I recently picked up a couple well used Zymatics and I have to say I really appreciate this community being here as I refurbish them. Seems like most of the issues I've run into have already been addressed here and the people I've chatted with have been extremely helpful. Looking forward to many successful brews!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PicoBrew Zymatic

- Thread starter anthropod

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Any Homebrew supply shop or Amazon will have replacement tubing, just be sure to get thick walled (1/8"), high temp, food grade silicone. I usually get my stuff from MoreBeer, Northern Brewer, Midwest Supplies or Austin Homebrew depending upon price and availability.

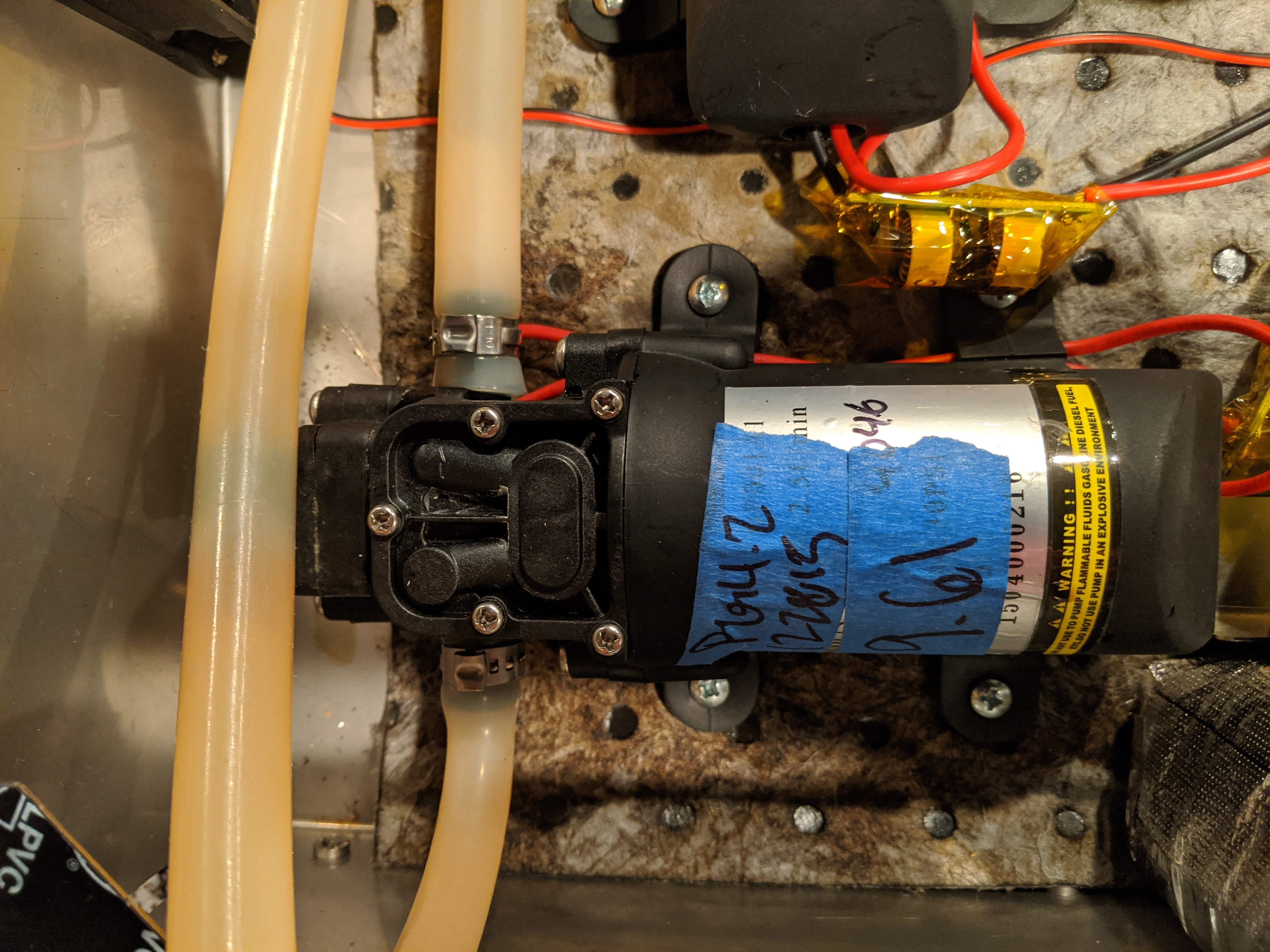

I'd pull those pump heads apart also to make sure the silicone gaskets are ok. Replacement pumps are available for $30 so I wouldn't hesitate to swap them out. Those pics show a very old version of the pumps and could have been part of the original kickstarter.

Glycol replacement will be a must, but you'll be doing that anyway since you are replacing the tubing. Might be a good time to take out the HEX and either soak it in PBW or just replace it and while your at it, the RIMS may need a good cleaning also. The Picobrew recommended cleaning was a joke.

I'd pull those pump heads apart also to make sure the silicone gaskets are ok. Replacement pumps are available for $30 so I wouldn't hesitate to swap them out. Those pics show a very old version of the pumps and could have been part of the original kickstarter.

Glycol replacement will be a must, but you'll be doing that anyway since you are replacing the tubing. Might be a good time to take out the HEX and either soak it in PBW or just replace it and while your at it, the RIMS may need a good cleaning also. The Picobrew recommended cleaning was a joke.

tarwin

Member

- Joined

- Sep 11, 2020

- Messages

- 7

- Reaction score

- 2

Hey guys

I got my hands of a Zymatic with maybe 20 brew under its belt that has lost its brain (Arduino board was send in to Picobrew). What would you say was the best way to get it going again?

- I looked around for a replacement board but found nothing on the usual places. Maybe someone here has a spare to sell?

- I had a look at Elsinore and Brucontrol. Are there any previous trys to implement either one on a Zymatic?

Cheers, Peter

I got my hands of a Zymatic with maybe 20 brew under its belt that has lost its brain (Arduino board was send in to Picobrew). What would you say was the best way to get it going again?

- I looked around for a replacement board but found nothing on the usual places. Maybe someone here has a spare to sell?

- I had a look at Elsinore and Brucontrol. Are there any previous trys to implement either one on a Zymatic?

