copper2hopper

Well-Known Member

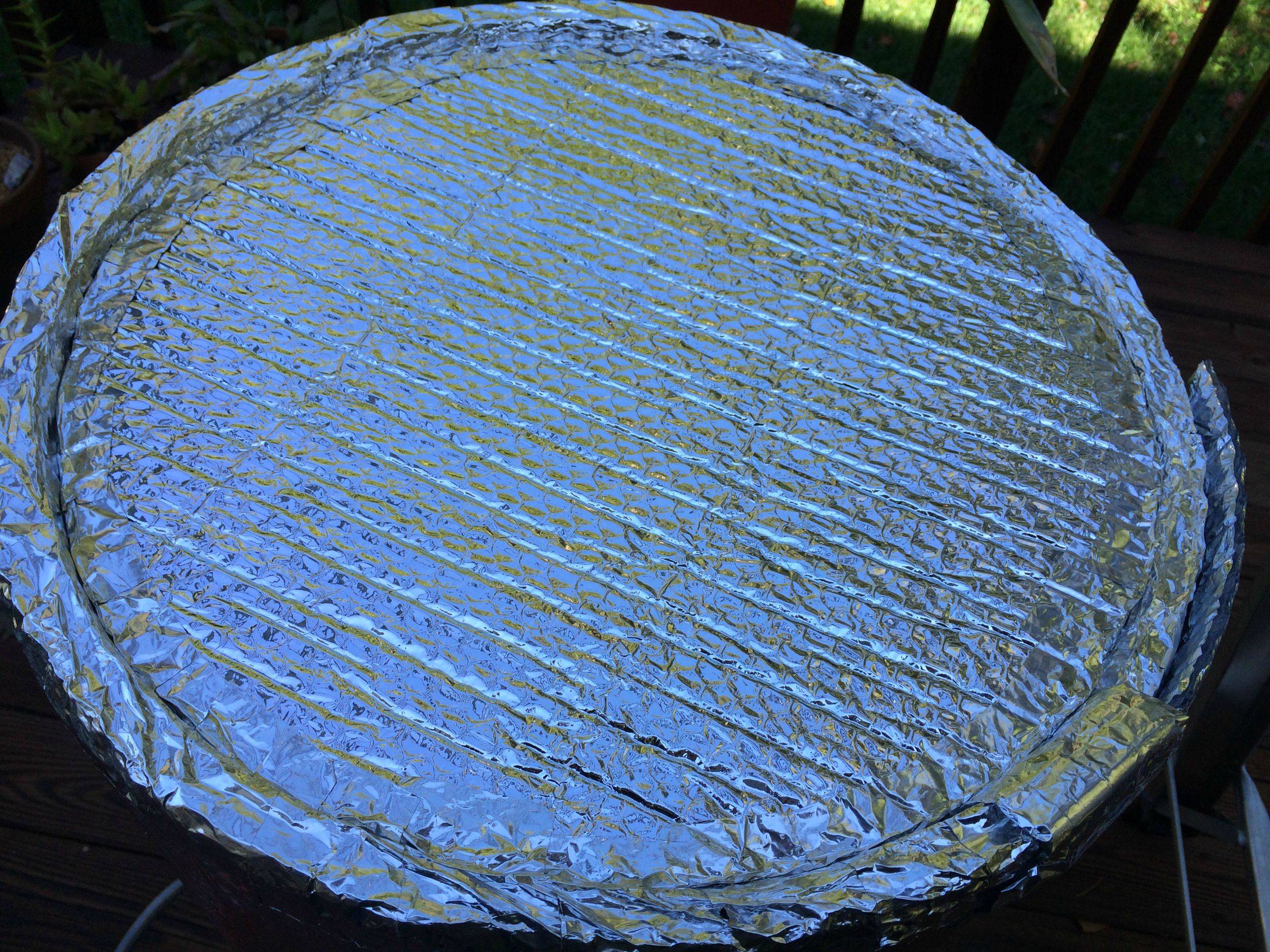

That insulation is called Reflectix.

Which is available at Home Depot. I just picked up my 2'x25' roll for $24 bucks to cover my keggle. Not bad

That insulation is called Reflectix.

What's your time to strike/boil with that setup?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Maintaining mash temps is terrible

Here's mine. I use the ladder for now while I figure out how to do a collapsible arm to raise the bag out of the kettle. It works just fine for now.

I still might use this table for the arm. I built the other one for brewing and storage.

What kind of controller do you have?

What kind of controller do you have?

The only controller I use is a STC-1000

Weird, the pic I linked was black z-28. And that's what it shows on my phone, I haven't looked on a pc

A shift in the matrix...

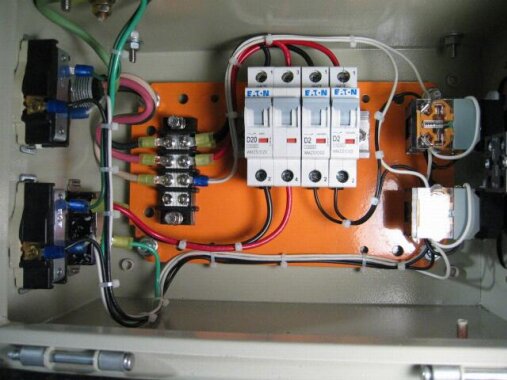

Here it is. Been running on this system for about 6 months.

View attachment 230361

View attachment 230363

View attachment 230364

View attachment 230365

Here it is. Been running on this system for about 6 months.

View attachment 230361

View attachment 230363

View attachment 230364

View attachment 230365

I like your style Daddymem; but, you lose points for plowing your driveway before brewing.

Here it is. Been running on this system for about 6 months.

View attachment 230361

View attachment 230363

View attachment 230364

View attachment 230365

I'm enamored with the efficiency of your set up. Could you describe your process? Looks like your chiller is mounted to the table and your hose connections are short hoses and quick-disconnects?

And the grain bag

View attachment 232183

Got any more info on the vent build? Looks good.

Thanks for the compliment. My pump and chiller are mounted to the underside of my brew table. I use camlocks for all of the hose connections

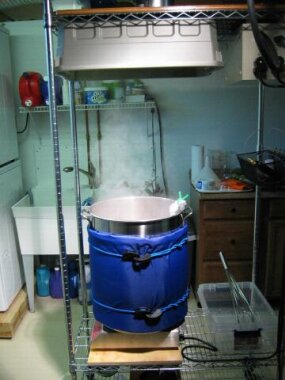

Here my mash with recirc

View attachment 232179

Here's the chill setup

View attachment 232180

Pump

View attachment 232182

And the grain bag

View attachment 232183

I really like the idea of the dome/hood, and I saw the same thread you did about the pilot system at UC Davis using a dome/hood on their boil kettle (theirs appears t be a copper "Braumister" hood). I have plans to do the same thing you have...I currently have a propane fired system (changing to BIAB next week with some new equipment), but I am going to buy a cheap stainless mixing bowl and cut vents in the top. I hope that it may show some efficiency in propane usage until I can get my electrical system going...