- Joined

- Jan 6, 2008

- Messages

- 161

- Reaction score

- 19

I've been using the Wifi ITC-308 in combination with a heat pad for controlling my fermentation chamber (a 5cf freezer with collar).

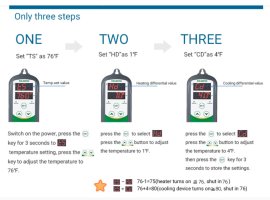

I've got 2 small batches going and wanted to maintain a temp around 70F so as to benefit both yeasts (Wyeast1214 & WL530). My TS is 70, my HD is 1 and my CD is 3. I would have assumed that the heat side would kick in at 69 and turn off at 70 but it doesn't. My cold side kicks in at 73 but takes it down to 68? I use tilts to monitor the temps. I use a thermowell for the probe.

I love that I can check in remotely to monitor the temps, but keep discovering that the cold side control goes down below my set point TS! The heat side goes over the TS as well! Inkbird on their website suggests the temps will turn off at the TS.

Anyone have a cure or a source for a better controller that shuts off at the TS?

I've got 2 small batches going and wanted to maintain a temp around 70F so as to benefit both yeasts (Wyeast1214 & WL530). My TS is 70, my HD is 1 and my CD is 3. I would have assumed that the heat side would kick in at 69 and turn off at 70 but it doesn't. My cold side kicks in at 73 but takes it down to 68? I use tilts to monitor the temps. I use a thermowell for the probe.

I love that I can check in remotely to monitor the temps, but keep discovering that the cold side control goes down below my set point TS! The heat side goes over the TS as well! Inkbird on their website suggests the temps will turn off at the TS.

Anyone have a cure or a source for a better controller that shuts off at the TS?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)