ENOUGH TALK! Start trying some of this stuff and report back with the results!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Skipping traditional mashing?

- Thread starter odie

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

brewbama

Well-Known Member

- Joined

- Sep 20, 2013

- Messages

- 3,802

- Reaction score

- 2,829

If you choose to do this possibly step up your temps versus setting the controller at a high temp and move thru the temps gradually. Set your controller to something like 130*F for example. When it gets there, set it to 140*F. When it gets there set it to 150*F. Etc, etc. I believe you’ll not denature your various enzymes that operate at those temps as you move thru the temps because the controller won’t let the element fire above the set temp. If you set it at a high temp the element will continue to fire to reach that higher temp which could cause problems for your ‘lower temp’ enzymes. Savvy?

I don't really buy all this, you'll have xxx because of zzz enzymes if you start at yyy temp. I do believe it will change the nature of the beer. For the better or worse will largely depend on the tastes of the person drinking said beer.

What I see is that the beer will be very hard is not impossible to reproduce. That would not be a problem in my case since I have only brewed the same recipe (as close as possible) with the same ingredients in the same amounts once in my 8+ years of brewing.

Repeat-ability has not been a concern for me. There are too many styles to try. Even trying the same there are almost always changes I want to make to see if I can make a recipe either better, or different.

I say go for it. You can either heat part of the way for the start, or just dough in cold. You may get the best or you may get something terrible. Though I doubt the latter.

Try it and post the results...

What I see is that the beer will be very hard is not impossible to reproduce. That would not be a problem in my case since I have only brewed the same recipe (as close as possible) with the same ingredients in the same amounts once in my 8+ years of brewing.

Repeat-ability has not been a concern for me. There are too many styles to try. Even trying the same there are almost always changes I want to make to see if I can make a recipe either better, or different.

I say go for it. You can either heat part of the way for the start, or just dough in cold. You may get the best or you may get something terrible. Though I doubt the latter.

Try it and post the results...

odie

Well-Known Member

ENOUGH TALK! Start trying some of this stuff and report back with the results!

So it shall be done!

odie

Well-Known Member

I don’t have a temp controller. Element is on or off. I’m pretty sure it will be a gradual rise if I recirc constantly.

Separate but related question...enzymes denature at certain temps...but will they “renature” if the temperature is reduced? Or is it a permanent change?

Separate but related question...enzymes denature at certain temps...but will they “renature” if the temperature is reduced? Or is it a permanent change?

odie

Well-Known Member

This is so me....Repeat-ability has not been a concern for me. There are too many styles to try. Even trying the same there are almost always changes I want to make to see if I can make a recipe either better, or different.

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$1.91

$29.95

Mastering Homebrew: The Complete Guide to Brewing Delicious Beer (Beer Brewing Bible, Homebrewing Book)

Goodwill Retail Services, Inc.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

brewbama

Well-Known Member

- Joined

- Sep 20, 2013

- Messages

- 3,802

- Reaction score

- 2,829

I don’t have a temp controller. Element is on or off. I’m pretty sure it will be a gradual rise if I recirc constantly.

Separate but related question...enzymes denature at certain temps...but will they “renature” if the temperature is reduced? Or is it a permanent change?

Oh wow. A controller is a nice addition.

I don’t have a temp controller. Element is on or off. I’m pretty sure it will be a gradual rise if I recirc constantly.

Separate but related question...enzymes denature at certain temps...but will they “renature” if the temperature is reduced? Or is it a permanent change?

Permanent denature

Repeat-ability has not been a concern for me. There are too many styles to try. Even trying the same there are almost always changes I want to make to see if I can make a recipe either better, or different.

This is so me....

I've always wondered about this. For me, I can't judge my abilities as a brewer unless I can show that my process allows repeatability. Process is everything in brewing--without good process, the greatest recipe in the world will be crap. (And FWIW, process can't save a bad recipe, but most of the recipes we see today are decent ones).

Suppose you brew a tremendous beer (I've done that, btw, several times, and not just my view, the view of others who can tell). People want to buy my beer, a local bar owner wants to sell it. Why on earth would you not want to brew it again?

