ccostel

Well-Known Member

I have the rims tube connected directly to the Mash Tun return using a triclamp.

This is incorrect. A PID controller does not "dim" a power source as you described. A PID simply switches a power source on and off, just like an aquarium controller. However, the PID is "smart" in that it learns and adjusts its on and off cycling to more accurately control the difference between its setpoint temperature and its heated medium's temperature. It takes into account the present error in the proportional difference between those two values (P), the past error in the integral difference between those two values (I), and the future error in the differential difference between those two values (D). It is essentially a very sophisticated light switch, but it is by no means a dimmer.

You were correct when you talked about pulse-width modulation being a methodology for "dimming" a power source, but they are mutually exclusive things. This is not to say that they can't be used in conjunction with each other with a slightly more advanced circuit, but a simple PID controller will be more than adequate for keeping a heated medium (in this case wort) well within 1 degree of its setpoint.

I would say yes an aquarium controller could be used to control a RIMS, but the major drawbacks with that are the fact that aquarium controllers are meant for much smaller heater loads (typical aquarium heater mats are in the 10-100W range) and would need significant modification to control a typical RIMS load of 1500W or greater. Also, they are not as "smart" as a true PID controller and usually only use either PI, PD or sometimes only Proportional control and don't account for the entire PID spectrum of a system's temperature profile.

bazowie said:So go at the wiring from the diagram on this site but before you fire anything up have a electrician look at it. Wish you were in Oregon id hook you up

This is incorrect. A PID controller does not "dim" a power source as you described. A PID simply switches a power source on and off, just like an aquarium controller. However, the PID is "smart" in that it learns and adjusts its on and off cycling to more accurately control the difference between its setpoint temperature and its heated medium's temperature. It takes into account the present error in the proportional difference between those two values (P), the past error in the integral difference between those two values (I), and the future error in the differential difference between those two values (D). It is essentially a very sophisticated light switch, but it is by no means a dimmer.

You were correct when you talked about pulse-width modulation being a methodology for "dimming" a power source, but they are mutually exclusive things. This is not to say that they can't be used in conjunction with each other with a slightly more advanced circuit, but a simple PID controller will be more than adequate for keeping a heated medium (in this case wort) well within 1 degree of its setpoint.

I would say yes an aquarium controller could be used to control a RIMS, but the major drawbacks with that are the fact that aquarium controllers are meant for much smaller heater loads (typical aquarium heater mats are in the 10-100W range) and would need significant modification to control a typical RIMS load of 1500W or greater. Also, they are not as "smart" as a true PID controller and usually only use either PI, PD or sometimes only Proportional control and don't account for the entire PID spectrum of a system's temperature profile.

If it will fit, go to Home Depot and get the Camco 5500W 240V LWD (150W/in^2) Model 15597. Using this at 120V will give you 1375W and ULWD (12.5 W/in^2). This is the black folded back element. I use this in my RIMs and have run it at 120V in a water only test. It will maintain temp, but will be slow if you try to step mash.

If the fold back element is too wide (I bent mine to not touch the side walls of the tube), try Camco Model 15293 3800W 240V HD. Running at 120V this will give you 950W and LWD (37.5 W/in^2).

Basically look at the HD web site and look at 240V elements. Running at 120V you get 25% the power and 25% the power density. Target 50W/in^2 for the density to ensure you get LWD if you are worried about scorching.

I hope this helps...

What diameter pipe are you running with that 5500w element? I just ordered the electronics, now I have to order the pipe and fittings.

Thanks,

-G

I ordered 1.5in diameter stainless threaded pipe from Murray Equipment. It is a very similar setup to the early RIMs in this thread. As I mentioned above, I had to put an "S" bend the element so it would not touch the sidewalls. The "S" bend centers the fold back in the center of the tube instead of the long side of the fold back.

Thanks kwadric,

How long of a pipe nipple did you go with? I was looking into installing the element in aluminum cam locks for easy cleaning of the element. One other feature that I am debating is utilizing a union in the center of the rims tube to further disassemble the tube for cleaning. I was thinking about using a 6" and a 8" nipple.

My RIMs is similar to what you are talking about (except for the union). I used the 8in nipple. I measured from the tip of the element to the center of the tee with the wort exit port. It is over 4in. The element is 13.5 inches from the tip to the hex after the threads. If you decide to use a union, I think that you could go with two 3in pipes... an 8in and 6in plus the length of the union it will be very long (if I understood your plan correct).

Here are the parts that I used:

Murray Equipment - Stainless steel pipe

three 1.5in to 0.5in bushing

one 1.5 to 1.0in bushing

two 1.5in Tee

one 1.5in diameter by 8in threaded pipe

Pro-Flow Dynamics - aluminum camlocks

one 1.5in Type D Aluminum (with handles)

one 1.5in Type F Aluminum

two 0.5in Type F Aluminum

I assembled my RIMS by putting the 8in threaded pipe between the two Tees. I placed used a 1.5 to 0.5in reduction bushing in the top of each Tee and then a Type F Cam (w/o handles) for the wort in and out. At the end of one Tee, I placed a 1.5 to 0.5in reduction bushing and then used a compression fitting for a temperature probe. At the end of the other Tee, I used the 1.5in Type F Cam (w/o handles). I screwed the 1.0 in threaded heating element into the 1.0 to 1.5in reduction bushing. I screwed the other end of the 1.0 to 1.5in reduction bushing into the 1.5in Type D Cam (with handles to lock the cam).

