Hey Todd,

Yeah, the 3-way 'T-valve' gives my head a spin too... until you start to play with one .. then it makes more sense.

This description at Brewershardwared.com helps clarify the options.

The photo I uploaded shows the hoses without the manifold, and in a straight through setup. Good for pushing cleaner solution from HLT (right), into the MT (middle), then into the BK (left). However, on a brew day, I will recirculate my runnings on the MT before going into the BK, so that is a hose change. Same for the whirlpool on the BK at the end of the boil,

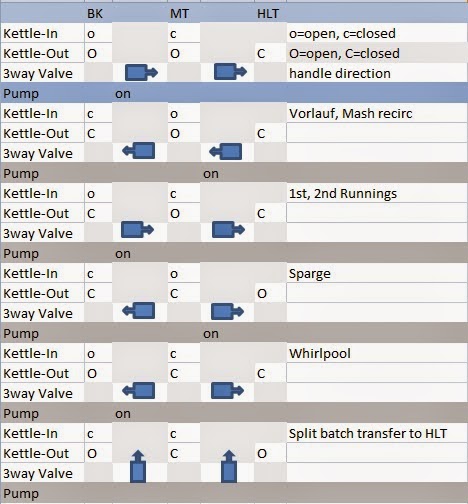

The PDF attached is a diagram of the manifold. When assembled, it fits on the ball valve port out on the bottom of the 3 kettles. The 2 3-way valves are in between each kettle, with a port going down to the pumps. Clamp on the manifold to the kettles, then the down ports to the pump inlets. The pump outlets go into the MT & BK as normal.

With this setup, I can change the flow to handle recirc on either MT or BK, or even move wort from the BK back into the empty HLT if I am doing a split batch. My only hose change at the moment should be when I finish whirlpol and want to go into the fermenter, and that is an easy one.

--LexusChris

View attachment manifold.pdf

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)