You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your panel

- Thread starter Jps101

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Excellent job Sam! You should be very proud of yourself!

John

John

docbliss

New Member

Very nice! Is that a cpu heatsink?

Very nice! Is that a cpu heatsink?

Yes, had an old AMD computer die so I repurposed the CPU heat sink. It has a powerful fan that keeps the SSR nice and cool.

Islandboy85

Well-Known Member

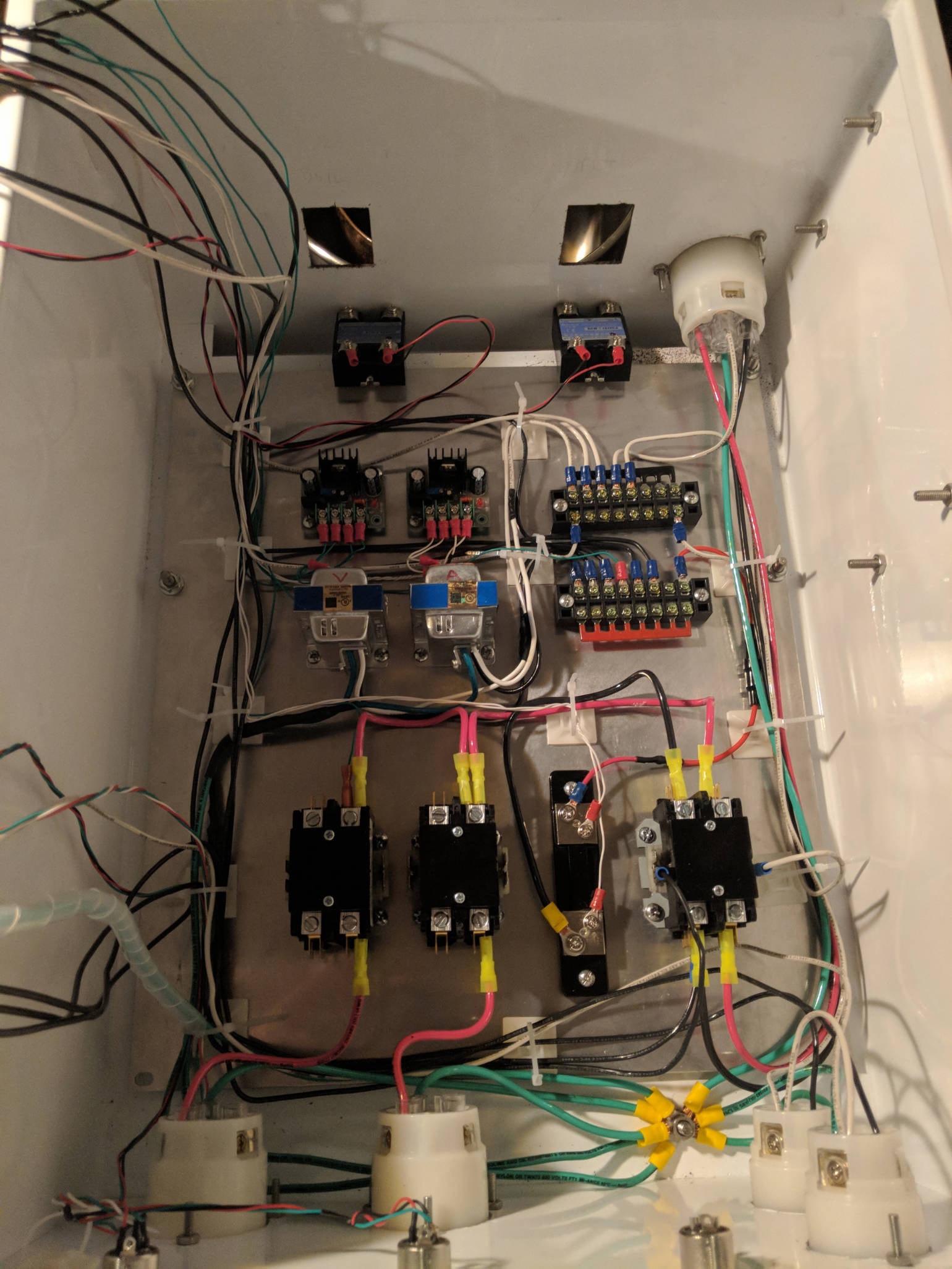

View attachment IMG_4871.jpg needs legend plates made up, and wiring, but here it is.

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

BellaRae

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

SoCal-Doug

Well-Known Member

Brew on!

augiedoggy

Well-Known Member

Brew on!

Converting from gas to electric? or just the redundancy of having both? looks like your set for up for dual elements too...

SoCal-Doug

Well-Known Member

Converting from gas to electric? or just the redundancy of having both? looks like your set for up for dual elements too...