I bought a PVC coupler that fit over the end of the heating element and used a two part epoxy to seal the electrical connections so that I could not short the heating element if I had any kind of leak. I use my RIMS tube horizontal. I have the two Tees offset by 90 degrees. I pump wort into the horizontal port (which is near the element) and out the vertical port (which is at the end with the temp probe).

Aschecte said:Ok I'm sure this has probably been asked a few times in this thread but, I can't read 1,000 + posts ...... believe me though I did try. My question is this on page one I fully understand the wiring diagram as I do have a rudimentary education in electrical wiring. I also do notice in that first diagram a few things missing such as switches ( optional ) and indicator lights. I'm pretty sure I understand how to wire in the inicators etc..... My real question is in a lot and I mean a lot of other RIMS posts online not necessarily on HBT I see people putting in extention bars for more terminals as well as dramatically different wiring and control selections. I understand there are many ways to skin a cat ( no offense to PETA ) but, is the OP's diagram only meant for a bare bones simple no frills RIMS or is there any other sources that fully show a schematic with those bells and whistles like indicator lights , manual overrides, safety fuses etc..... ? I want to use the OP's schematic as a jump off point but incorporate fuse protection for the element as well as including indicator light and isolation switches so I can run the pump alone to recirculate and "vorlauf" and then turn on the element and control to step and maintain the mash temps. THanks for any input.

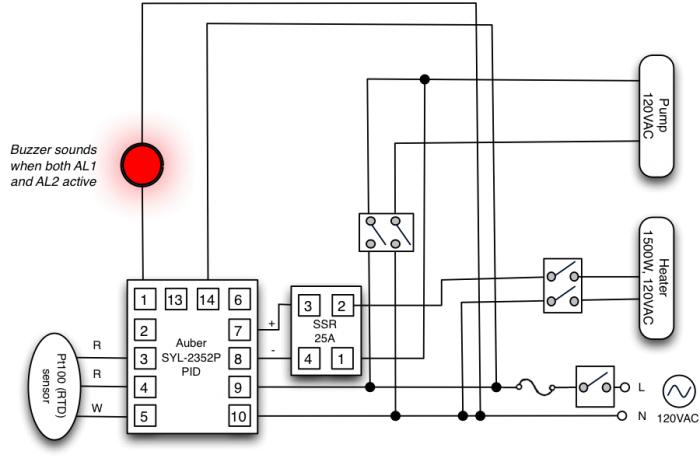

Here's what I put together. The switches have built-in indicator lights when energized. Buzzer sounds at end of mashout (w/proper programming of PID). 15A circuit breaker. Heater disabled when pump turned off. Pump controllable independently.

Borgstrom said:Here's what I put together. The switches have built-in indicator lights when energized. Buzzer sounds at end of mashout (w/proper programming of PID). 15A circuit breaker. Heater disabled when pump turned off. Pump controllable independently.

I hope it works out for you; glad to help.

Not sure what you mean by "difference in control"...however, I wanted to be able to program a step mash, so I chose the 2352P PID for programmability; I wanted the heater enabled only when pump was active, so changed the wiring. I also added a switch just for the heater so I could disable it when just using the pump.

I've only done some basic testing on this up until now, but so far it works exactly as I expected. I'll probably brew again in July, so I'll do a more thorough writeup then.

Borgstrom said:The SYL4342 in the original post has relay connector outputs rated to 1200 watts, but I wanted to use a 1500 watt heater. Edit: Upon closer examination of the circuit in the OP, I don't see how it could work. It has pins 7 and 8 hooked directly to an Auber DC-triggerd SSR. However, pins 7 and 8 on SYL4342 are the NC terminals of a relay according to Auber's diagram. I think the OP used the wrong part number for the PID; it should be SYL4352. This correction was pointed out somewhere earlier in the thread and is actually referenced on Auber's web site; unfortunately the circuit diagram on the OP hasn't been fixed.

I picked the SYL2352P because (a) it had SSR control output and I planned on using a DC-triggered SSR, and (b) it was programmable, allowing me to automate single-step + mash-out ramps, and possibly automate multi-step mashes in the future. It turns out programming the PID required a fair amount study (from what I can tell you are essentially writing machine code for whatever tiny processor they're using). I'm not sure it is worth the extra effort, but will reserve judgement until I do a full brew session with it.

SYL4352P (a newer version equivalent to SYL2352P with about the same specs) would also work, as would the SYL4352 for manual use. Terminal diagram for these is different from my diagram, so you'd have to make the appropriate changes.

In this circuit does the SSR need a heat sink?

jaw94087 said:I believe it does according to Auber Instruments, but I had not included one in the picture. I could have used high current switches and eliminated the relay, but I did not want to use a square switch. I've updated the circuit(picture) using information you guys provided.

Thanks... I figured it did need a heatsink, but wasn't sure. Didn't think to read the instructions for the PID.

I've been following this thread for a while and you've presented a circuit that makes sense to me and just what I need. Thanks.