I can't figure out any reason except that the brewer is afraid to test his/her brewing skills, and by changing something, anything, it relieves them of the potential psychological damage of knowing they can't do it. And thus, they're not a very good brewer. Always brewing something new strikes me as being afraid to try it again--and not being able to achieve it.

If always having something new is the goal of brewing, why not just buy something new, and be done with it?

My 2 cents, YMMV, offer void where prohibited, and take it for what it's worth.

brewbama

Well-Known Member

- Joined

- Sep 20, 2013

- Messages

- 3,802

- Reaction score

- 2,829

I brewed a series of the same grist bill this Summer. It really helped dial in my processes and system settings. I have complete confidence in my results from a planning prediction because of that series. Plus the beers were pretty darn tasty! [emoji23]

If the OP is going to try this technique I recommend a 4-5 brew series like that to compare results.

If the OP is going to try this technique I recommend a 4-5 brew series like that to compare results.

Enzymes do not suddenly denature at a specific temp. The way things work is that the enzymes are denaturing at all temps, but at lower temps they may take years to denature, so for all practical purposes they aren't denaturing. At some higher temp, it may take days for the enzymes to denature - still not an issue for mash times ~1 hr. At an even higher temp, it might take hours to denature, and at an even higher temp, it might take only minutes. When we get to denaturing only taking minutes, now we are in the temp range where denaturing can affect what's happening in the mash. Take the temp even higher, and the enzymes are gone in seconds.I don’t have a temp controller. Element is on or off. I’m pretty sure it will be a gradual rise if I recirc constantly.

Separate but related question...enzymes denature at certain temps...but will they “renature” if the temperature is reduced? Or is it a permanent change?

I have never seen an exact definition of "denaturing temp," but it should be along the lines of "at the denaturing temp, one half of the enzymes have been denatured in xx minutes" where xx is in the range of 5 to 30 minutes. So, if you arbitrarily picked a 10 minute threshold, and half the "Z" enzyme was gone in 10 minutes at 151°F, then 151°F would be the "denaturing temp" for enzyme "Z". Then for "Z", half might be denatured in 20 minutes at 145°F, or half denatured at 5 minutes at 155°F.

And, as noted previously, once denatured they cannot be reactivated by lowering the temp.

Brew on

odie

Well-Known Member

So I’m re-reading on beta and alpha...

Beta happens lower but only works the ends of molecules and the alpha works higher breaking them in half allowing beta to now work on 4 ends vs 2 ends...but is also denaturing at this point since it got into alpha temps? What helps beta also hurts it? That kinda sucks...lol

Beta happens lower but only works the ends of molecules and the alpha works higher breaking them in half allowing beta to now work on 4 ends vs 2 ends...but is also denaturing at this point since it got into alpha temps? What helps beta also hurts it? That kinda sucks...lol

I've always wondered about this. For me, I can't judge my abilities as a brewer unless I can show that my process allows repeatability. Process is everything in brewing--without good process, the greatest recipe in the world will be crap. (And FWIW, process can't save a bad recipe, but most of the recipes we see today are decent ones).

Suppose you brew a tremendous beer (I've done that, btw, several times, and not just my view, the view of others who can tell). People want to buy my beer, a local bar owner wants to sell it. Why on earth would you not want to brew it again?

I can't figure out any reason except that the brewer is afraid to test his/her brewing skills, and by changing something, anything, it relieves them of the potential psychological damage of knowing they can't do it. And thus, they're not a very good brewer. Always brewing something new strikes me as being afraid to try it again--and not being able to achieve it.

If always having something new is the goal of brewing, why not just buy something new, and be done with it?

My 2 cents, YMMV, offer void where prohibited, and take it for what it's worth.

I've made the tremendous beer. I make another, different one, it is also tremendous. I have made a beer that I did again differently to try to improve, sometimes better, sometimes not. I have brewed the same beer with a change just to make it different.

I have made beers that people said "Why don't you sell this?" I have brewed beer that people said "Can I get some more?" I have made only 2 batches in 109 that I dumped. Both extreme. One stayed pea green. I did not even taste that one. A third was not so good. Very sweet. It was very high ABV and stayed very sweet, I used about 1/2 of it for cooking. Not to bad. How many bad beers have you made.

