cyberbackpacker

Well-Known Member

So, if you have a failure between your panel and the wall, the control panel will assume everything is ok, relying on the non-GFCI breakers in your house's panel to trip? Am I reading that correct? That seems a bit dangerous as regular breakers are NOT designed to protect human life, but save wires from burning.

I'd rather have my GFCI protection AT THE SOURCE of power. I have actually had a GFCI trip while brewing in a slight spill situation and I'm glad the power tripped at the wall.

You missed Devildog's other post... he has two 60a spa panels that are feeding the control panel; so he does have his GFI's in the proper orientation.

That said, Devildog, not to be a naysayer, but if you do eventually go "Pro" like you state, I really believe you are going to have to redo this panel if you want to use the mechanicals; mainly because having 2 feeds to your panel probably won't cut muster. Things might be different with your local codes, but I wouldn't bet on it.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

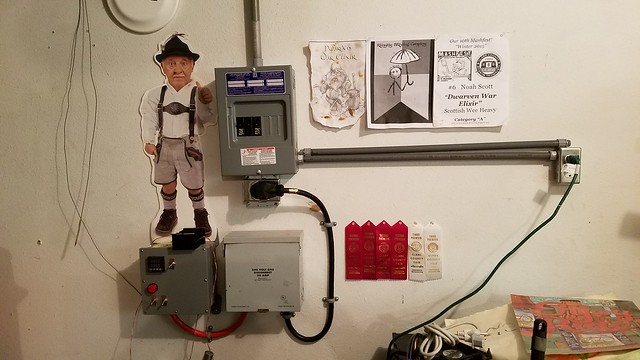

![20160226_170349[1].jpg 20160226_170349[1].jpg](https://cdn.homebrewtalk.com/data/attach/301/301852-20160226-170349-1-.jpg)

![20160430_124626[1].jpg 20160430_124626[1].jpg](https://cdn.homebrewtalk.com/data/attach/301/301853-20160430-124626-1-.jpg)

![20160504_133842[1].jpg 20160504_133842[1].jpg](https://cdn.homebrewtalk.com/data/attach/301/301854-20160504-133842-1-.jpg)

![20160504_133906[1].jpg 20160504_133906[1].jpg](https://cdn.homebrewtalk.com/data/attach/301/301855-20160504-133906-1-.jpg)

![20160504_133914[1].jpg 20160504_133914[1].jpg](https://cdn.homebrewtalk.com/data/attach/301/301856-20160504-133914-1-.jpg)