Cheers, Peter

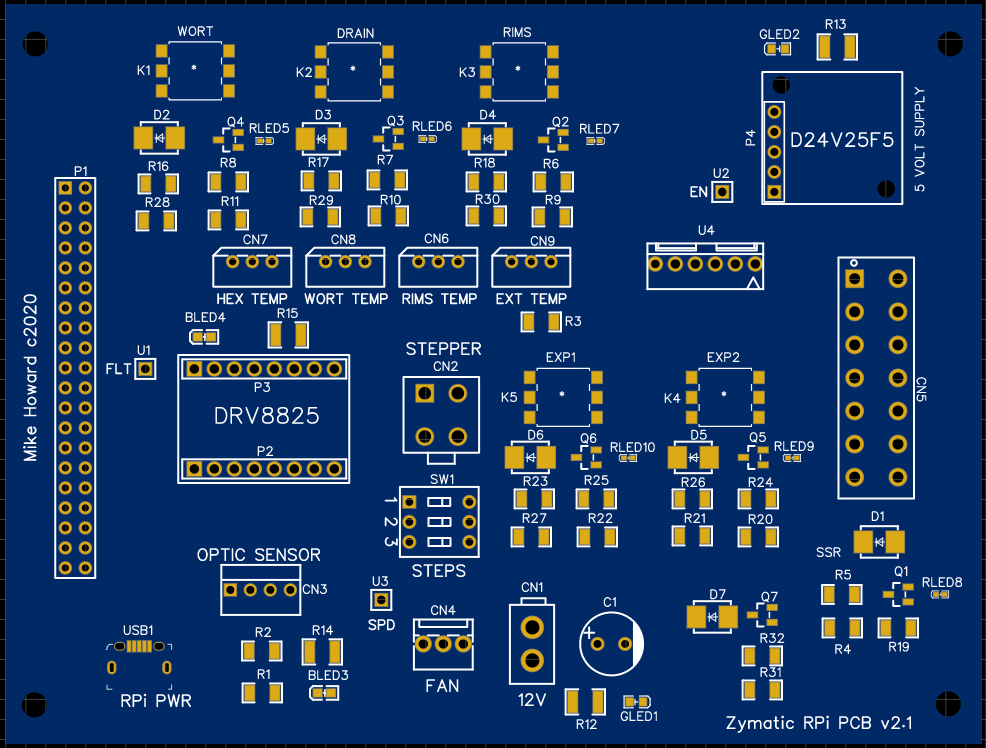

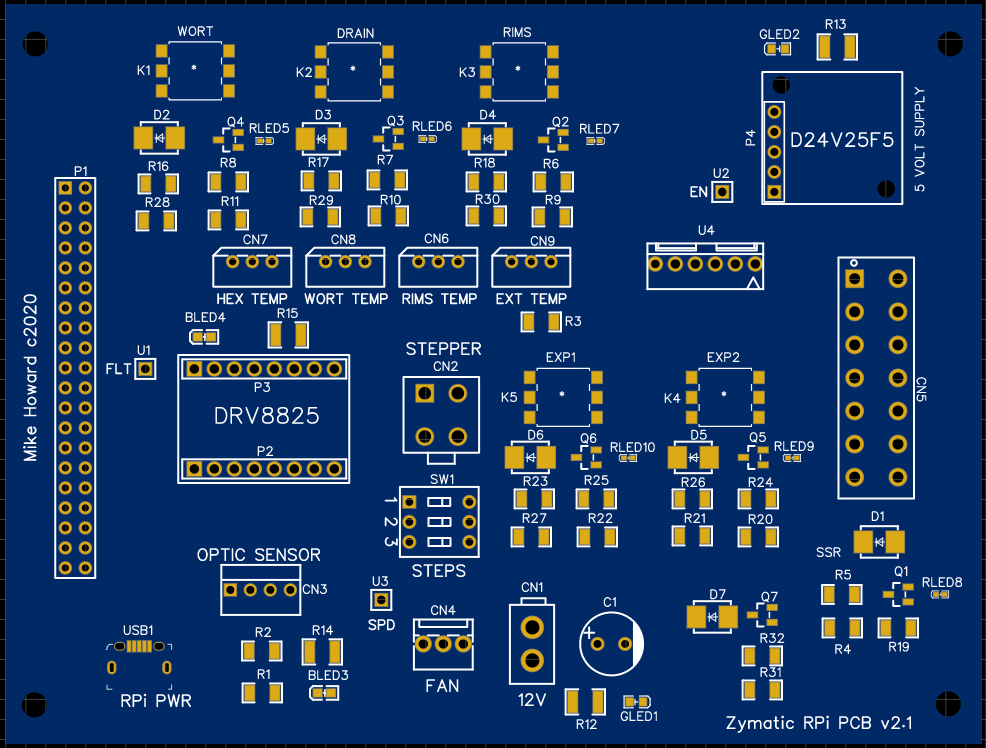

@tarwin hold tight for a bit longer, I am in the process of converting the Zymatics over to a Raspberry Pi with a new PCB. Still several weeks out, but a prototype is on the way. The project will be open source, fully plug and play and offer expansions. In fact, here is revision 2.1 I am currently working on:

This version will offer two more relays to control external components and one more temperature probe. In the works is adding an expansion connector to access the rest of the unused Raspberry Pi pins to allow further external capabilities.

The software has already been developed and is just awaiting version 1 of the board so I can test it in real life.

This version will offer two more relays to control external components and one more temperature probe. In the works is adding an expansion connector to access the rest of the unused Raspberry Pi pins to allow further external capabilities.

The software has already been developed and is just awaiting version 1 of the board so I can test it in real life.

tarwin

Member

- Joined

- Sep 11, 2020

- Messages

- 7

- Reaction score

- 2

Mike, I read the last 20 pages of this thread now, thanks for everything you do for this community!

The new software and pcb really looks great. One question though, you started out with CraftBeerPi3 as I understood and even got the arm to work ... why did you start writing a new node.js tool from scratch?

I'm a member of a local makerspace and know my way around electronics if you need a beta tester. Arduino and Python too (Node not so much). I can source the components and populate the pcb myself if you send one around (which I would gladly pay for of cause). Are you using DirtyPCBs.com?