I am not afraid to test my skills. Repeat-ability is not something that I have felt a need to concentrate on. I am confident in my process and not so full of myself that if I did try to repeat a recipe and it didn't turn out that I would be "psychologically damaged". I wouldn't really care too much....

If I like over 90% of my beers, and would rate my beers better than or equal to mid priced commercial craft beers about 70-75% of the time, why do I need to repeat a recipe?

If a cook makes meals that are very good but never uses a recipe, thus cannot repeat a meal exactly, does that make them a bad cook?? I don't think so.

"If always having something new is the goal of brewing, why not just buy something new, and be done with it?"

1) Because I enjoy brewing my own beer.

2) Because 70-75% of the time I prefer my beers more than mid priced commercial craft beers.

Actually, beta only works on one end of a chain, and once it gets to a branch bond, it's done on that chain. Alpha cuts chains at random points, not necessarily in the middle. When an alpha cuts a chain, it creates one new chain end that beta can work on. Alpha works at beta temps, but it works faster at higher temps. Also, alpha will create very fermentable wort, given enough time. It's not as efficient at creating small sugars as is beta.So I’m re-reading on beta and alpha...

Beta happens lower but only works the ends of molecules and the alpha works higher breaking them in half allowing beta to now work on 4 ends vs 2 ends...but is also denaturing at this point since it got into alpha temps? What helps beta also hurts it? That kinda sucks...lol

The limiting factor is the gelatinization rate, which is much slower at lower temps. Unfortunately when you get to temps where gelatinization starts happening quickly enough to be useful in a mash, you are also in the temp range where beta amylase (and also limit dextrinase) denature at significant rates. Also, smaller starch granules tend to need higher temps to gelatinize quickly, and may not gelatinize in mash time frames until you are at temps where beta denatures very quickly. In a mash you are in a race to complete gelatinization before all the enzymes are denatured.

Brew on

- Joined

- Nov 26, 2013

- Messages

- 9,915

- Reaction score

- 24,067

"Also, smaller starch granules tend to need higher temps to gelatinize quickly"

This surprises me @doug293cz

This surprises me @doug293cz

- Joined

- Nov 26, 2013

- Messages

- 9,915

- Reaction score

- 24,067

well I'll be.

http://beerandwinejournal.com/starch-v/

"When starch granules are exposed to hot water, the amorphous regions (composed of mostly amylopectin) begin to swell first. As the starch molecules begin to dissolve and are “opened up,” water molecules progressively become associated with the hydroxyl groups (—OH) on the outside of the molecule. This swelling disrupts the layered structure of the granules.

Smaller granules — which typically have higher amylose levels and more protein on their exterior — gelatinize at slightly higher temperatures than the more amylopectin-rich large granules. (And remember, most of the weight of the starch comes from large granules.)

Older studies have shown different patterns of gelatinization (with regards to how quickly large and small granules dissolve) in different barley varieties."

http://beerandwinejournal.com/starch-v/

"When starch granules are exposed to hot water, the amorphous regions (composed of mostly amylopectin) begin to swell first. As the starch molecules begin to dissolve and are “opened up,” water molecules progressively become associated with the hydroxyl groups (—OH) on the outside of the molecule. This swelling disrupts the layered structure of the granules.

Smaller granules — which typically have higher amylose levels and more protein on their exterior — gelatinize at slightly higher temperatures than the more amylopectin-rich large granules. (And remember, most of the weight of the starch comes from large granules.)

Older studies have shown different patterns of gelatinization (with regards to how quickly large and small granules dissolve) in different barley varieties."

Beernik

Well-Known Member

The only plug I will give for ‘repeatability’ is you don’t want it necessarily because you want to make the same beer every time. You want it because repeatability = process control. If you have control and make a mediocre beer, it’s more likely to be because of the recipe, not a process mistake.

I would say, a good target would be to spend at least an hour going from 120F to 170F. That will probably give you a good mix of alpha & beta mash temps. If the time is less than an hour, it will skew to be more like an alpha mash.

