Other Half have contributed a double recipe to the

https://alltogether.beer/ relief initiative - brew it either with 10 IBU, 1318 and <300ppm Cl NEIPA style or 50 IBU, Chico and <150ppm sulphate for a West Coast version. Obviously they're not going to give away all their secrets, and it's designed to be fairly accessible for brewers and consumers alike, but it gives you an idea of how they think :

ALL TOGETHER Recipe by Other Half Brewing

[email protected]

This homebrew version of our ALL TOGETHER recipe is designed for 5 gallons. You know your system best, adjust for your own efficiency.

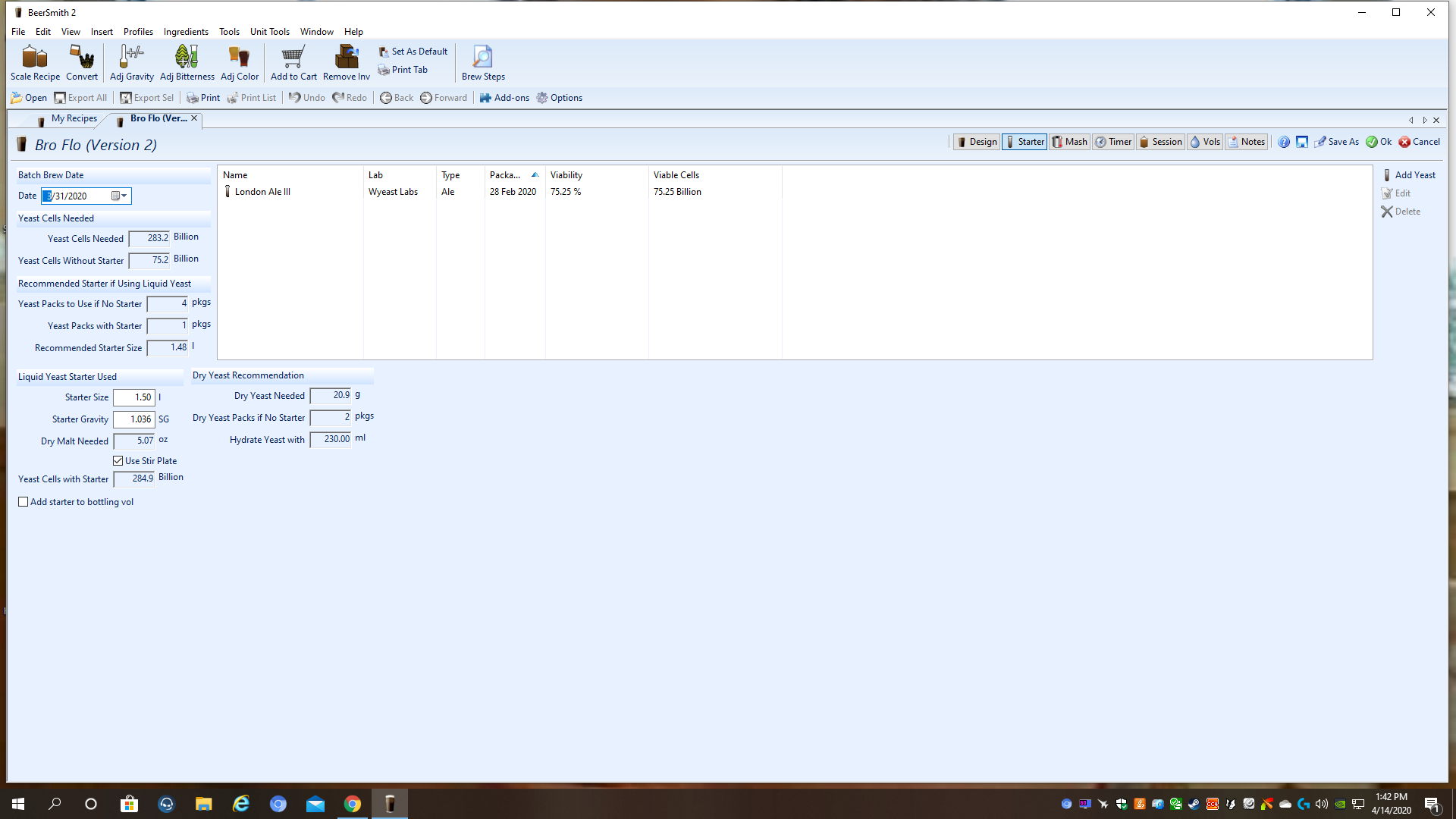

Yeast: London Ale (NEIPA) or Chico (WCIPA)

OG 16P or 1.064 SG

FG 3.2P or 1.013 SG

Mash Temp. 154F

In Brooklyn we have a very soft, neutral water profile. For NEIPA we recommend calcium chloride additions and we aim to stay under 300ppm chloride. For WCIPA we recommend calcium sulfate and we aim to stay around 150ppm or less. You know your water best so adjust accordingly.

Grain Bill:

2-row: 10.5 lbs

Flaked Oats: 1.5 lbs

Briess Carapils: .5 lbs

Hop Schedule:

Columbus (or bittering hop of your choice) to 10 ibu @ 60 Min (NEIPA) or to 50 ibu @ 60 min (WCIPA)

Mosaic 2 oz @ Whirlpool

Cascade 1 oz @ Whirlpool

Simcoe 2 oz @ Dry Hop

Citra 2 oz @ Dry Hop

Mosaic 4 oz @ Dry Hop

Cascade 2 oz @ Dry Hop

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

At least these are cheaper hops...

At least these are cheaper hops...