cheesebach

Well-Known Member

- Joined

- Jun 27, 2014

- Messages

- 305

- Reaction score

- 86

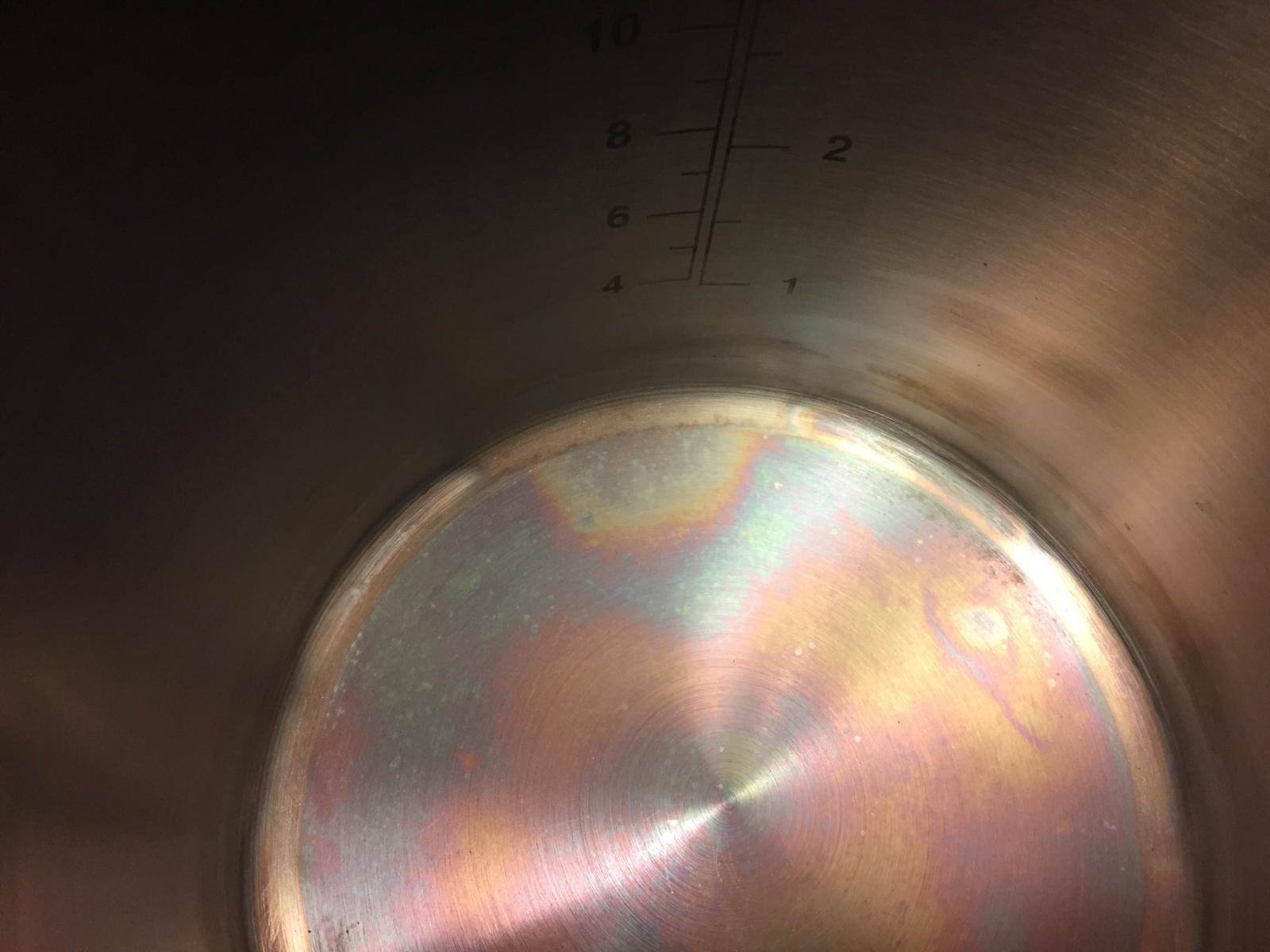

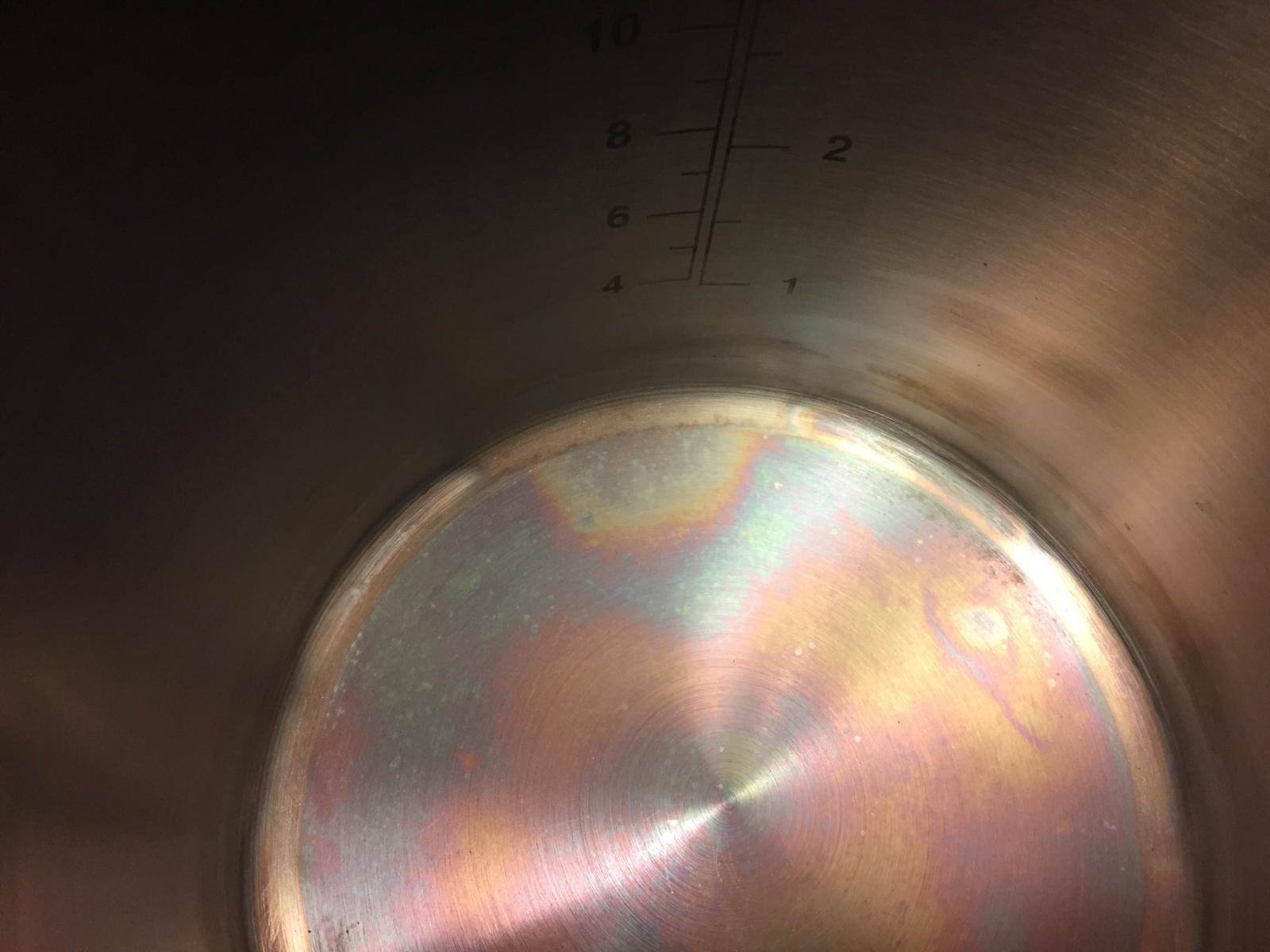

This may just be the OCD in me, but does everyone get the blue or rainbow colored stains at the bottom of their stainless brew kettle after each brew session? Attached is a photo of my new 6 gallon kettle after my first brew session with it. I've had the same thing with my 10 gallon megapot that I've been using for the past 2 years after every brew with it as well. You can see from the photo, that it basically looks like an oil slick which I'm assuming is from some kind of oxides forming on the surface. These are easily removed with some BKF, but it doesn't seem like I should need to be doing this after every brew, and I'm wondering if anything is getting into my beer while these oxides or whatever are forming during the boil.

After doing some searching to find the cause of why this is happening, I'm still coming up empty. The most common explanation I've read is overheating, which doesn't make sense to me since I get it on the inside of my kettle which is covered by a few gallons of boiling wort so I can't imagine that it would be getting much over boiling temp. Also, it's clearly a surface thing since the BKF removes it with little effort. The other thing I've read is that it's due to lack of passivation, but I've tried everything available to me to try to passivate the kettle and it still comes out looking like this after the brew - BKF, citric acid, star san at 1oz per gallon, makes no difference.

Does everyone with a stainless kettle get this, or is this an issue with my kettle or process? Any ideas are much appreciated.

After doing some searching to find the cause of why this is happening, I'm still coming up empty. The most common explanation I've read is overheating, which doesn't make sense to me since I get it on the inside of my kettle which is covered by a few gallons of boiling wort so I can't imagine that it would be getting much over boiling temp. Also, it's clearly a surface thing since the BKF removes it with little effort. The other thing I've read is that it's due to lack of passivation, but I've tried everything available to me to try to passivate the kettle and it still comes out looking like this after the brew - BKF, citric acid, star san at 1oz per gallon, makes no difference.

Does everyone with a stainless kettle get this, or is this an issue with my kettle or process? Any ideas are much appreciated.