I would say, a good target would be to spend at least an hour going from 120F to 170F. That will probably give you a good mix of alpha & beta mash temps. If the time is less than an hour, it will skew to be more like an alpha mash.

I would point out that "starch granules" and "grits" are not synonymous. Grits are the chunks of crushed grain, and the grits can be made up of many starch granules. The starch granules are the inherent structure of the starch within the endosperm of the grain kernels.well I'll be.

http://beerandwinejournal.com/starch-v/

"When starch granules are exposed to hot water, the amorphous regions (composed of mostly amylopectin) begin to swell first. As the starch molecules begin to dissolve and are “opened up,” water molecules progressively become associated with the hydroxyl groups (—OH) on the outside of the molecule. This swelling disrupts the layered structure of the granules.

Smaller granules — which typically have higher amylose levels and more protein on their exterior — gelatinize at slightly higher temperatures than the more amylopectin-rich large granules. (And remember, most of the weight of the starch comes from large granules.)

Older studies have shown different patterns of gelatinization (with regards to how quickly large and small granules dissolve) in different barley varieties."

Finer crush forms smaller grits, which exposes more surface area to the water so gelatinization can begin on the granules. In a larger grit, with multiple granules, the inner granules won't see much water (and can't gelatinize) until the surrounding granules are mostly gelatinized and dissolved away. This is why finer crushes gelatinize and convert faster than coarser crushes.

Brew on

- Joined

- Nov 26, 2013

- Messages

- 9,915

- Reaction score

- 24,067

Grits grains gruits black bears battlestar gallactica, oh my!

That now makes sense.

Thanks.

That now makes sense.

Thanks.

