Dump valve most likely.

Yes - dump valve. Makes cleaning a snap. It also traps small bits of malt.

Dump valve most likely.

Anyone have any experience with this?

http://www.amazon.com/dp/B00KUY388M/?tag=skimlinks_replacement-20

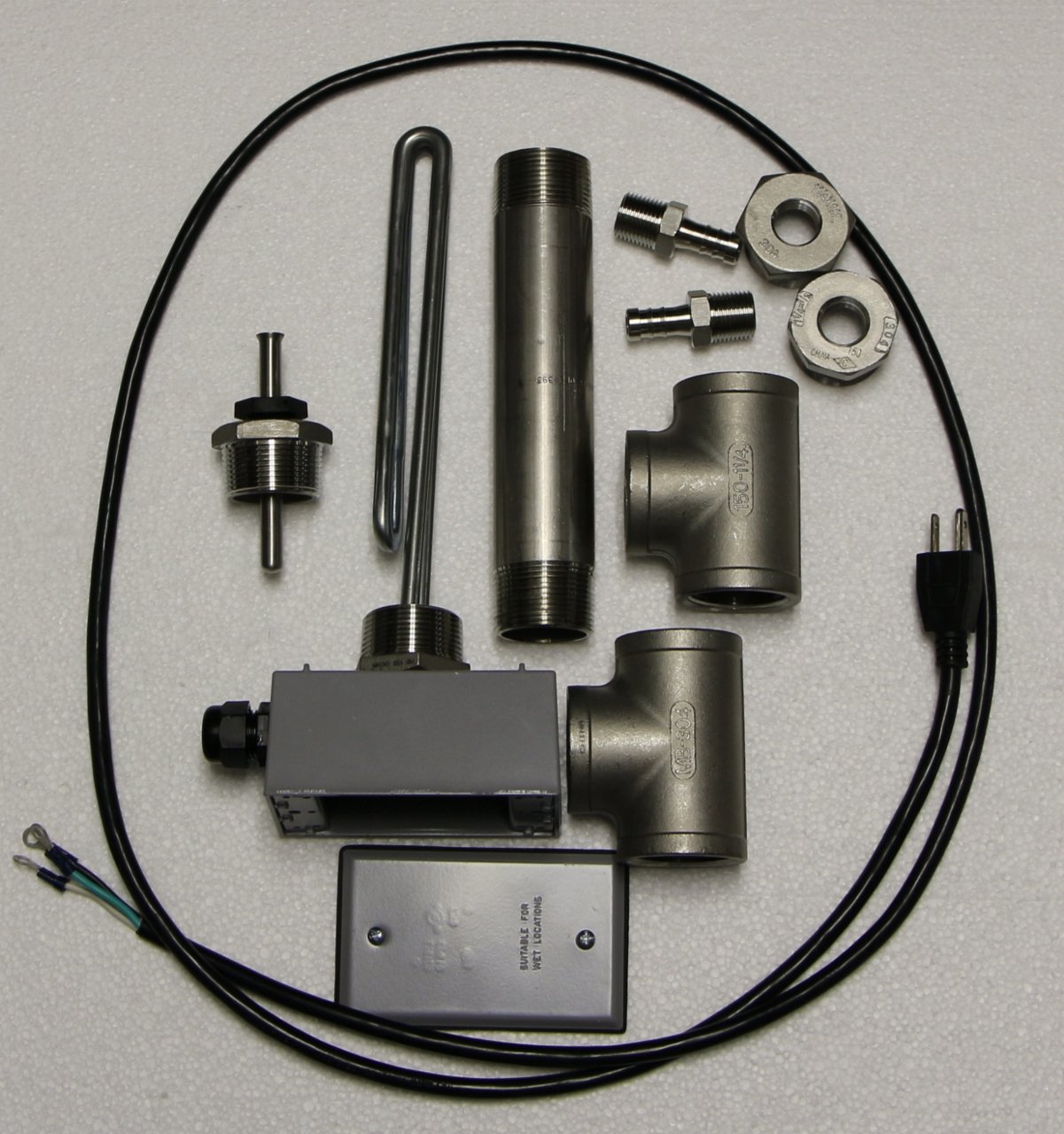

I actually purchased some of that stuff from that seller. I got his kit with the heater element pre- epoxied to the box and plug with the wiring rings already crimped on. I purchased all the SS pipe separately Which came out to roughly $45 from amazon. I am kicking myself as I should have talked to my plumber ( I am a general contractor) and had him get me the pipe, probably could have saved a few bucks, or had him get me all copper.

I did buy his pre built control box Which while a little pricy, works just right, came calibrated to the temp probe, and has a full set of instructions geared for our use.

I have used this system twice now, and changing from a recirculated NON heated mash to this setup was a %12 improvement in efficiency. A couple more tweaks and Ill be at 80%.