In the meantime I would love to give the machine an overhaul. Could you send me your manuals as well please? I'm new here so I guess I can't PM you...

thx, Peter

The new software and pcb really looks great. One question though, you started out with CraftBeerPi3 as I understood and even got the arm to work ... why did you start writing a new node.js tool from scratch?

I'm a member of a local makerspace and know my way around electronics if you need a beta tester. Arduino and Python too (Node not so much). I can source the components and populate the pcb myself if you send one around (which I would gladly pay for of cause). Are you using DirtyPCBs.com?

In the meantime I would love to give the machine an overhaul. Could you send me your manuals as well please? I'm new here so I guess I can't PM you...

thx, Peter

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

@tarwin yea, I started out with CraftbeerPi3 but that project appears to be dead and it has a lot of bugs which I didn't want to have to track down right now. I do still plan to revisit it in the future, as I already have all of the actors created and some specialized code. However, I stumbled across Node-Red and it has a lot of traction in the brewing community already. I also figured Node-Red would allow most any person with a reasonable skillset to understand and modify the code.

I'll PM you so I can send the teardown procedures.

I'll PM you so I can send the teardown procedures.

Mike,

Question, have you thought about having the step filter casted out of Tempered Glass like Pyrex? It seams that someone could have them made for the Z / Zymatic, and even Pro / C ?? In my opinion Pico should have made them out of tempered glass to begin with!

Do you have any idea how one would go about this ? I’m sure if it was organized there would be great demand ?

Question, have you thought about having the step filter casted out of Tempered Glass like Pyrex? It seams that someone could have them made for the Z / Zymatic, and even Pro / C ?? In my opinion Pico should have made them out of tempered glass to begin with!

Do you have any idea how one would go about this ? I’m sure if it was organized there would be great demand ?

Mike,

One more question, really topic

I am finding that most of the recipes on Pico.com (for the zymaticthe boil step is typically for 20 minutes. Yet, as I deepen my knowledge on brewing in general, it seems most sources call for a strong rolling boil of 60-90 minutes to help break down proteins, condition sugars and amino acids, production of melanoidins, and evaporate off DMS, dimethyl sulfide?

How do you handle this ? Do you increase the boil time and increase the starting water volume compensate for the evaporation?

Will this significantly aid beer clarity due the break down of proteins? Will leaving the rubber keg cover off durning boil suffice for DMS to evaporate off or should I also remove the step-filter cover?

Lastly, have you found over boiling negatively effecting fullness of body, head retention, & or color?

I know it’s a lot, but it all concerns the boil and I greatly respect your opinion as your expertises goes way beyond just the Pico product! I believe you have a wealth of knowledge on how to adjust the Zymatic to make it reproduce what you are doing on a larger scale!! Thank you for everything you are doing for the community!!!

One more question, really topic

I am finding that most of the recipes on Pico.com (for the zymaticthe boil step is typically for 20 minutes. Yet, as I deepen my knowledge on brewing in general, it seems most sources call for a strong rolling boil of 60-90 minutes to help break down proteins, condition sugars and amino acids, production of melanoidins, and evaporate off DMS, dimethyl sulfide?

How do you handle this ? Do you increase the boil time and increase the starting water volume compensate for the evaporation?

Will this significantly aid beer clarity due the break down of proteins? Will leaving the rubber keg cover off durning boil suffice for DMS to evaporate off or should I also remove the step-filter cover?

Lastly, have you found over boiling negatively effecting fullness of body, head retention, & or color?

I know it’s a lot, but it all concerns the boil and I greatly respect your opinion as your expertises goes way beyond just the Pico product! I believe you have a wealth of knowledge on how to adjust the Zymatic to make it reproduce what you are doing on a larger scale!! Thank you for everything you are doing for the community!!!

StumblingMonk

New Member

- Joined

- Oct 2, 2020

- Messages

- 1

- Reaction score

- 3

Hi @Mike Howard ! I too am having the Error #1 issue, and think it may be the Glycol. Could you please send me your procedure?

And thanks for all the info in this thread!

And thanks for all the info in this thread!

@chagtie I had not thought about a "pyrex" or other borosilicate type of glass for the step filter, though that would definitely work. The whole step filter idea was a good one, but executed improperly...typical for PB. I am going down the stainless steel path with a friend who welds, but that project has stalled a bit. Probably restart that next year and see what we can come up with. I'm just keeping mine usable by super gluing every crack whenever I notice them.

As for boiling, depending upon your recipe, you should be boiling for 60 - 90 minutes and for the Zymatic thats at about 207F degrees. Boiling longer should darken the wort and could increase the bitterness in your beer by releasing unwanted tannins, but I have never tried more than 90 minutes.

As for boiling, depending upon your recipe, you should be boiling for 60 - 90 minutes and for the Zymatic thats at about 207F degrees. Boiling longer should darken the wort and could increase the bitterness in your beer by releasing unwanted tannins, but I have never tried more than 90 minutes.

@StumblingMonk I PM'd you

Russell Whitaker

New Member

Guess what brings me to this forum? The "Fatal Error Occurred / Cancelling Brew / Error #: 1" problem. I have a Zymatic purchased September 2015, apparently assembled by "Dean Chu" - yes, I opened the back, now that the company & warranty no longer exist - which I hadn't used since before having moved from the SF Bay area to the Seattle area a couple of years ago. I finally unboxed the unit and its supplies after a couple of moves, and set it up, intending to restart brewing with it. I ran a rinse, then tried to run a deep clean, with no success. There are a couple of apparently air-locked lines on the top and to the right side as viewed from the open back.

I've read enough in this thread to suspect I need to do HEX glycol loop work. @Mike Howard may I please impose on you myself for a PM of your procedure? I'm fairly technical - an Extra Class ham radio hobbyist with a large, well-equipped workshop - so I'll do what I need to get this Zymatic brewing again. TIA!

I've read enough in this thread to suspect I need to do HEX glycol loop work. @Mike Howard may I please impose on you myself for a PM of your procedure? I'm fairly technical - an Extra Class ham radio hobbyist with a large, well-equipped workshop - so I'll do what I need to get this Zymatic brewing again. TIA!

