Charlie Little

Member

- Joined

- Dec 10, 2017

- Messages

- 6

- Reaction score

- 2

This DIY began back in mid September. I went looking for a way to make my own conical and this is the result. It's a very long story so unless y'all just absolutely want a play-by-play I will just hit the critical points.

I'm not a pro brewer or winemaker by any means. More of a fix-it and problem solver kind of guy with lots of tinkering experience in many subject categories. I read much about the DIY conical projects and saw a lot of pictures, some successes, failures and took metal note of all the likes and dislikes about the things.

I wanted it to be glass and food grade silicone in liquid contact, maybe some stainless steel fittings as required. I didn't want to drill holes in the bottom of the glass bottle for an airlock and I wanted sediment/lees to settle out in a flexible tube that could be externally clamped at some point prior to removal from the bottle.

This was the first prototype fixed to a 1.5 liter wine bottle, set in a wooden rack.

It was basically a two-hole silicone stopper in the bottom of a length of 1" ID food grade silicone tubing. A 3/8" ID piece of silicone tubing for the fill tube with valve for filling and a 1/4" OD silicone tube for the vent tube that goes up into an air gap at the "top" of the inverted bottle. I didn't figure it would handle primary fermentation so considered it as a secondary container to final fermentation apparatus. Here's the vent tube end floating up and out of the wine. After the racking from primary, it can stay in its bottle or carboy indefinitely and be 100% excluded from oxygen.

Thinking this might have merit someday as a product, I sent for a patent search that came back ok to proceed, so a provisional patent application was worked up and filed on 11/28/17. Doesn't mean I will get a patent within a year, just a form of protection while it's developed.

Most of the feedback to this stage, leans toward needing it to be bigger, to fit bigger bottles. I purchased a 1.3 gallon Italian Demijohn which has a 1-11/16" OD around the opening. The 1" ID tubing stretches to fit with much effort and I was not comfortable with the idea of it so set out to get larger tubing.

In the midst of all this, the thought of using different sized containers brought up many different sizes of wooden racks. I'm not really set up with proper tools or space to do this so opted for a simple hanging bottle harness, tied out of nylon rope to hang from a ceiling hook.

As you can see, it improved somewhat over the original prototype. Better tubing, exterior custom tubing clamp for the fill tube because I busted the first clip clamp I tried and a mini PET plastic wine bottle with vented lid for the bubbler. Stainless steel tubing connectors were used in the stopper.

One company I contacted which makes molded assemblies for the lab and pharmaceutical industries quoted me a price of $15,000. for a mold and $200. per unit. I said I was sorry for wasting their time and proceeded to figure out my own mold since I had made a few in years past for various things. How hard could it be? I really wanted it one-piece or at least a permanent fusion of pieces. I was also figuring out how difficult it is to acquire large diameter sizes of food grade silicone tubing in the US at reasonable prices but have found one. In the meantime I'm experimenting with a two part platinum cured, food grade silicone.

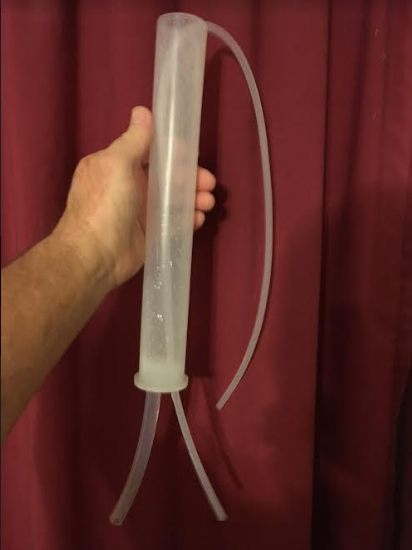

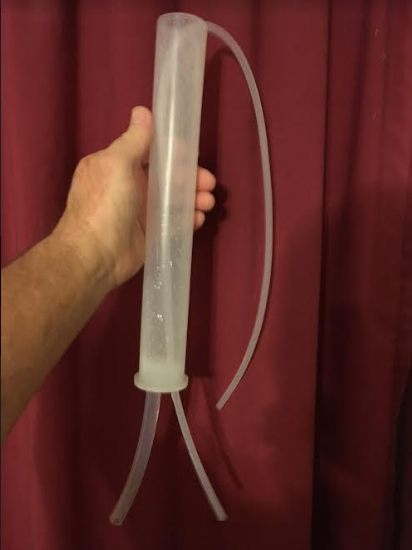

A couple or three molding attempts with various things finally resulted in the first platinum cured SiLeeSock with a 1-1/4" ID, fill and vent tube molded in. This was yesterday, 12/9/17 and it easily fits onto the 1.3 gallon Italian Demijohn.