My setup, I still need to mount the tube, and its all modular since I don't have space to leave it all setup, it works really well. I have a copper soldered manifold on the bottom of the cooler, and a scatter plate mounted to the top. I am actually talking with one of my subs who just works with custom stainless steel to make a insulated stainless steel mash tun.

I read this entire thread, start to finish over a few weeks before doing this. It is so much fun. I'm now able to do two 5 gallon batches in one day (takes about 9 hours including all the cleaning). We just got a two burner (65000btu burners) propane mobile stand, so looking for a second 10gal pot to speed things up even more.

I actually purchased some of that stuff from that seller. I got his kit with the heater element pre- epoxied to the box and plug with the wiring rings already crimped on. I purchased all the SS pipe separately Which came out to roughly $45 from amazon. I am kicking myself as I should have talked to my plumber ( I am a general contractor) and had him get me the pipe, probably could have saved a few bucks, or had him get me all copper.

I did buy his pre built control box Which while a little pricy, works just right, came calibrated to the temp probe, and has a full set of instructions geared for our use.

I have used this system twice now, and changing from a recirculated NON heated mash to this setup was a %12 improvement in efficiency. A couple more tweaks and Ill be at 80%.

My setup, I still need to mount the tube, and its all modular since I don't have space to leave it all setup, it works really well. I have a copper soldered manifold on the bottom of the cooler, and a scatter plate mounted to the top. I am actually talking with one of my subs who just works with custom stainless steel to make a insulated stainless steel mash tun.

I read this entire thread, start to finish over a few weeks before doing this. It is so much fun. I'm now able to do two 5 gallon batches in one day (takes about 9 hours including all the cleaning). We just got a two burner (65000btu burners) propane mobile stand, so looking for a second 10gal pot to speed things up even more.

I'm now suspicious of any one who's first post on this forum is talking about this amazon seller's merch. Is that you Tom Hargrave?

Just an FYI for those who aren't aware: apparently that guy likes to come on here from time to time with fake accounts posing as a very satisfied customer.

Im not sure if I should be offended or not.

If you're Mr Hargrave then I care about as much for your feelings as you do for ethics.

If your not then welcome to the forum! I ment no offense toward you, and I apologize if you were offended. Seriously.

...but if you are... For shame!

I'm most certainly not Hargrave. I really don't understand both why you would think I was, and why this person is so terrible. Is he the brew-control seller on amazon?

If you do a quick search for his name on this forum you'll see why he is so concerned that a: you are him and b: that you bought a product of his.

Nice, it works well going back into the cooler? What do you use to disperse it when going back in?

Think your better off at that price point going with bobby's tri clamp rims (brewhardware.com) for $130ish and adding an element and wire.

This is what I am going to do once i have the money together. First I have to buy the pump.. Man this stuff is expensive.

**edit**

Question to those in the know...

Do you think there would be any difference in the useage of a copper pipe VS a stainless steel pipe? I was thinking that building it out of copper may be less expensive? Plus I could build it through items purchased at a home improvement shop, instead of having to order stuff online.

I just order one of these kits from Amazon: http://www.amazon.com/dp/B00KUY388M/?tag=skimlinks_replacement-20

After ordering I stumbled upon this thread, I wish I would have seen it earlier.

I didn't realize that the guy selling them was the same as the one here: https://www.homebrewtalk.com/showthread.php?t=120110

Even though I figured it would be more expensive I liked the idea of buying it as a kit because I don't really know a whole lot about hot water heater elements, and their size and figured if I tried to do it myself I would order the wrong size piping or fitting.

According to Amazon he has shipped it, I can update if/when I receive it if anyone cares.

In the mean time I was going to use the WS-1500ES Sous Vide Cooking Controller to power it: http://www.auberins.com/index.php?main_page=product_info&cPath=13&products_id=44

In the mean time I was going to use the WS-1500ES Sous Vide Cooking Controller to power it: http://www.auberins.com/index.php?main_page=product_info&cPath=13&products_id=44

Mine is a 5500w/220V element running at 120V/1375W. It's the ulta low density (has the folded back element) hot water element for high lime, which can be run dry. Works decent for 120V use. Use it to maintain mash temp once up to temp. and also during cleaning as shown below. With Mark's keg washer I run at or below 120F because of risk of scalding.

PlexVector...........I'm not wanting to do a "RIMS" setup, but I do want to make such a heater setup for a keg / carboy washer.

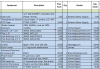

Without wading through 138 pages...........Is there a parts list for building said heater?

Thanks!

Anyone else having trouble finding all the the parts from Murray Equipment Co? I've typed in the URL and still cannot find anything. Advice?

Anyone else having trouble finding all the the parts from Murray Equipment Co? I've typed in the URL and still cannot find anything. Advice?

Sorry for the really, really, really late reply. You have to call them. The guy on the phone was great. when I started listing what I wanted he asked if I was a home brewer. That was well over a year ago.