New to the group so hello to everyone. Long time follower and this is my first post. Here's the situation, I have 2 spike cf30 unitanks, I'm thinking of sticking a sticking a 4500w ss element where the sampling port is and doing a big all in one biab 130 liter setup. Boil, steep, ferment, and carbonate all in one container without ever moving liquid to another tank except for kegging at the very end. I've only been brewing about a year and was hoping someone could point out the downfalls to a setup like this. 4500w element with pid controller for heat and immersion chiller for cooling. Also have conical heating pad to maintain heat during ferment if need be (brewing in unheated garage at 3c). Looking forward to advice for you brew gods!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

One vessel system advice.

- Thread starter Mord

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

BIAB is really the simplest beer brewing system, but I don't know if it works with 130 liters. Instead of a bag, you should use a metal strainer and some kind of power-driven lifting and straining system.

Also, I think the 4500W heater power is too weak for 130 liters of wort. I have 2000W for 30 liters, but I would be happier with a little more.

Also, I think the 4500W heater power is too weak for 130 liters of wort. I have 2000W for 30 liters, but I would be happier with a little more.

I don't think the metal strainer will work because of the weird angle the heating element sticks up at. The grain bill is about 55 pounds so I'll be bringing approximately 70 liters up to 150ish. My 5500w element will bring 50 liters to a boil in about 45 minutes in my other toy  . So basically I'm figuring an hour to get it to 150, stay at 150 for an hour, then bring volume up to 130 liters and bring to a boil from whatever temperature it drops to. I'm guessing about 4-5 hours total. I wonder if 2 separate bags would work?

. So basically I'm figuring an hour to get it to 150, stay at 150 for an hour, then bring volume up to 130 liters and bring to a boil from whatever temperature it drops to. I'm guessing about 4-5 hours total. I wonder if 2 separate bags would work?

Two separate bags would work, but it's also twice the work and equipment. Although, I think that 65 liters is too much to lift without a crane. In addition, it is 9000W of mains power. I don't know how it works in Canada. In Europe, they would need three-phase current for that power.

The maximum my brew space is wired for is 30 amp for my welder plug. I think I might just have to try a test run on just water to see if it's possible, and if not I'll have to use propane and a different boiler pot. I was trying to avoid buying another pot as I don't think my 80 liter is big enough.

I am currently brewing a double-strength wort that I dilute with water after cooling and then pitch yeast and that works perfectly. I came up with this idea after I read this Brulosophy test. This saves energy, time, water and the size of the brewing pot, without sacrificing quality.

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

That's basically what I've been doing until this crazy idea came into my head. For some reason I never thought of doing it in the conical like that. Then my max boil would be 70-80 liters then add remainder at the end. I wish me and my brain were on the same page a little more often.I am currently brewing a double-strength wort that I dilute with water after cooling and then pitch yeast and that works perfectly. I came up with this idea after the Brulosophy test. This saves energy, time, water and the size of the brewing pot, without sacrificing

DuncB

Well-Known Member

Why not just sparge your grains more to dilute it?

Rather than liquoring back an inefficiently made first runnings.

Rather than liquoring back an inefficiently made first runnings.

Also a great idea. This is why I come to you people! Thanks.Why not just sparge your grains more to dilute it?

Rather than liquoring back an inefficiently made first runnings.

Brewing stronger wort, and then diluting will give you a lauter efficiency hit. Lauter efficiency gets lower as the grain bill weight to pre-boil volume increases. You can compensate by using more grain, if dilution is the way you want to go.I am currently brewing a double-strength wort that I dilute with water after cooling and then pitch yeast and that works perfectly. I came up with this idea after I read this Brulosophy test. This saves energy, time, water and the size of the brewing pot, without sacrificing quality.

As far as how large a batch you can do with BIAB - take a look here.

Brew on

Be sure the gaskets can take the heat.

Was going to switch out to silicone but thanks.Be sure the gaskets can take the heat.

Silicone gaskets/"O" rings are the worst (by an order of magnitude or more) as far as oxygen permeability is concerned, and should be avoided in fermentation and storage vessels.Was going to switch out to silicone but thanks.

Brew on

Really? I've never thought or heard of that before. I'm coming from the distilling world where it wasn't much of a concern.Silicone gaskets/"O" rings are the worst (by an order of magnitude or more) as far as oxygen permeability is concerned, and should be avoided in fermentation and storage vessels.

Brew on

Epdm?Really? I've never thought or heard of that before. I'm coming from the distilling world where it wasn't much of a concern.

Epdm?

Quick search on the googles suggest epdm gaskets can handle temps from -50F to 300F.

EDPM is about an order of magnitude better than silicone, but still relatively high permeability vs. other polymers.Epdm?

Brew on

Brewing stronger wort, and then diluting will give you a lauter efficiency hit. Lauter efficiency gets lower as the grain bill weight to pre-boil volume increases. You can compensate by using more grain, if dilution is the way you want to go.

As far as how large a batch you can do with BIAB - take a look here.