I don't own a vacuum chamber for getting all the bubbles out of the platinum cured silicone so this latest version has many bubbles and appears to be more white than clear. I'll work on that. The next size mold will be to fit the larger Italian Demijohns with a 2" or larger opening. Some have said 2-3/4" diameter around the outside. I also have a plan to make a rolling cart, using the basket top in construction so the inverted 54 liter demijohns will have full support and even have a vent tube Sili Float that's coated with the platinum cured silicone so it will stay up and out of the wine regardless of liquid level. This was the float test before coating.

This is where we are now. Waiting to see if I get a Christmas bonus so I can order one of the big glass demijohns. The latest molded product is oven curing per manufacturer instructions for meeting FDA guidelines, then I'll rack a gallon of apple wine I've had working for several days into the 1.3 gallon and continue to tinker.

Thanks for looking.

I'm not a pro brewer or winemaker by any means. More of a fix-it and problem solver kind of guy with lots of tinkering experience in many subject categories. I read much about the DIY conical projects and saw a lot of pictures, some successes, failures and took metal note of all the likes and dislikes about the things.

I wanted it to be glass and food grade silicone in liquid contact, maybe some stainless steel fittings as required. I didn't want to drill holes in the bottom of the glass bottle for an airlock and I wanted sediment/lees to settle out in a flexible tube that could be externally clamped at some point prior to removal from the bottle.

This was the first prototype fixed to a 1.5 liter wine bottle, set in a wooden rack.

It was basically a two-hole silicone stopper in the bottom of a length of 1" ID food grade silicone tubing. A 3/8" ID piece of silicone tubing for the fill tube with valve for filling and a 1/4" OD silicone tube for the vent tube that goes up into an air gap at the "top" of the inverted bottle. I didn't figure it would handle primary fermentation so considered it as a secondary container to final fermentation apparatus. Here's the vent tube end floating up and out of the wine. After the racking from primary, it can stay in its bottle or carboy indefinitely and be 100% excluded from oxygen.

Thinking this might have merit someday as a product, I sent for a patent search that came back ok to proceed, so a provisional patent application was worked up and filed on 11/28/17. Doesn't mean I will get a patent within a year, just a form of protection while it's developed.

Most of the feedback to this stage, leans toward needing it to be bigger, to fit bigger bottles. I purchased a 1.3 gallon Italian Demijohn which has a 1-11/16" OD around the opening. The 1" ID tubing stretches to fit with much effort and I was not comfortable with the idea of it so set out to get larger tubing.

In the midst of all this, the thought of using different sized containers brought up many different sizes of wooden racks. I'm not really set up with proper tools or space to do this so opted for a simple hanging bottle harness, tied out of nylon rope to hang from a ceiling hook.

As you can see, it improved somewhat over the original prototype. Better tubing, exterior custom tubing clamp for the fill tube because I busted the first clip clamp I tried and a mini PET plastic wine bottle with vented lid for the bubbler. Stainless steel tubing connectors were used in the stopper.

One company I contacted which makes molded assemblies for the lab and pharmaceutical industries quoted me a price of $15,000. for a mold and $200. per unit. I said I was sorry for wasting their time and proceeded to figure out my own mold since I had made a few in years past for various things. How hard could it be? I really wanted it one-piece or at least a permanent fusion of pieces. I was also figuring out how difficult it is to acquire large diameter sizes of food grade silicone tubing in the US at reasonable prices but have found one. In the meantime I'm experimenting with a two part platinum cured, food grade silicone.

A couple or three molding attempts with various things finally resulted in the first platinum cured SiLeeSock with a 1-1/4" ID, fill and vent tube molded in. This was yesterday, 12/9/17 and it easily fits onto the 1.3 gallon Italian Demijohn.

I don't own a vacuum chamber for getting all the bubbles out of the platinum cured silicone so this latest version has many bubbles and appears to be more white than clear. I'll work on that. The next size mold will be to fit the larger Italian Demijohns with a 2" or larger opening. Some have said 2-3/4" diameter around the outside. I also have a plan to make a rolling cart, using the basket top in construction so the inverted 54 liter demijohns will have full support and even have a vent tube Sili Float that's coated with the platinum cured silicone so it will stay up and out of the wine regardless of liquid level. This was the float test before coating.

This is where we are now. Waiting to see if I get a Christmas bonus so I can order one of the big glass demijohns. The latest molded product is oven curing per manufacturer instructions for meeting FDA guidelines, then I'll rack a gallon of apple wine I've had working for several days into the 1.3 gallon and continue to tinker.

Thanks for looking.