Russell Whitaker

New Member

Any update? Did the procedures you receive from @Mike Howard work out for you?Hi @Mike Howard ! I too am having the Error #1 issue, and think it may be the Glycol. Could you please send me your procedure?

And thanks for all the info in this thread!

@Russell Whitaker I PM'd you

Russell Whitaker

New Member

I've thanked you elsewhere, @Mike Howard , but for the record I'll do so again here.@Russell Whitaker I PM'd you

This "Error #1" fix worked nicely, and consumed about half a cup of 1/3rd propylene glycol : 2/3rds water mix, after about an hour's careful squeezing of air bubbles out through the HEX loop temperature probe junction. I have one Party Porter in fermentation now, and will be brewing another in the next couple of days, then I'll turn my attention to options for upgrading with a reservoir.

Zymatic is a better machine than the Z !!!

The more that I study the Z , the more I am convinced that Picobrew went backwards in their production quality! The Z is essentially a piece of plastic that is destined to fail over time.

Once the Zymatic is modified to resolve the a Glycol loop (also I recommended switching the glycol loop to the top ports of the heat exchanger and the beer/ wort to the bottom ports ) the machine is solid!! In addition, you can basically source nearly every replacement part on Amazon.

I am convinced that I will not trade in my Zymatic for a Z ever !

P.s. Please someone figure out how to have the Step filters reproduced out of tempered glass!

The more that I study the Z , the more I am convinced that Picobrew went backwards in their production quality! The Z is essentially a piece of plastic that is destined to fail over time.

Once the Zymatic is modified to resolve the a Glycol loop (also I recommended switching the glycol loop to the top ports of the heat exchanger and the beer/ wort to the bottom ports ) the machine is solid!! In addition, you can basically source nearly every replacement part on Amazon.

I am convinced that I will not trade in my Zymatic for a Z ever !

P.s. Please someone figure out how to have the Step filters reproduced out of tempered glass!

Russell Whitaker

New Member

Once the Zymatic is modified to resolve the a Glycol loop (also I recommended switching the glycol loop to the top ports of the heat exchanger and the beer/ wort to the bottom ports ) the machine is solid!! In addition, you can basically source nearly every replacement part on Amazon.

I'm pleased and reassured to hear this, and suspected this to be the case when I disassembled the unit to fix my original issue. Would you happen to have pointers to:

1.) an optimal replacement BOM (bill of materials) and instructions for the improved glycol loop;

2.) the same for the wort loop;

3.) the specs for those replacement parts?

Thanks!

Picobrew Zymatic owner that is also suffering from Fatal Error #1 and 17.

Was slick for almost the entire summer...set the advanced machine settings to heat at 7 degrees at a clip and then hold for 3 minutes. Getting from room temp to about 150 was a painful process having to 'Next Step' after countless errors. But once heated, Zymatic still ran like a champ.

Alas, maybe it's the cooler temperature in my garage, but I can't get it to heat. Took over an hour to get 2.5 gallons of water for a cleaning cycle to get from 118 to 125, then I flat gave up.

@Mike Howard - Please share your glycol loop process with me...you're my only hope.

Was slick for almost the entire summer...set the advanced machine settings to heat at 7 degrees at a clip and then hold for 3 minutes. Getting from room temp to about 150 was a painful process having to 'Next Step' after countless errors. But once heated, Zymatic still ran like a champ.

Alas, maybe it's the cooler temperature in my garage, but I can't get it to heat. Took over an hour to get 2.5 gallons of water for a cleaning cycle to get from 118 to 125, then I flat gave up.

@Mike Howard - Please share your glycol loop process with me...you're my only hope.

On Facebook “Picobrewer” Z owners are experiencing Error 6. It does not seam to be known yet I believe that it is just the Z’s version of the Zymatic “Error 1”. Basically, the machines are over heating due to a flow issue in the heat exchanger and/or low water in the heat loop. First, make sure the heat loop on the Z is topped of with distilled water. As for the Zymatic see Mike Howard’s Glycol top off procedure. The cause for pore flow on the Z is the heat exchanger gets build up and scaling.

It is basically in issue that Pico Brew tried to solve yet possibly failed to do so.

Mike Howard did tremendous work in identifying and solving the Glycol Loop issue. I believe one area of improvement upon his modification is to flip the Heat exchanger so that the Glycol loop is on the top ports as to allow air bubbles to escape, and beer loop is on the bottom so that sticky wort (beer) can fully be drained and cleaned away. If not otherwise, wort residue builds up in the heat exchanger. (See 5th picture)

How the Z is designed only exacerbates the Issue of Wort (beer) not being able to full drain and be cleaned out of the heat exchanger. The Heat exchanger needs to be mounted on its side with the beer loop on the bottom and heat loop on the top just like the Zymatic. You can easily do so with Zip ties. The “Error 6” for many machines are caused by restrictive flow in the heat exchanger due to wort build up!