Brew on

Yes, of course it is possible to make a BIAB for such large quantities, but, as we see here, not without a crane and a bag made of strong material.

not without a crane and a bag made of strong material.

... and, I'm betting, more power than OP's 30A circuit can deliver.

Brewing stronger wort, and then diluting will give you a lauter efficiency hit. Lauter efficiency gets lower as the grain bill weight to pre-boil volume increases. You can compensate by using more grain, if dilution is the way you want to go.

As far as how large a batch you can do with BIAB - take a look here.

Brew on

The BIAB method has no problems with mash tun lautern, and sparge is not commonly used. With larger amounts of grain, I only have a problem with the heavier bag and longer squeezing the bag. As long as there is at least 2.5 times more water than grain (2.5 liters of water per kilogram of grain), there are no problems with efficiency, and I did not feel the reduced bitterness of the hops.

... and, I'm betting, more power than OP's 30A circuit can deliver.

With a 120V power distribution system and a 4500W heater, the calculation says that 37.5A is needed. If 240V is used, less than 19A is needed, which means that a 30A plug would be sufficient.

Glad you're seeing it that way. Sometimes ideas sound good until you start sorting out the details.All you people are making me think I should be looking at a hellfire burner and a big ass pot. Thanks for all your help and saving me a LOT of time to avoid the crazy plan.

I'm impressed that you have been brewing for a short time and have TWO CF30's. I have the CF10 and love it!

During covid a ton of micro breweries started up in my area and now the are slowly closing the doors on them and they're selling of the equipment very cheap. Like silly cheap.Glad you're seeing it that way. Sometimes ideas sound good until you start sorting out the details.

I'm impressed that you have been brewing for a short time and have TWO CF30's. I have the CF10 and love it!

Good deal! Hard to pass up great deals.During covid a ton of micro breweries started up in my area and now the are slowly closing the doors on them and they're selling of the equipment very cheap. Like silly cheap.

30A will readily deliver more than 4500 watts. 5500 easily. But will 4500 (or even 5500) watts boil 100+ liters? That's what I'm doubting.sufficient

Seems academic, as OP has decided against the electric conical BIAB. Probably wisely.

Yes you are correct. I'm going with 2 separate boils in an 80 liter pot with a 5500w element. I was just trying to avoid getting a pump and hoses. This while buy once cry once thing is getting expensive lol30A will readily deliver more than 4500 watts. 5500 easily. But will 4500 (or even 5500) watts boil 100+ liters? That's what I'm doubting.

Seems academic, as OP has decided against the electric conical BIAB. Probably wisely.

Yes, for more than a five gallon batch, you need some kind of pulley system (unless you are a serious weightlifter.) A hoist is nice if you like toys and have the funds. Many of us use pulleys even for 5 gal batches. You don't necessarily need a "crane", just something to hang the pulley from. Ceiling joists work well, as do tall step ladders, deer hanging tripods, engine hoists - there are lots of possibilities.Yes, of course it is possible to make a BIAB for such large quantities, but, as we see here, not without a crane and a bag made of strong material.

The bag does not need any special "strong material" the bag for the 145 gal (280+ lb grain bill) is made out of the same material as the smaller bags that Wilser makes. The material is much stronger than it looks.

Brew on

I'm just wondering who all the OP is brewing two barrel batches for.