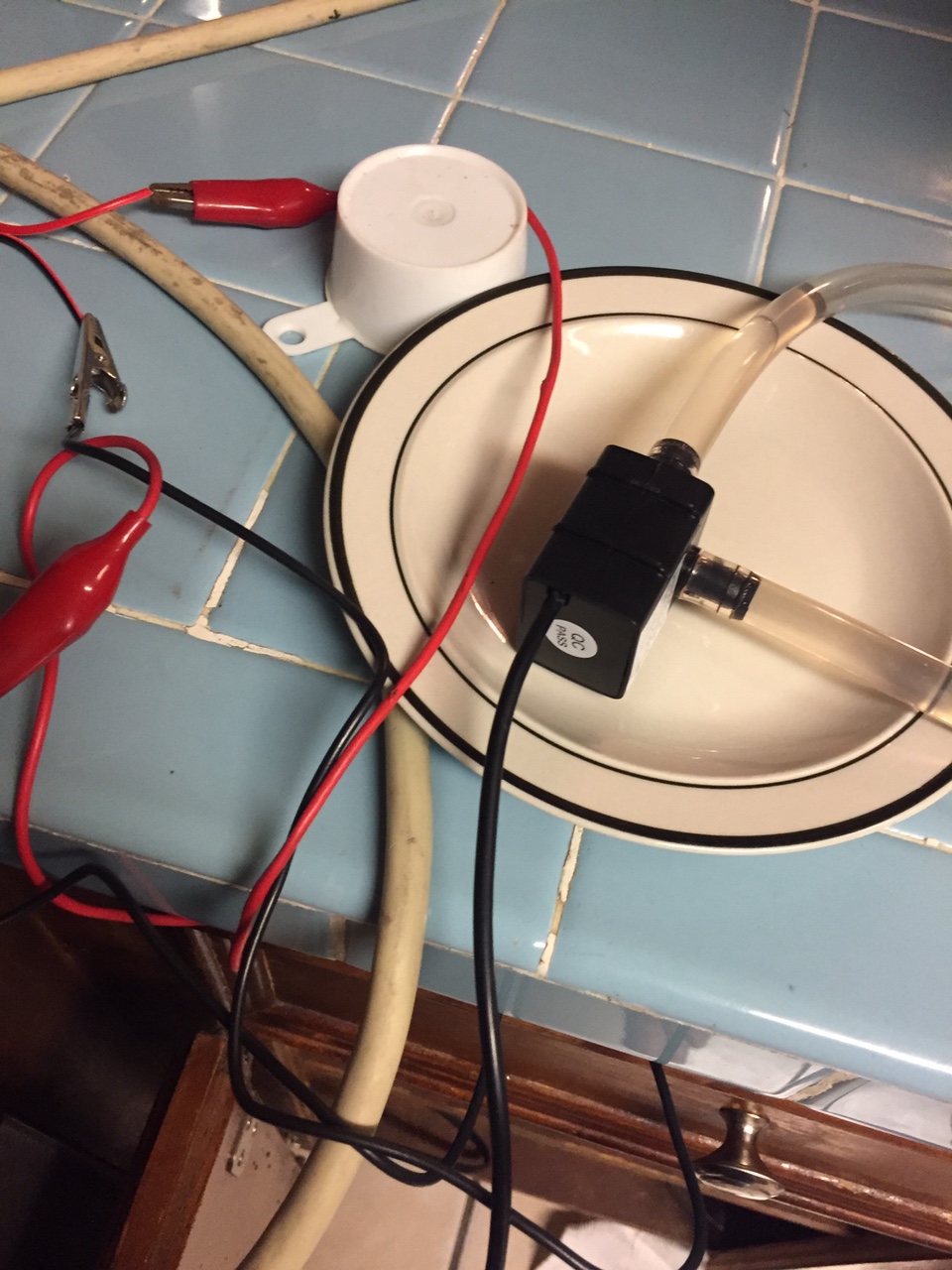

Is that pump rated "food safe" (ie. NSF), and will it be exposed to boiling wort (only rated to 100°C/212°F)?

Pump is rated for a max 1.15 gal/minute, lower if liquid has to rise in elevation.

Brew on

Pump is rated for a max 1.15 gal/minute, lower if liquid has to rise in elevation.

Brew on

Boiling takes care of microbial contamination, but may not eliminate chemicals leached from some types of plastic (depends on the vapor pressure of the specific contaminant at boil temp.)Only planning to mash with it. Food safe? Dude this is ebay...lol

It’s probably just fine but the wort gets boiled afterwards anyway

Brew on

Totally agree that you can mash and boil for less time. This is probably where I'd look for time savings.Another possibility: Just cut the mash short and/or the boil short if you want to save time. 60 minutes isn't necessary for either.

Statistically significant -- yes.

Practically significant -- maybe. Try it yourself and see if you detect a difference and whether you prefer it. A thousand experiments couldn't determine whether you as an individual can tell them apart or which way you prefer.

They provided OG and FG for both beers in the exbeeriment.

Cheers

brewbama

Well-Known Member

- Joined

- Sep 20, 2013

- Messages

- 3,802

- Reaction score

- 2,829

Being as this is a hobby, I’ll never understand why homebrewers want to reduce time getting to brew. My fermenter is empty at the moment and I am chomping at the bit for the chance to brew again. Why do I want to cut it short? Whatever floats your boat I guess. Cheers!

applescrap

Be the ball!

Yes, exactly, Marshall tested it at brulosophy. I dont think what we wanted came from it, but give it a go and let us know! Yep, got hammered for biab in the day too, so yeah, anything against the norm. I think you are cool, best of luck and hope to see what you find! In fairness, iirc, I got a lot of slack because I was asking others to test. I'm not scientific enough for any proper testing, just recently started taking gravity readings.Hammered like the first BIABers ??? People resist new ideas and change. I don’t think anyone has mentioned actually done it before...screw It I’m doin it next batch...lol

I guess what I’m really proposing is a continuously inclining mash??? Meaning no real steps (rise, pause,rise,pause) but a slow but steady incline of temps through the temp range of each traditional “step”. My kettle the element is not in direct contact with the mash and if I recirc constantly the mash should be evenly heated without any hot spots...I think

Last edited:

LittleRiver

Well-Known Member

- Joined

- Jul 3, 2017

- Messages

- 1,161

- Reaction score

- 1,375

Being as this is a hobby, I’ll never understand why homebrewers want to reduce time getting to brew...

I thoroughly enjoy my brew days, and look forward to them. I don't rush when I brew. But I don't want my brew days to unnecessarily take ALL day. I can enjoy a 3-4 hour brew session in the morning, then have the rest of the day to do something else. There is enjoyment to be had in an efficient process working just like you planned it.