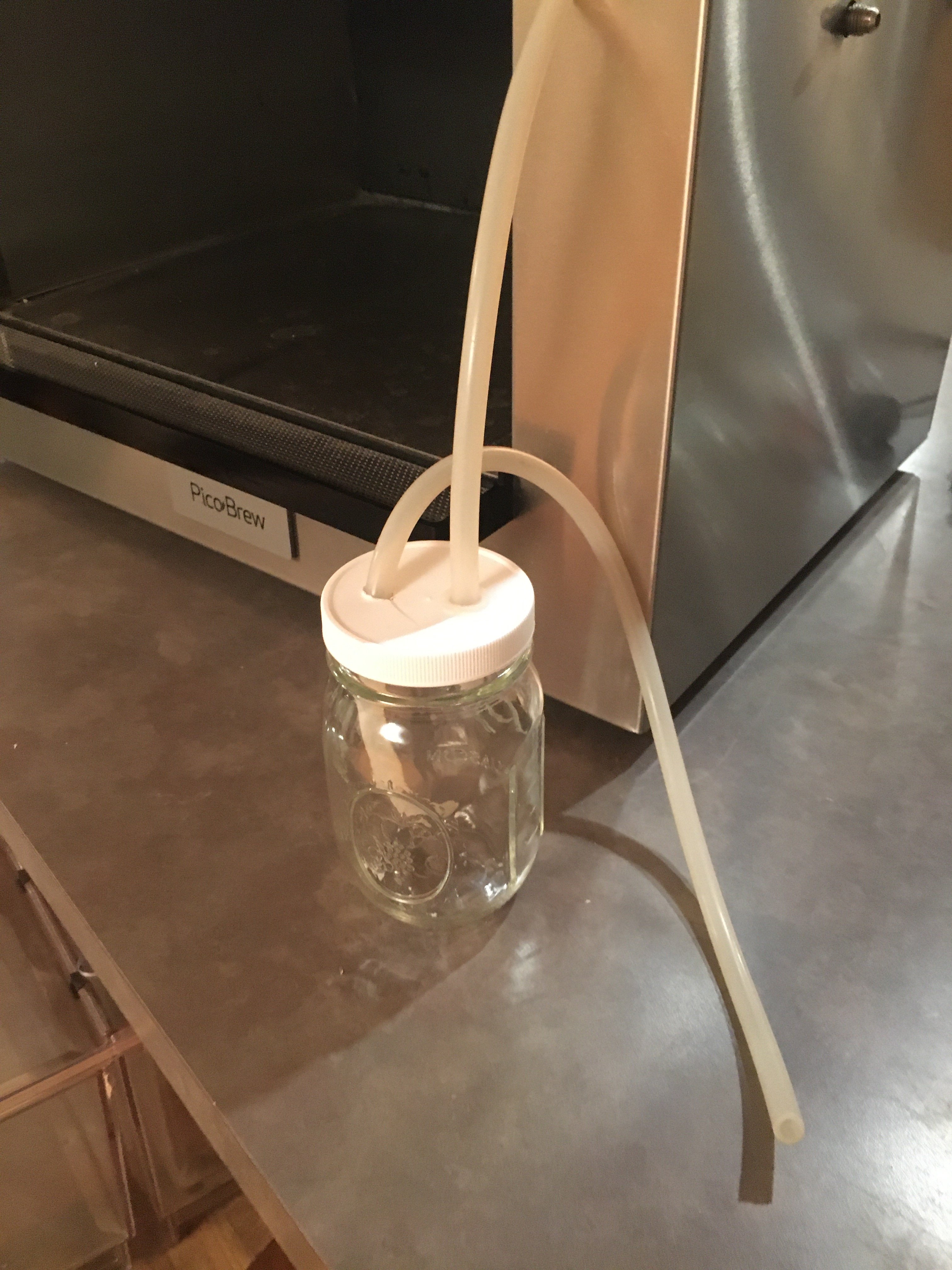

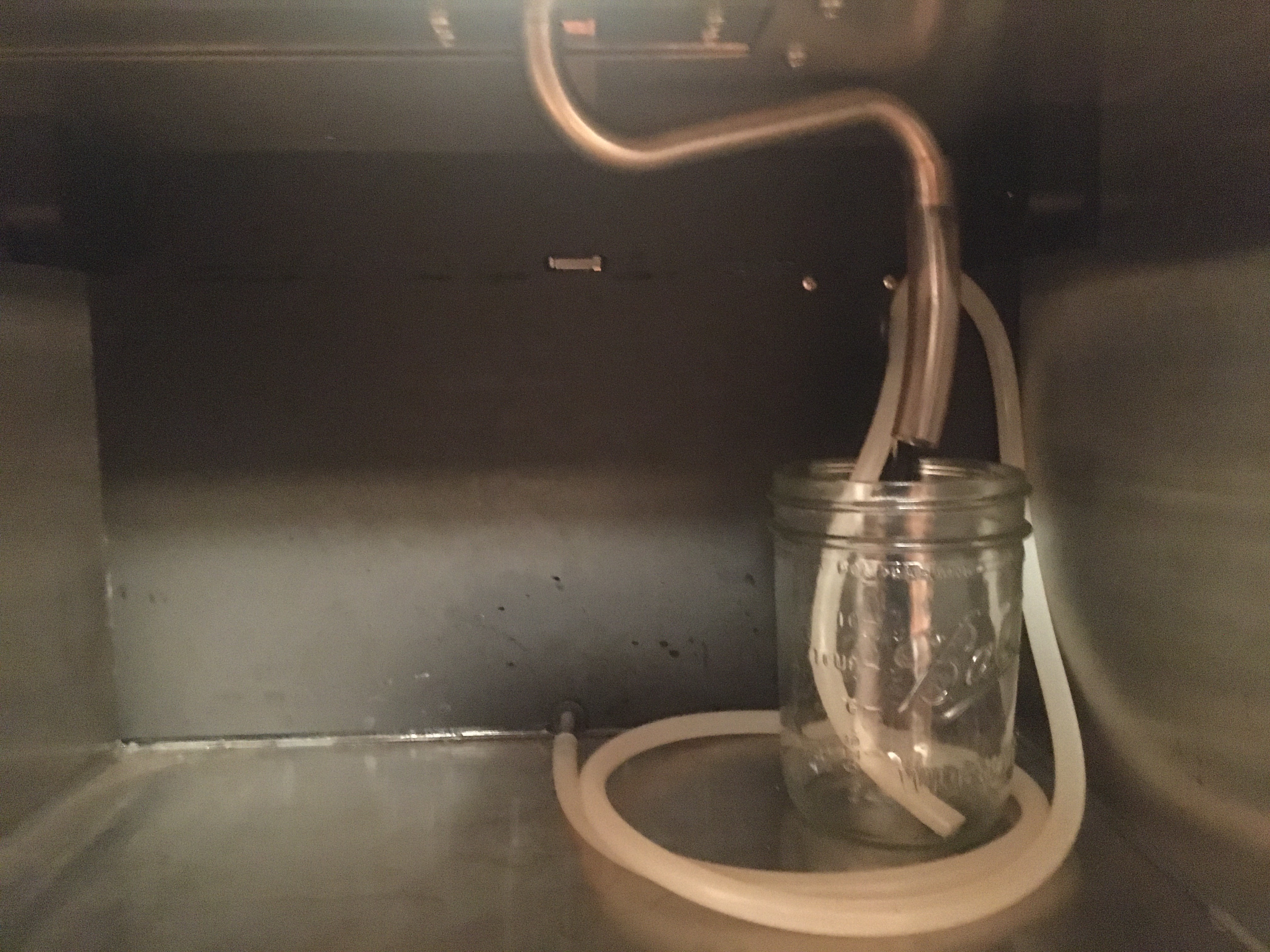

Once you do the modifications, the final and ongoing solution is to build a basic cleaning vessel. I believe a basic Masson Jar is cheep and effective.

