Thanks, good to hear. So you basically just secure the probe by "clamping" the wire between the lid and kettle? I think I'm be investing in one of those. I like my pen style, but something to just rest on top makes a lot of sense to me to keep from opening the lid and potentially losing heat.

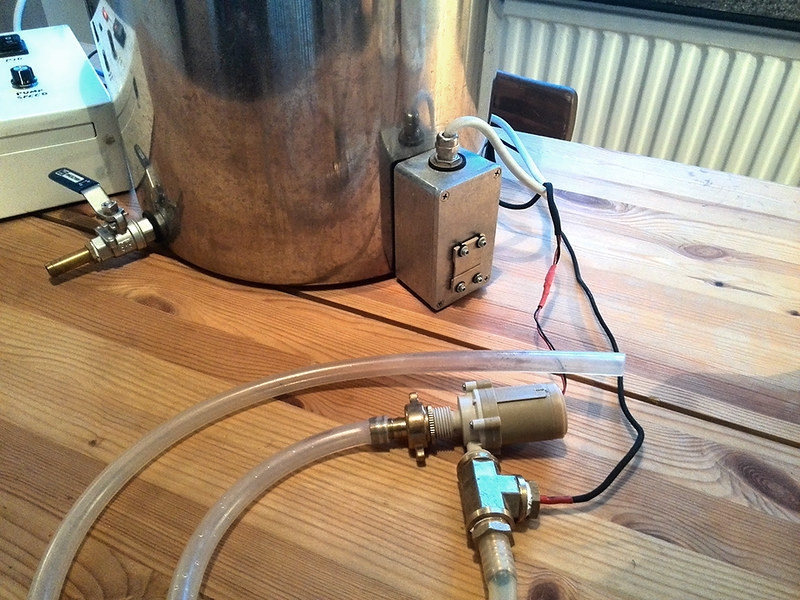

My thermometer

Polder Original Cooking All-In-One Timer/Thermometer

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)