- Joined

- May 28, 2018

- Messages

- 3,262

- Reaction score

- 2,971

...

applescrap

Be the ball!

This is a great question and I don't mind answering it. If I have answered it once I have answered it twice if not a dozen times. I understand that I am in the minority And that most see this as a hobby which is enjoyable and fun. Honestly talking about brewing and reading it is more of a hobby to me than brewing. I have been clear from day one that I don't like brewing. I do however like to drink homebrew and I also like the savings it affords me. To me brewing is a miserable chore that is a means to an end. I have always sought to brew quickly and inexpensively.Being as this is a hobby, I’ll never understand why homebrewers want to reduce time getting to brew. My fermenter is empty at the moment and I am chomping at the bit for the chance to brew again. Why do I want to cut it short? Whatever floats your boat I guess. Cheers!

To me brewing is no more of a hobby then cooking. Hobby or not I cook because I wanna feed my family, hobby or not I brew because I want to make beer cheaply and have a pipeline. I have minimal equipment that is both powerful and small in footprint. I guess that if I had a shed or some dedicated space that made the process easier and more enjoyable I could see enjoying it more. My other interests are splayed all over this forum. I have many interests and many things that I enjoy doing. I think I would also enjoy brewing more if I didn't brew so fast. Fast brewing sounds great but it is physical and a lot more fast paced. Conversely spending 6 hours to make beer sounds miserable. I golf and many see that as a complete and total waste of time. So I think you're right it's whatever floats your boat. Drinking beer I made floats my boat, making it not so much.

Wait .... I’ve not seen that before or overlooked it. You don’t like brewing? Whaaat?

brewbama

Well-Known Member

- Joined

- Sep 20, 2013

- Messages

- 3,802

- Reaction score

- 2,829

This is a great question and I don't mind answering it. If I have answered it once I have answered it twice if not a dozen times. I understand that I am in the minority And that most see this as a hobby which is enjoyable and fun. Honestly talking about brewing and reading it is more of a hobby to me than brewing. I have been clear from day one that I don't like brewing. I do however like to drink homebrew and I also like the savings it affords me. To me brewing is a miserable chore that is a means to an end. I have always sought to brew quickly and inexpensively.

To me brewing is no more of a hobby then cooking. Hobby or not I cook because I wanna feed my family, hobby or not I brew because I want to make beer cheaply and have a pipeline. I have minimal equipment that is both powerful and small in footprint. I guess that if I had a shed or some dedicated space that made the process easier and more enjoyable I could see enjoying it more. My other interests are splayed all over this forum. I have many interests and many things that I enjoy doing. I think I would also enjoy brewing more if I didn't brew so fast. Fast brewing sounds great but it is physical and a lot more fast paced. Conversely spending 6 hours to make beer sounds miserable. I golf and many see that as a complete and total waste of time. So I think you're right it's whatever floats your boat. Drinking beer I made floats my boat, making it not so much.

That is an interesting perspective.

I agree that I don’t want to spend all day slaving away in the brewery so efficient time management is needed. I do eliminate unnecessary activity, but I don’t want to cut the necessary steps short. I have streamlined my processes and assembled equipment that ensure an efficient day.

...but at 4-5 hrs every ~three weeks, homebrewing is something I personally look forward to, meticulously plan for, and have fun doing.

I enjoy brewday. It doesn’t produce stress, it relieves it. I get to brew. I don’t have to. I believe life is too short to choose to spend precious time doing something I dread.

Cheers to you my friend!

For me trying to compress the brew day into a couple of hours would make the process very stressful and less fun. I would rather it take longer, have some down time in the process to relax or do something else. I like the brewing as well as the beer.

But, I have too many projects going on right now so my brewing has been put on hold. Hopefully for not too much longer...

But, I have too many projects going on right now so my brewing has been put on hold. Hopefully for not too much longer...

applescrap

Be the ball!