The 1st and 3rd pictures are Option 1 for a Zymatic or Z: Place the long hose into the return (inlet) , and place the jar under the bypass.

The 2cd & 4th pictures is a second option a Zymatic or a Z. (Update second option for Zymatic at the bottom of the post)

For Option 2 design for a Z, place the long hose into the return on the bottom of the machine (inlet) and the short hose in the out port of the Z on the ceiling.

This should resolve the issue of not being able to use stronger cleaners that will breakdown protein build up such as PBW , Oxi-clean, Beer Stone Remover; as the stronger cleaners can destroy the plastic Step filter.

You simply run a modifid “clean cycle with PBW” on a heated bypass of 150F for 30 minutes, then run a regular rinse with water only.

Also imagine how much more sanitary your machine will be !

If someone would source a “Pyrex Glass Step Filter” non of this would be an issue!

I hope this helps! Please share to the Facebook guys if you like.

P.s adding a piece of hose to the rotating arm will help with splashing. You can even make the option like Picture # 2 above for the Zymatic (sealed).

Cheers !

Last edited:

jm_maclaren

Active Member

- Joined

- Nov 13, 2020

- Messages

- 30

- Reaction score

- 6

I picked a used Zymatic and it had the fatal error 1. Mike would you be willing to share your instructions for addressing the problem. Thanks, James

Blasterv15

New Member

- Joined

- Nov 17, 2020

- Messages

- 1

- Reaction score

- 0

StumblingMonk,Hi @Mike Howard ! I too am having the Error #1 issue, and think it may be the Glycol. Could you please send me your procedure?

And thanks for all the info in this thread!

Can you send me the glycol fix that Mike suggests. I am also having the Error #1 on the Picobrew Z. I have tried countless times of cleaning, deep cleaning, etc that Mike suggested on one of his post with no success.

@jm_maclaren i sent you a PM

@Blasterv15 PM sent

jm_maclaren

Active Member

- Joined

- Nov 13, 2020

- Messages

- 30

- Reaction score

- 6

Mike. I read your troubleshooting guide and have a non pico keg which you indicated may have too low a tube. The error 1 occurred in a deep clean and my first use. I note before failing - about 1-2 mins in - water was circulating fine. Does that just point to the glycol issue to you?

Not necessarily, but it is a common issue. I'd say if you have done all of the other checks and ran my modified warm up recipe, then that points to the glycol.

BTW, the glycol will evap with the unit just sitting there not being used. It is not a 100% completely sealed closed loop. The addition of an external fill port will save you hours of headaches after you are back running (best mod I've made to date). In fact, I'd say the fill port is really all you need if you don't want to add the reservoir mod.

BTW, the glycol will evap with the unit just sitting there not being used. It is not a 100% completely sealed closed loop. The addition of an external fill port will save you hours of headaches after you are back running (best mod I've made to date). In fact, I'd say the fill port is really all you need if you don't want to add the reservoir mod.

jm_maclaren

Active Member

- Joined

- Nov 13, 2020

- Messages

- 30

- Reaction score

- 6

i searched but didn't find the modified warm up. Is that doing a clean with hot water in the keg? I have Ender's server running on a linux machine and am not accessing picobrew.com servers. Does your write indicate adding a port?

jm_maclaren

Active Member

- Joined

- Nov 13, 2020

- Messages

- 30

- Reaction score

- 6

Also as a ps. I ran the diagnostics and when it came to the heat pump test I couldn’t see or hear anything. Is this related to a glycol issue or a broken pump

Somewhere back in this thread I posted a quick recipe you could use to check your system, however, its not necessary. I'd just go ahead and disassemble the unit and do a thorough clean and top off the glycol. It can't hurt and will let you inspect the lower end since this is a used machine.

The procedure I sent you is only for topping off the glycol, not for any mods. However, for a fill port, you would place a "T" connector between the HEX and the Glycol pump and run a length of tubing up the left side of the unit to a bulkhead fitting near the top. It acts as a small reservoir and allows filling without disassembly in the future. Look back in this thread a few pages and you can see/read about the basics.

The procedure I sent you is only for topping off the glycol, not for any mods. However, for a fill port, you would place a "T" connector between the HEX and the Glycol pump and run a length of tubing up the left side of the unit to a bulkhead fitting near the top. It acts as a small reservoir and allows filling without disassembly in the future. Look back in this thread a few pages and you can see/read about the basics.

View attachment 706796View attachment 706786View attachment 706789View attachment 706790

View attachment 706794

On Facebook “Picobrewer” Z owners are experiencing Error 6. It does not seam to be known yet I believe that it is just the Z’s version of the Zymatic “Error 1”. Basically, the machines are over heating due to a flow issue in the heat exchanger and/or low water in the heat loop. First, make sure the heat loop on the Z is topped of with distilled water. As for the Zymatic see Mike Howard’s Glycol top off procedure. The cause for pore flow on the Z is the heat exchanger gets build up and scaling.

It is basically in issue that Pico Brew tried to solve yet possibly failed to do so.

Mike Howard did tremendous work in identifying and solving the Glycol Loop issue. I believe one area of improvement upon his modification is to flip the Heat exchanger so that the Glycol loop is on the top ports as to allow air bubbles to escape, and beer loop is on the bottom so that sticky wort (beer) can fully be drained and cleaned away. If not otherwise, wort residue builds up in the heat exchanger. (See 5th picture)

How the Z is designed only exacerbates the Issue of Wort (beer) not being able to full drain and be cleaned out of the heat exchanger. The Heat exchanger needs to be mounted on its side with the beer loop on the bottom and heat loop on the top just like the Zymatic. You can easily do so with Zip ties. The “Error 6” for many machines are caused by restrictive flow in the heat exchanger due to wort build up!

Once you do the modifications, the final and ongoing solution is to build a basic cleaning vessel. I believe a basic Masson Jar is cheep and effective.

