indianaroller

Well-Known Member

- Joined

- Apr 22, 2008

- Messages

- 196

- Reaction score

- 4

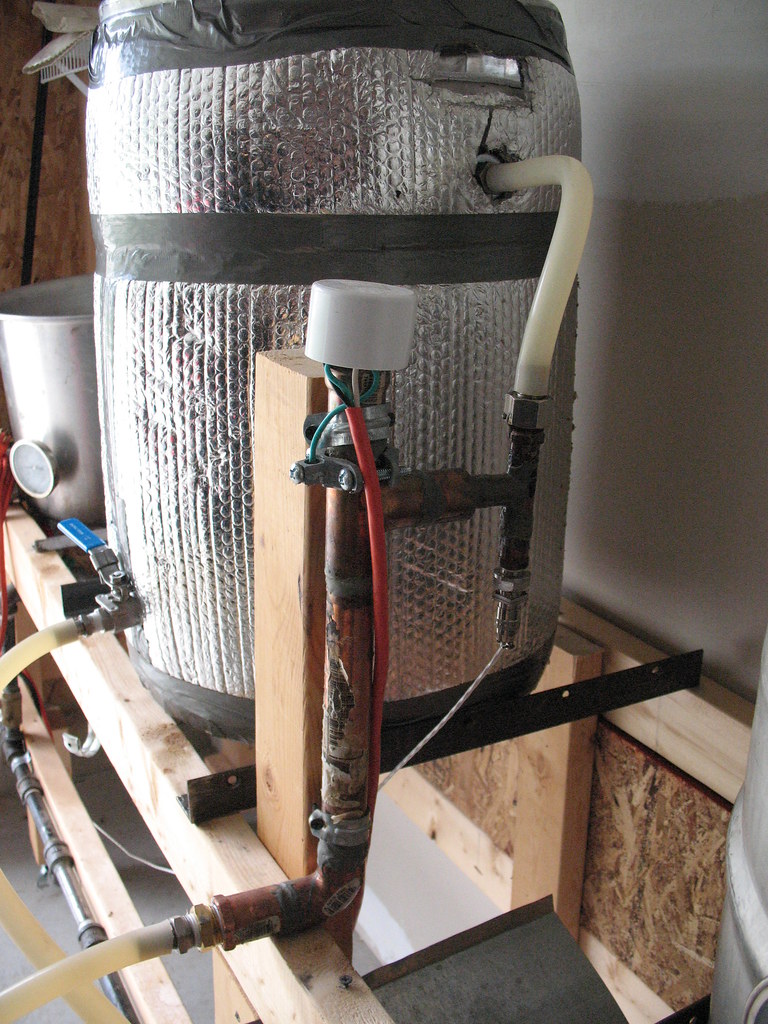

I am brewing with a single tier RIMS. My mash is controlled with a heating element and a PID and the pump recirculates constantly. My mash tun is a keg with a Northern Brewer false bottom.

Lately, I have been getting a lot of stuck mashes. This problem has been getting worse over the past 6 batches or so. My last batch got stuck within minutes of starting the recirulation. This is very weird because I never get mashes.

Today I filled my mash tun with hot water and turned the pump on. I watched the water flow out of the return pipe that sits on the top inside of the mash tun.

After monitoring a steady flow for several minutes I decided to switch the heater on. Within a minute the flow of water started to pulsate. The pulsating action of the water continued for about half a minute from when the heater was turned off.

Since I could not hear any difference in the pump noise I'm guessing the heat from my heater is causing the pulsating flow and for my mashes to get stuck.

Does anyone know what I should do? I am using a brand new heat stick beause last batch the heater chamber ran dry and the heater burnt up. I have tried plugging in my brewery to differnent circuits.

Lately, I have been getting a lot of stuck mashes. This problem has been getting worse over the past 6 batches or so. My last batch got stuck within minutes of starting the recirulation. This is very weird because I never get mashes.

Today I filled my mash tun with hot water and turned the pump on. I watched the water flow out of the return pipe that sits on the top inside of the mash tun.

After monitoring a steady flow for several minutes I decided to switch the heater on. Within a minute the flow of water started to pulsate. The pulsating action of the water continued for about half a minute from when the heater was turned off.

Since I could not hear any difference in the pump noise I'm guessing the heat from my heater is causing the pulsating flow and for my mashes to get stuck.

Does anyone know what I should do? I am using a brand new heat stick beause last batch the heater chamber ran dry and the heater burnt up. I have tried plugging in my brewery to differnent circuits.