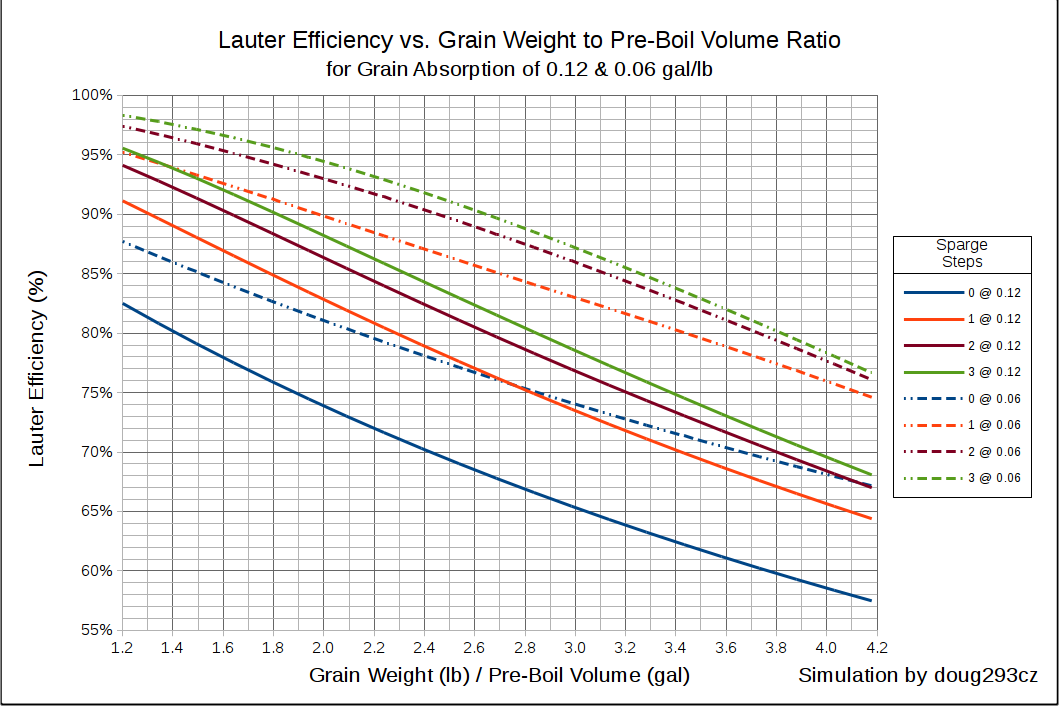

I did not say there was a "problem" with larger grain bills. I said that as the grain weight to pre-boil volume ratio increases, the lauter efficiency decreases. This is due to the fact that more grain retains a larger fraction of the total wort than does less grain (assuming the same grain absorption rate.) The chart below shows what happens to lauter efficiency as the grain weight to pre-boil volume changes, for two different grain absorption rates, and zero to three equal volume batch (or dunk) sparges:As long as there is at least 2.5 times more water than grain (2.5 liters of water per kilogram of grain), there are no problems with efficiency

Using the grain weight to pre-boil volume ratio makes this chart batch size independent.

Brew on

The end product might not be beer...I'm just wondering who all the OP is brewing two barrel batches for.

Brew on

I did not say there was a "problem" with larger grain bills. I said that as the grain weight to pre-boil volume ratio increases, the lauter efficiency decreases. This is due to the fact that more grain retains a larger fraction of the total wort than does less grain (assuming the same grain absorption rate.) The chart below shows what happens to lauter efficiency as the grain weight to pre-boil volume changes, for two different grain absorption rates, and zero to three equal volume batch (or dunk) sparges:

View attachment 869923

Using the grain weight to pre-boil volume ratio makes this chart batch size independent.

Brew on

I've seen that chart before, but my measured OG matches the calculation. I use BrewMate and instead of 23L (6 gallons for 5 gallons of bottled beer) I calculate as if my batch size is 46L plus 8L of water loss (remains in the grain and evaporates during the boil). My mash efficiency is 70%, which is about 5% less than when brewing two batches. For me, an acceptable loss considering the time and energy saved.

DuncB

Well-Known Member

I love this chart would a conversion to metric be easy ?I did not say there was a "problem" with larger grain bills. I said that as the grain weight to pre-boil volume ratio increases, the lauter efficiency decreases. This is due to the fact that more grain retains a larger fraction of the total wort than does less grain (assuming the same grain absorption rate.) The chart below shows what happens to lauter efficiency as the grain weight to pre-boil volume changes, for two different grain absorption rates, and zero to three equal volume batch (or dunk) sparges:

View attachment 869923

Using the grain weight to pre-boil volume ratio makes this chart batch size independent.

Brew on

Thanks for the info. I was concerned about the bags weight capability. I have a chain fall to do the heavy lifting. Without using the conical as a kettle the biggest pot I have available is 20 gallons so lifting the bag won't be an issue. I really appreciate the insight on the easley overlooked details that bite you in the butt the day you try to incorporate shenanigans into the real world.Yes, for more than a five gallon batch, you need some kind of pulley system (unless you are a serious weightlifter.) A hoist is nice if you like toys and have the funds. Many of us use pulleys even for 5 gal batches. You don't necessarily need a "crane", just something to hang the pulley from. Ceiling joists work well, as do tall step ladders, deer hanging tripods, engine hoists - there are lots of possibilities.

The bag does not need any special "strong material" the bag for the 145 gal (280+ lb grain bill) is made out of the same material as the smaller bags that Wilser makes. The material is much stronger than it looks.

Brew on

I'm just wondering who all the OP is brewing two barrel batches for.

2 60 liter kegs per month, one for me and one for a buddy who's footing a good chunk of the equipment bill.I'm just wondering who all the OP is brewing two barrel batches for.

Oh sorry forgot to mention that If not brewing in the unitanks one will be sold. The wife is starting to ask questions.2 60 liter kegs per month, one for me and one for a buddy who's footing a good chunk of the equipment bill.

The chart is primarily for illustrative purposes, as it only applies to a limited set of parameters. My spreadsheet, that was used to create the chart, allows the parameters to be set to your specifics, and works in imperial (gal & lb) or metric (liters & kg.) To use the spreadsheet, download a copy either as an Excel or LibreOffice spreadsheet.I love this chart would a conversion to metric be easy ?

Brew on

DuncB

Well-Known Member

@doug293cz

Great I've got the spreadsheet I'll play with that again.

Great I've got the spreadsheet I'll play with that again.

Similar threads

- Replies

- 1

- Views

- 2K

- Replies

- 4

- Views

- 587

- Replies

- 1

- Views

- 481

Latest posts

-

-

-

-

-

-

-

Barleywine natural conditioning failed, switched to force carb, but now what? 😆

- Latest: BrewnWKopperKat