FriendOfBrewers

Member

- Joined

- Aug 1, 2014

- Messages

- 24

- Reaction score

- 2

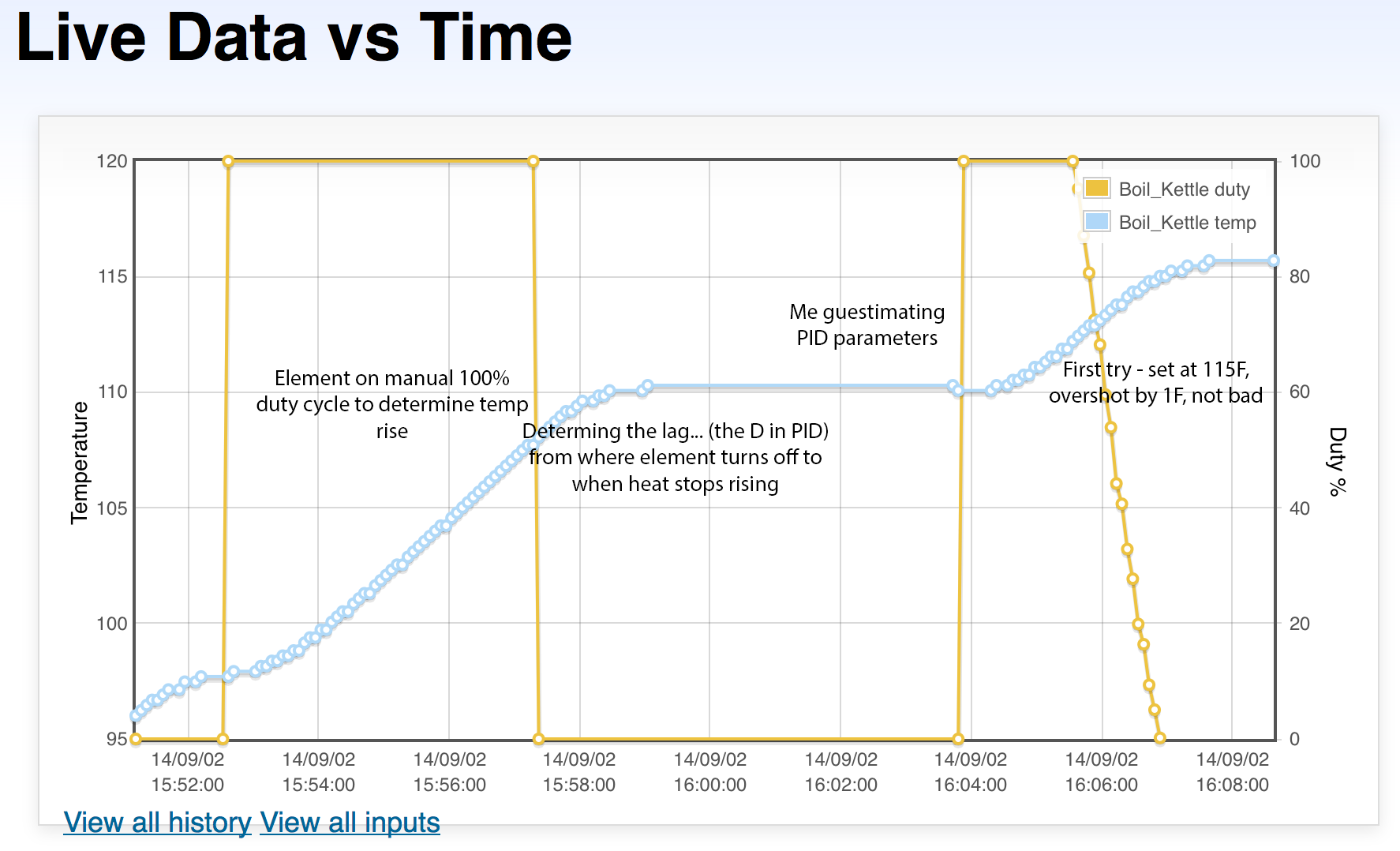

Here's some notes on my attempt to tune the PID.

With the pump at full speed, I got closest to my set temp, 153 F, with P=65, I=1, D=0.

It makes sense now that I think about it, but I was really surprised when I slowed the pump to see how much these same settings caused oscillation. The temperature would repeat a cycle of overshooting the set point by a couple degrees and then falling a couple of degrees below the set point. I could reduce this my changing P to something around 25. Ultimately this shouldn't matter, my 12v DC pump can move about 3gpm so I should be able to run it at full speed the entire mash.

With the pump at full speed, I got closest to my set temp, 153 F, with P=65, I=1, D=0.

It makes sense now that I think about it, but I was really surprised when I slowed the pump to see how much these same settings caused oscillation. The temperature would repeat a cycle of overshooting the set point by a couple degrees and then falling a couple of degrees below the set point. I could reduce this my changing P to something around 25. Ultimately this shouldn't matter, my 12v DC pump can move about 3gpm so I should be able to run it at full speed the entire mash.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)