The 1st and 3rd pictures are Option 1 for a Zymatic or Z: Place the long hose into the return (inlet) , and place the jar under the bypass.

The 2cd & 4th pictures is a second option a Zymatic or a Z. (Update second option for Zymatic at the bottom of the post)

For Option 2 design for a Z, place the long hose into the return on the bottom of the machine (inlet) and the short hose in the out port of the Z on the ceiling.

This should resolve the issue of not being able to use stronger cleaners that will breakdown protein build up such as PBW , Oxi-clean, Beer Stone Remover; as the stronger cleaners can destroy the plastic Step filter.

You simply run a modifid “clean cycle with PBW” on a heated bypass of 150F for 30 minutes, then run a regular rinse with water only.

Also imagine how much more sanitary your machine will be !

If someone would source a “Pyrex Glass Step Filter” non of this would be an issue!

I hope this helps! Please share to the Facebook guys if you like.

View attachment 706797

P.s adding a piece of hose to the rotating arm will help with splashing. You can even make the option like Picture # 2 above for the Zymatic (sealed).

Cheers !

Attachments

this is a follow up from the earlier post (see above)... I believe this is a great solution to be able to deep clean HEX and maintain your Zymatic with PBW or other strong cleaners, without worry of damaging you StepFilter.

Last edited:

jm_maclaren

Active Member

- Joined

- Nov 13, 2020

- Messages

- 30

- Reaction score

- 6

I have a question about the zymatic step filter. I have three pieces and not sure what order they go back into the step filter. There is the duck bill valve and two seals. I have a picture of the three. One looks like a plastic washer and the other a small tube. Thanks!!

Attachments

I have a question about the zymatic step filter. I have three pieces and not sure what order they go back into the step filter. There is the duck bill valve and two seals. I have a picture of the three. One looks like a plastic washer and the other a small tube. Thanks!!

JM_ Maclaren ,

The order is:

- the black duckbill goes in first , with the duckbill side inwards

- then the silicon seal,

- then the hard plastic ring with the concaved side out.

jm_maclaren

Active Member

- Joined

- Nov 13, 2020

- Messages

- 30

- Reaction score

- 6

Thanks!!JM_ Maclaren ,

The order is:

Note: the black Duckbill and the silicon seal is suppose to be glued together. You might notice glue residue on both. You should be able to glue them back together with some silicon sealant. I don't believe it will be a big deal if you don't glue them back together as long as they are in the correct order.

- the black duckbill goes in first , with the duckbill side inwards

- then the silicon seal,

- then the hard plastic ring with the concaved side out.

As talked about chagtag this "simple" cleaning vessel isn't needed for the newer Z Series devices. There is a proper "passthru" that doesn't involve the step filter at all (touches both drain and keg pumps while also going through the HEX and rotary valve position #5/P).

Here is the offline server "recipe" I have custom created for a real good deepcleaning scrub... I've run this 3-4 times with clean solution each time and still getting gunk out of the HEX and internal hoses. If you are used to PBW it would be easy to tell you that my tubing and even the luer-lock T connector are nearly brand new (bye bye beer stone). First 2 runs there was chunks of black/dark brown bits (protein build up) laying at the bottom of the keg.

It is best to start the deepclean, if you are encountering Error 1 during heat phases, at the closest temp to your HOTTEST tap water available. This will jump start the cleaning process and bypass the need to heat COLD tap water.

After 2-3 cleans or when liquid is ending up in the keg mostly clear/clean move on to the next step which is an Acid Rinse/Clean. To test to see if the Error 1 is resolved by the deepclean I've relied on an Acid Rinse with the machine's built in clean, but you could also repurpose the "PBW Deepclean" or a shorter modified "Acid Rinse or Clean" also included below. The purpose of the acid rinse is to inactivate the active ingredient in PBW I typically use Citric Acid for this in the Pico while using Starsan when cleaning kegs and other SS equipment.

After the Acid Rinse run a normal cleaning cycle after the machine has had a chance to cool down (if the wort temp is low and the HEX is >26 degrees higher Error 1 is tripped) or you can run a "Circulate" utility to get the temps to equalize to the incoming tap water temperatures. After this normal cleaning cycle is successful run 2 rinses to make sure all cleaner in the machine is flushed and replaced with water.

At this time given there are no channels for easy step filter replacement (all from the earlier auction have sold out by various folks in the community for an emergency backup and/or for modifications and measuring for molds) I don't recommend running a PBW wash through any other "Location" other than "PassThru" which by-passes the Step Filter. Given the beatings that earlier Zymatic SFs took from owners using PBW and only 1 year of the Z in the hands of the community we don't yet have long term wear statistics for the Z's newly designed SF. Cleaning this in a dishwasher or by hand is best (in addition to the build in "clean" utility function on the device).

Here is the offline server "recipe" I have custom created for a real good deepcleaning scrub... I've run this 3-4 times with clean solution each time and still getting gunk out of the HEX and internal hoses. If you are used to PBW it would be easy to tell you that my tubing and even the luer-lock T connector are nearly brand new (bye bye beer stone). First 2 runs there was chunks of black/dark brown bits (protein build up) laying at the bottom of the keg.

It is best to start the deepclean, if you are encountering Error 1 during heat phases, at the closest temp to your HOTTEST tap water available. This will jump start the cleaning process and bypass the need to heat COLD tap water.

After 2-3 cleans or when liquid is ending up in the keg mostly clear/clean move on to the next step which is an Acid Rinse/Clean. To test to see if the Error 1 is resolved by the deepclean I've relied on an Acid Rinse with the machine's built in clean, but you could also repurpose the "PBW Deepclean" or a shorter modified "Acid Rinse or Clean" also included below. The purpose of the acid rinse is to inactivate the active ingredient in PBW I typically use Citric Acid for this in the Pico while using Starsan when cleaning kegs and other SS equipment.

After the Acid Rinse run a normal cleaning cycle after the machine has had a chance to cool down (if the wort temp is low and the HEX is >26 degrees higher Error 1 is tripped) or you can run a "Circulate" utility to get the temps to equalize to the incoming tap water temperatures. After this normal cleaning cycle is successful run 2 rinses to make sure all cleaner in the machine is flushed and replaced with water.