Yeah, not really much at all. I like the way it smells and that's about it. If I had a brew buddy like you, I would enjoy it so much more I am sure. We could bust out 30 or 40 gallons in a day and that would be fun. Make a day of it, smoke some cigars make different styles, experiment. Also if I brewed slower, but on Wednesday night after work whipping out 10g in 3 hours. Not so enjoyable. More of a physical grind. Love chatting about brewing and reading oddly enough. I would rather be golfing on a Saturday. But after walking 18 holes in the sun, and grinding it out all day, getting home and brewing is a task not pleasure. I could brew on a different day I am sure, but have kids and family to consider. Need a new huge house with brew room man cave. Then I could brew all the time all set up and have less effort.Wait .... I’ve not seen that before or overlooked it. You don’t like brewing? Whaaat?

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

Oh wow. A controller is a nice addition.

Permanent denature

Had to reread that twice. Was thinking permanent denture as in implant. Scratching my head. LoL

So, yeah heat, then shut off.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

I'm kinda with you. It's like buy beer or do extract or pitch apple juice on some dregs. If you can do cider, pitching on the dregs of beer that used s-04 is pretty good. I've done it with WB-06 and it was like a green apple pucker.Being as this is a hobby, I’ll never understand why homebrewers want to reduce time getting to brew. My fermenter is empty at the moment and I am chomping at the bit for the chance to brew again. Why do I want to cut it short? Whatever floats your boat I guess. Cheers!

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

If you like to start early why not fill the kettle the night before and plug it into a timer plug to start an hour or so before you want to mash in? That way you wake up, grab a coffee and dough in straight away.

It's doesn't hurt to repeat this several times. LoL

Yeah, not really much at all. I like the way it smells and that's about it. If I had a brew buddy like you, I would enjoy it so much more I am sure. We could bust out 30 or 40 gallons in a day and that would be fun. Make a day of it, smoke some cigars make different styles, experiment. Also if I brewed slower, but on Wednesday night after work whipping out 10g in 3 hours. Not so enjoyable. More of a physical grind. Love chatting about brewing and reading oddly enough. I would rather be golfing on a Saturday. But after walking 18 holes in the sun, and grinding it out all day, getting home and brewing is a task not pleasure. I could brew on a different day I am sure, but have kids and family to consider. Need a new huge house with brew room man cave. Then I could brew all the time all set up and have less effort.

OK gotcha. Perhaps something like grainfather would be better for you. I'll admit I like the cheap beer that comes from the hobby and am pretty tired after a brew day...down right exhausted...but I'd not trade brewing for free beer delivered to the house.

applescrap

Be the ball!

Agreed. I enjoy drinking my own beer immensely. And others hb as well. Enough I am willing to make it. I make ciders now too. I like the gf. Ultimately it was so much cheaper and more powerful to make a rig. I use a 5500w element on a brew hardware stick dunked in a 15g pot with a small auber pid box. It all fits inside the kettle. I am just about 3 hours for 10g day with 45 min mash and boil. Lately no chilling so much faster. I paid 120 for element and stick iirc and 250 for auber parts pid box. So there you go. Plus 80 for kettle. So 450 for the system. At the time about half a gf price. I do want one or zymatic. I think my system is king for speed, size and value and have seen others emulate it. A lot of thought went into it. Since elements not mounted I can buy larger kettles and upgrade. Wish I would have got 25g the first time. I appreciate your comments and love that people love brewing. Wish I could share the joy. I like meeting people like you all and learning about new things! I have a wood fired pizza oven coming today and love making pizza with kids.OK gotcha. Perhaps something like grainfather would be better for you. I'll admit I like the cheap beer that comes from the hobby and am pretty tired after a brew day...down right exhausted...but I'd not trade brewing for free beer delivered to the house.