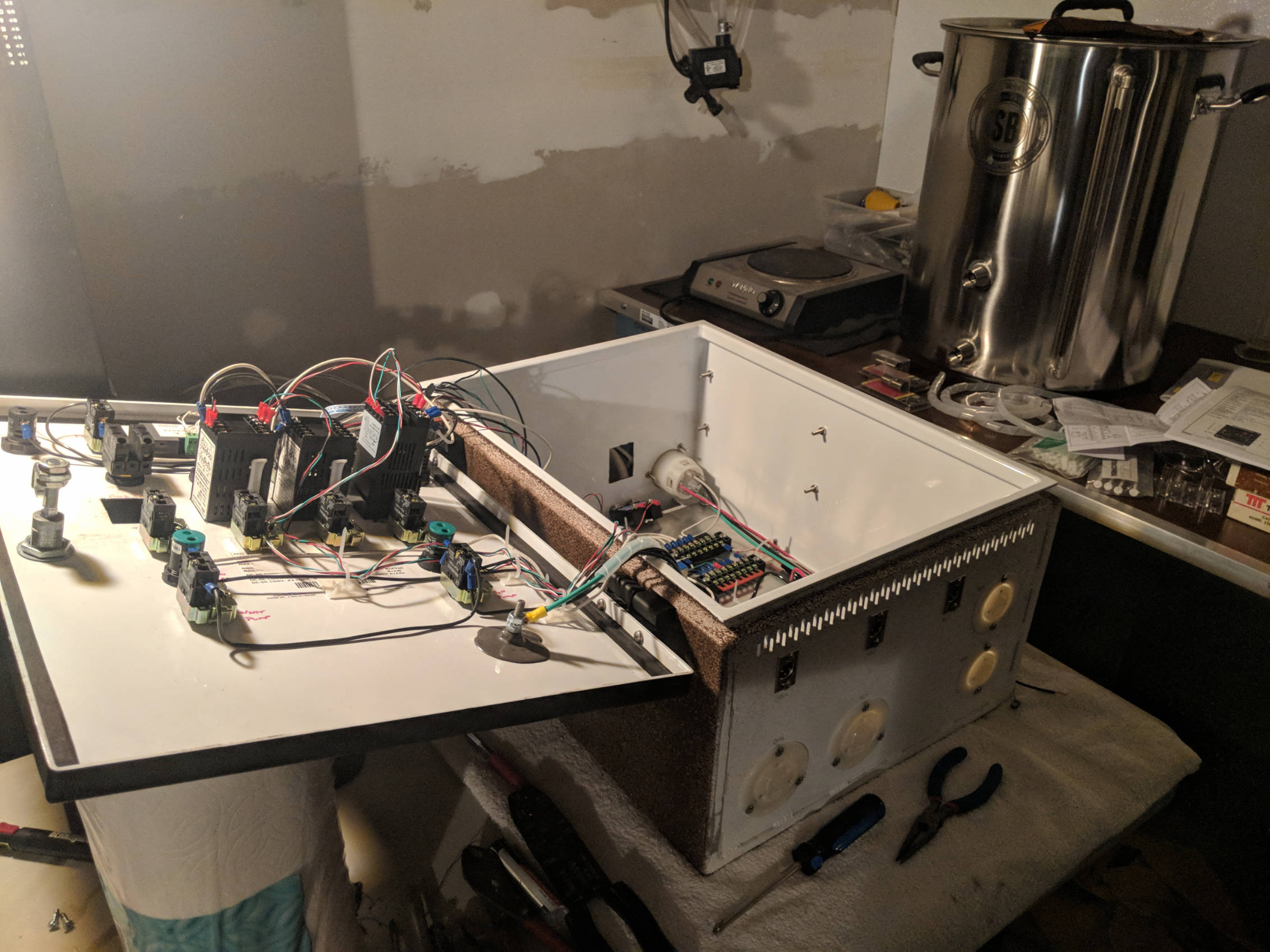

3rd rig build and it was my first dive into electric. I was insecure about completely giving up on gas

The other thoughts were... (1) Stay at 30A. Sometimes we will do multiple batches during a brew day. Boil one on gas while mashing the next batch on electric. (2) Until I saw it for myself, I was insecure about rise times on step mashing on electric only. (3) The option of powering it with 120V so if I bring the rig somewhere that doesn't have 240/30, Just use gas but still have temp displays and pumps. (4) Made the HLT element selectable for either the HLT sensor and PID, or the Mash/Wort sensor and pid. Tuned for both. Sure, I could just set the HLT PID about 2F above what I want to mash at, but conditions change. Let the Mash PID do it's job and be more than be a temp display. (5) Portable and self contained. Shove it all in a corner of the garage when not in use.

Funny thing is... I've never used the burners

Here's mine. All finished up, complete clone of Kal's system specs from the electric brewery website.

View attachment 1510083922805.jpg

View attachment 1510083922805.jpg

Similar threads

- Replies

- 3

- Views

- 827