sounddoc

Active Member

I've got the BrewPi set up now (I'm using dotps1's Arduino uno / Raspberry pi build) and I'm now hooked on microcontrollers. I'm going to go down this route unless there's a better option in designing a spunding valve that can be tied into the version of brewpi that I'm using (former web developer here).

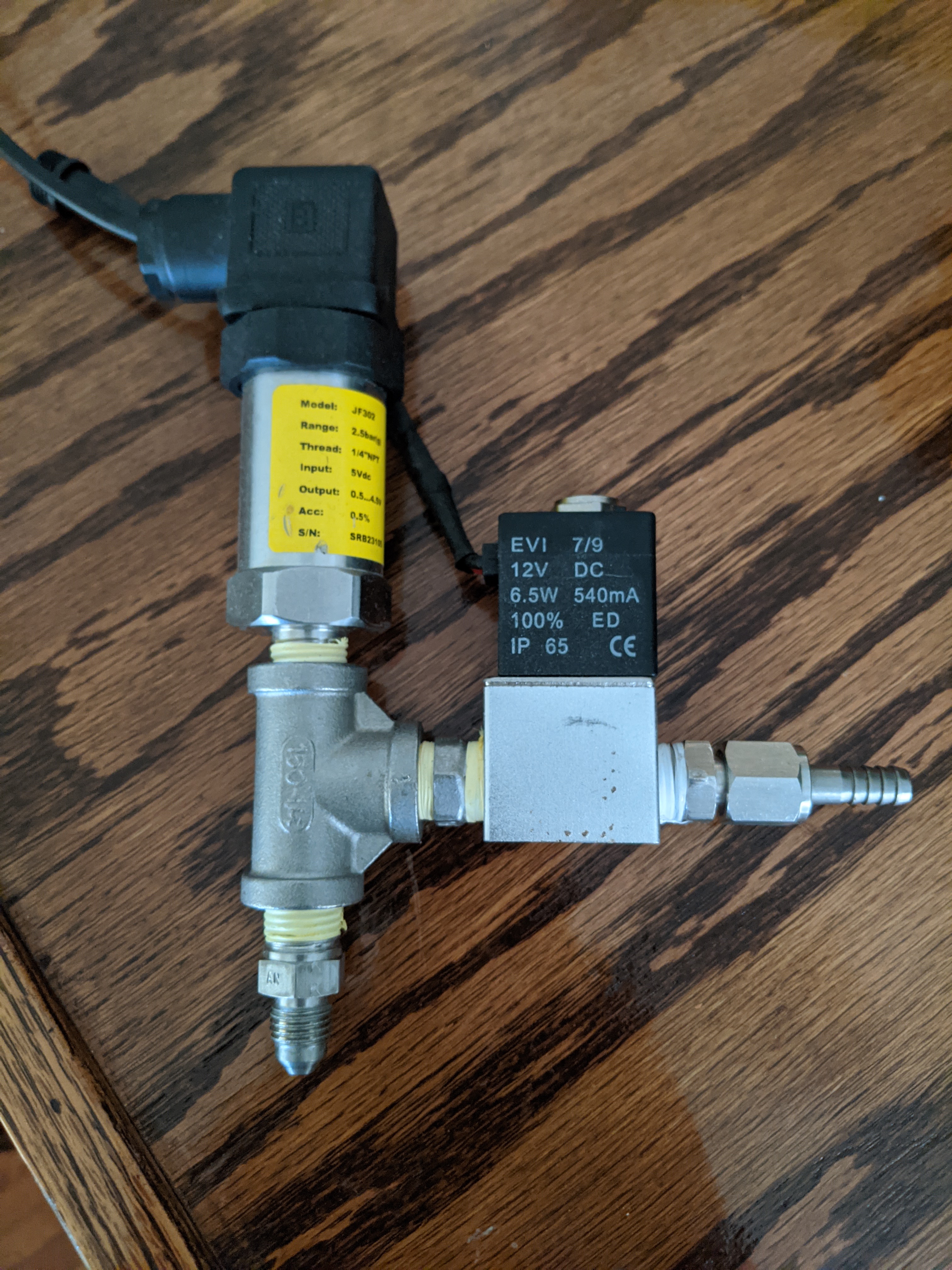

So far I have these two bits to start with:

https://www.adafruit.com/product/3965https://www.adafruit.com/product/4663

Obviously a 2nd Ardiuno will have to join the family (can't have too many, I'm finding).

Opinions? Other pieces of hardware (other than plumbing) that I'd need? It would be my first 'from scratch' Arduino project.

Thanks!

So far I have these two bits to start with:

https://www.adafruit.com/product/3965https://www.adafruit.com/product/4663

Obviously a 2nd Ardiuno will have to join the family (can't have too many, I'm finding).

Opinions? Other pieces of hardware (other than plumbing) that I'd need? It would be my first 'from scratch' Arduino project.

Thanks!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)