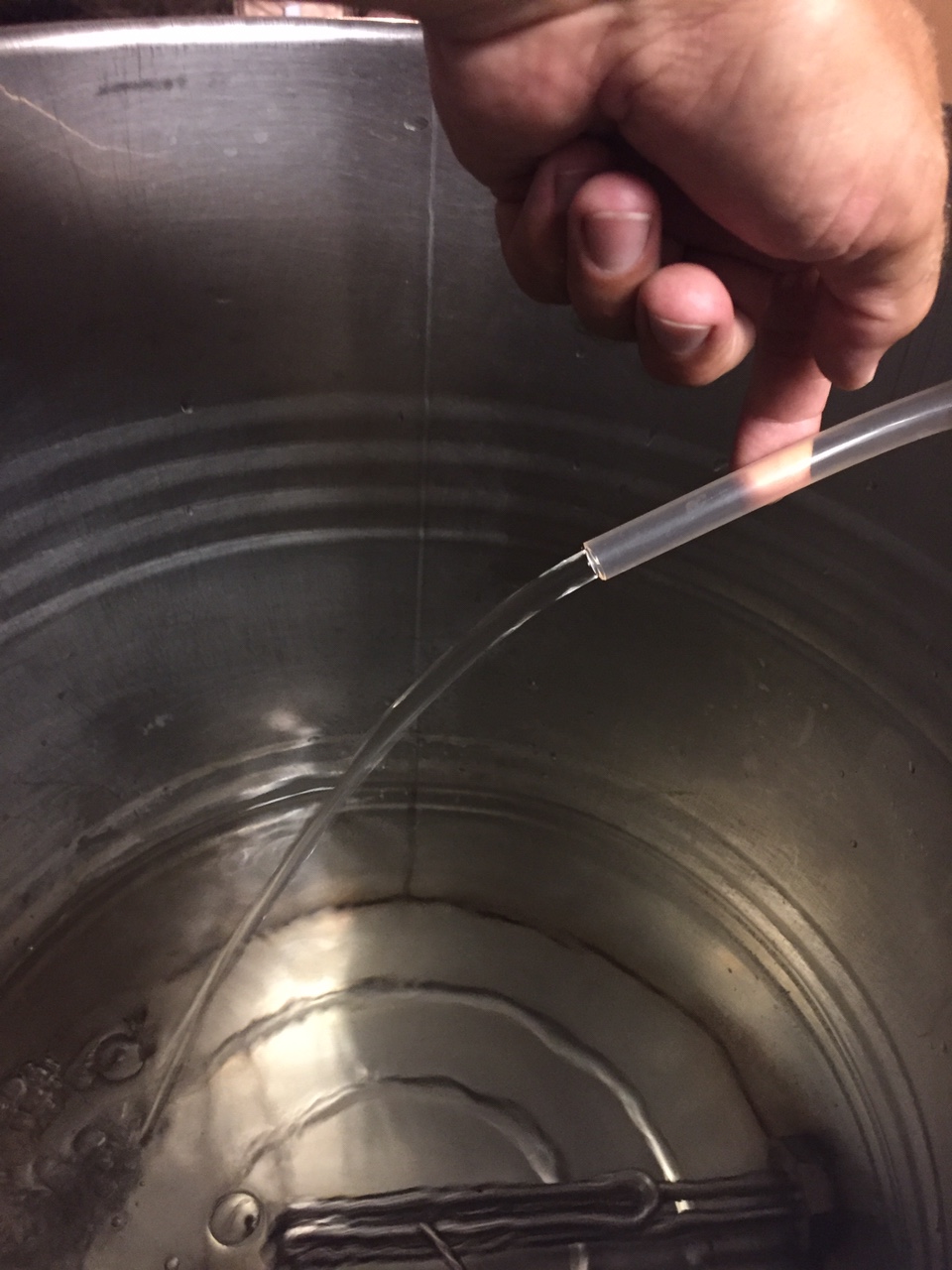

odie

Well-Known Member

Back from my trip. 9000 miles on a bike in 3 1/2 weeks. Anyway, had an old wall plug so hooked it up. Fills a pint in 7 sec so I guess that’s decent for a cheap eBay pump. Will be mashing in around 100-120 next time and let it recirc until mashout temp is reached and see how it goes

odie

Well-Known Member

Well from searching some other threads...it kinda sounds like if i mash in very low and raise temps to mash out over an hours time will result in a much different wort than if I just mash the entire hour at regular temperature? No matter what Is done to try to streamline the process, it will ultimately affect the product?

Similar threads

- Replies

- 73

- Views

- 3K

- Replies

- 11

- Views

- 816