At this time given there are no channels for easy step filter replacement (all from the earlier auction have sold out by various folks in the community for an emergency backup and/or for modifications and measuring for molds) I don't recommend running a PBW wash through any other "Location" other than "PassThru" which by-passes the Step Filter. Given the beatings that earlier Zymatic SFs took from owners using PBW and only 1 year of the Z in the hands of the community we don't yet have long term wear statistics for the Z's newly designed SF. Cleaning this in a dishwasher or by hand is best (in addition to the build in "clean" utility function on the device).

As talked about chagtag this "simple" cleaning vessel isn't needed for the newer Z Series devices. There is a proper "passthru" that doesn't involve the step filter at all (touches both drain and keg pumps while also going through the HEX and rotary valve position #5/P).

Here is the offline server "recipe" I have custom created for a real good deepcleaning scrub... I've run this 3-4 times with clean solution each time and still getting gunk out of the HEX and internal hoses. If you are used to PBW it would be easy to tell you that my tubing and even the luer-lock T connector are nearly brand new (bye bye beer stone). First 2 runs there was chunks of black/dark brown bits (protein build up) laying at the bottom of the keg.

It is best to start the deepclean, if you are encountering Error 1 during heat phases, at the closest temp to your HOTTEST tap water available. This will jump start the cleaning process and bypass the need to heat COLD tap water.

View attachment 707305

After 2-3 cleans or when liquid is ending up in the keg mostly clear/clean move on to the next step which is an Acid Rinse/Clean. To test to see if the Error 1 is resolved by the deepclean I've relied on an Acid Rinse with the machine's built in clean, but you could also repurpose the "PBW Deepclean" or a shorter modified "Acid Rinse or Clean" also included below. The purpose of the acid rinse is to inactivate the active ingredient in PBW I typically use Citric Acid for this in the Pico while using Starsan when cleaning kegs and other SS equipment.

View attachment 707306

After the Acid Rinse run a normal cleaning cycle after the machine has had a chance to cool down (if the wort temp is low and the HEX is >26 degrees higher Error 1 is tripped) or you can run a "Circulate" utility to get the temps to equalize to the incoming tap water temperatures. After this normal cleaning cycle is successful run 2 rinses to make sure all cleaner in the machine is flushed and replaced with water.

At this time given there are no channels for easy step filter replacement (all from the earlier auction have sold out by various folks in the community for an emergency backup and/or for modifications and measuring for molds) I don't recommend running a PBW wash through any other "Location" other than "PassThru" which by-passes the Step Filter. Given the beatings that earlier Zymatic SFs took from owners using PBW and only 1 year of the Z in the hands of the community we don't yet have long term wear statistics for the Z's newly designed SF. Cleaning this in a dishwasher or by hand is best (in addition to the build in "clean" utility function on the device).

Trevor,

Thanks for follow up and update on the cleaning process for the Z. This recipe will work great for the Zymatic with the glass cleaning vessel !

Will edit the post to reflect the update.

View attachment 706796View attachment 706786View attachment 706789View attachment 706790

View attachment 706794

On Facebook “Picobrewer” Z owners are experiencing Error 6. It does not seam to be known yet I believe that it is just the Z’s version of the Zymatic “Error 1”. Basically, the machines are over heating due to a flow issue in the heat exchanger and/or low water in the heat loop. First, make sure the heat loop on the Z is topped of with distilled water. As for the Zymatic see Mike Howard’s Glycol top off procedure. The cause for pore flow on the Z is the heat exchanger gets build up and scaling.

It is basically in issue that Pico Brew tried to solve yet possibly failed to do so.

Mike Howard did tremendous work in identifying and solving the Glycol Loop issue. I believe one area of improvement upon his modification is to flip the Heat exchanger so that the Glycol loop is on the top ports as to allow air bubbles to escape, and beer loop is on the bottom so that sticky wort (beer) can fully be drained and cleaned away. If not otherwise, wort residue builds up in the heat exchanger. (See 5th picture)

How the Z is designed only exacerbates the Issue of Wort (beer) not being able to full drain and be cleaned out of the heat exchanger. The Heat exchanger needs to be mounted on its side with the beer loop on the bottom and heat loop on the top just like the Zymatic. You can easily do so with Zip ties. The “Error 6” for many machines are caused by restrictive flow in the heat exchanger due to wort build up!

Once you do the modifications, the final and ongoing solution is to build a basic cleaning vessel. I believe a basic Masson Jar is cheep and effective.

The 1st and 3rd pictures are Option 1 for a Zymatic or Z: Place the long hose into the return (inlet) , and place the jar under the bypass.

The 2cd & 4th pictures is a second option a Zymatic or a Z. (Update second option for Zymatic at the bottom of the post)

For Option 2 design for a Z, place the long hose into the return on the bottom of the machine (inlet) and the short hose in the out port of the Z on the ceiling.

This should resolve the issue of not being able to use stronger cleaners that will breakdown protein build up such as PBW , Oxi-clean, Beer Stone Remover; as the stronger cleaners can destroy the plastic Step filter.

You simply run a modifid “clean cycle with PBW” on a heated bypass of 150F for 30 minutes, then run a regular rinse with water only.

Also imagine how much more sanitary your machine will be !

If someone would source a “Pyrex Glass Step Filter” non of this would be an issue!

I hope this helps! Please share to the Facebook guys if you like.

View attachment 706797

P.s adding a piece of hose to the rotating arm will help with splashing. You can even make the option like Picture # 2 above for the Zymatic (sealed).

Cheers !

Update: working with Trever Mack, he informed me that the Z has a proper "passthrough" without the need of the step filter, therefor this cleaning vessel is only needed for the Zymatic.

Great props to Trevor, after some troubleshooting, the solution for the Z "error 6" has been resolved, and a cleaning recipe !

His cleaning steps can be used for a deep clean on the Zymatic too. After the Heat Exchanger is completely cleaned out with PBW, do modify the machine by turning the Heat Exchanger on its side to prevent this from occurring again.

I would make it part of everyone's brewing process to run a PBW - 30min passthrough recipe after each brew, then a basic rinse. (see Trevor Mack's post above)

Similar threads

- Replies

- 7

- Views

- 2K

- Replies

- 4

- Views

- 3K

- Locked

- Replies

- 1

- Views

- 1K