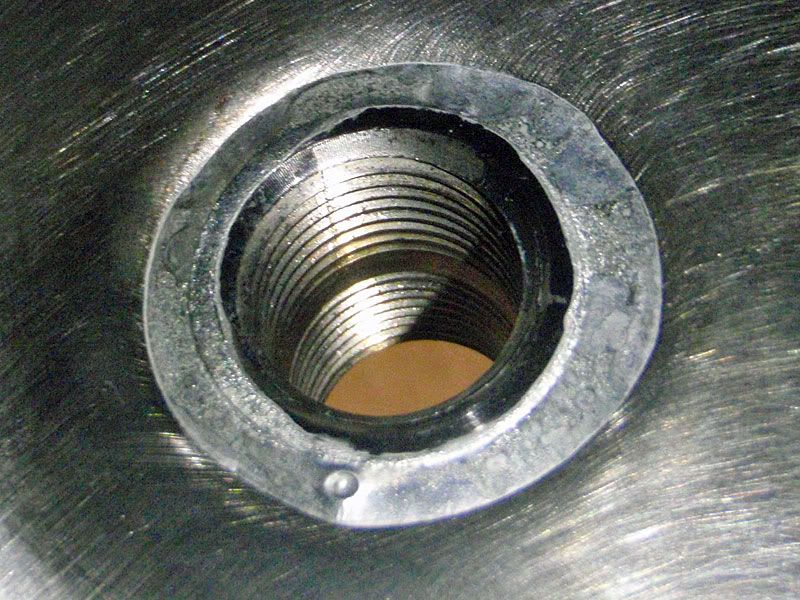

Step 3: remove the fitting. Hahahahahaha. When I said "tight fit" earlier, I was not kidding. I ended up putting a block of wood on the outside and beating it with a hammer to get it out - which, incidentally, worked a treat.

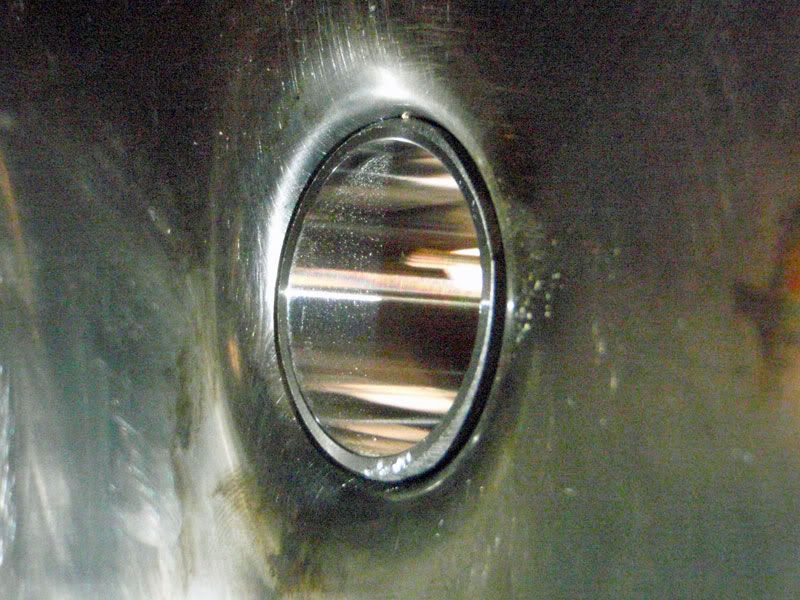

Step 4: push it back in from the outside. This is where easing the edges came in. It slid right in and was still tight enough that I had to whack it with the aforementioned block of wood to get it out.

But does this look pro, or what?

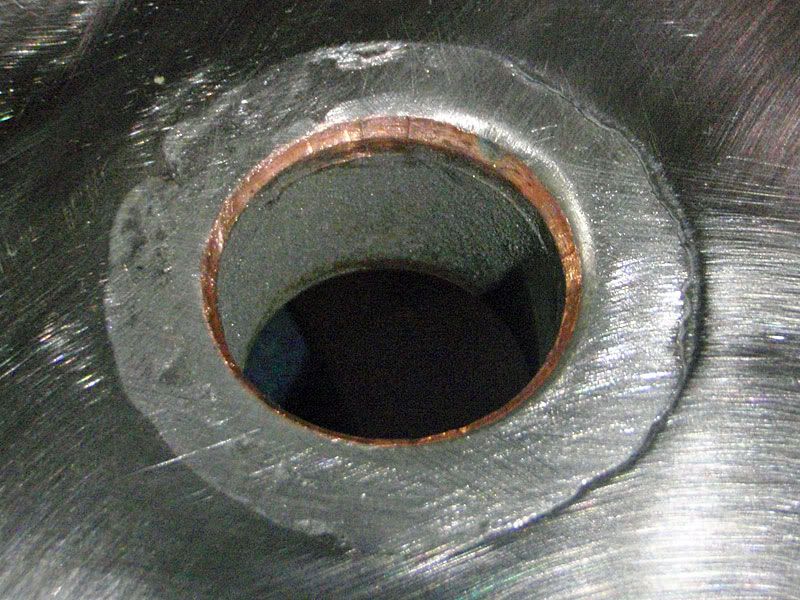

Also, for the person who asked, I tried making a dimple from the outside in. As expected, it was no problem at all.

I was thinking of putting this stuff in a separate thread, since it's not all about soldering. Could a mod weigh in on that? I don't want to make a mess of the boards.

-Joe

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)