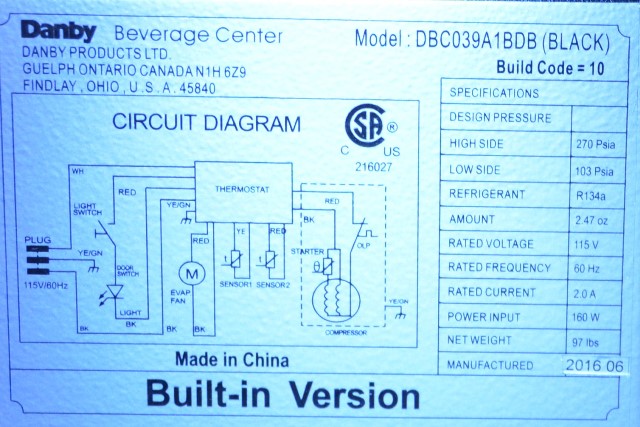

Hoping someone can tell me/point me in the right direction to replace the beverage center temp control with InkBird ITC-1000.

Beverage center schematic.

Thanks.

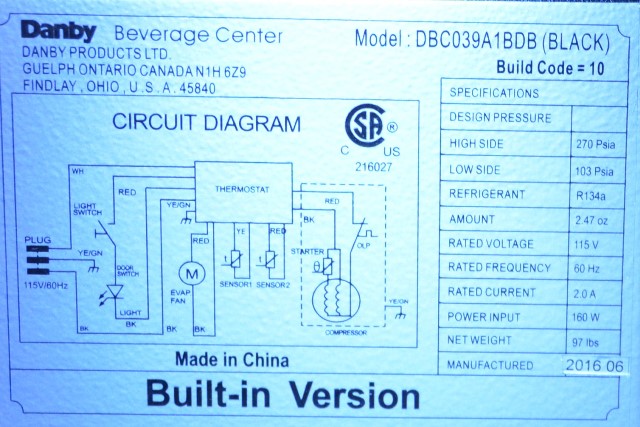

Beverage center schematic.

Thanks.

What happens if you set a temperature, then pull the line cord, then plug it back in?

Does the unit resume with the previously set temperature or does it revert to something else?

Cheers!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)