Willee

Well-Known Member

I dont know ... I really enjoy seeing the yeast churn with a clear plastic fermenter.

That looks awesome, but I have a couple of concerns.

#1 you are using PBW right? Is that going to eat your pond powerhead?

#2 how much better the sprayball and loop than just filling the thing up and letting it soak?

Or turn the pick-up down into this stainless scrubber.... You'd need to do this before adding your wort.

I use one on my keggle pick-up when I whole hop.

I also shove these into outboard prop exhaust to keep the mice out of the motor when I winterize the boat. Meeces don't like chewing on stainless steel.

[emoji4]

View attachment 578634

with some Tetris-level creative arranging, i can just fit 2 buckets in my kegerator. one is on the "floor" of the fridge while the other is on the hump so they're vertically offset. i need to use some wood blocks to support the other side of the bucket riding the hump. my kegerator is a standard upright, freezer-on-top fridge. i'll post a pic next time i have this set up, likely in about 2 or 3 weeks (brewing this weekend, i use this setup to cold-crash two buckets at once).Do these fit in the beverage refrigerators that some people use for fermentation temp control?

other than the scrubbie/filter idea, have you been rotating the racking arm?Has anyone had any luck doing pressure transfers with a large dry hop bill? 8oz+?

With my first batch, I had 2oz of dry hops. I cold crashed for 48 hours to 36 degrees, and the valve clogged after about half of the batch was transferred. It was an open transfer and I only had the valve open half way. I assumed the barb was standard 1/2" and would fit a 1/2" hose with no need for a clamp, but I was wrong. I needed to dial back the valve to avoid sucking in air. I fixed this for my second batch and was able to open the valve 100% during transfer.

So again... if I want to brew a NEIPA with an 8oz dry hop bill... what should I do to avoid problems during transfer?

If you're transferring from a fermenter with a spigot, you can attach a hose from the spigot to the liquid out post. That presents two problems. First, assuming you've purged the serving keg with co2, you've got positive pressure in there and the beer won't flow. Second, as the beer leaves the fermenter, air fills the headspace, potentially oxidizing the beer. If you look at Kingmatt's picture, he solves #1 by venting the keg, and #2 by sending CO2 from the tank into the fermenter headspace.

question for the folks who do this non-pressurized, closed-loop transfer: do y'all have any problems starting the flow? is there a trick about how much pressure should be in the keg, or what order to hook things up? something else?What I propose is that you take Kingmatt's setup, but remove the CO2 tank and instead connect that gas line to the gas post on the keg. Now when you open the valve on the fermenter, the beer will flow into the keg via gravity, and the gas in the keg will flow into the fermenter headspace.

The benefits I've found are that I (1) save some co2; (2) don't have to monitor the pressure in the fermenter that's not rated for pressure; (3) simplicity--one less piece to deal with (the co2 tank).

another question about transferring: does anyone have a good way of knowing what the level of the liquid inside the bucket is?

when doing closed transfers, i can't see how much beer is left. I only want to turn the pickup as far down as necessary so would be useful to know where the top of the beer is.

there must be similar solutions for knowing how much beer is left inside a keg? maybe something with a floating magnet inside the keg and an magnetically-held indicator on the outside?

weight is an interesting idea, something along the lines of "buckets weighs 5.5 pounds when there are 2 inches of beer and trub left" (those numbers are completely made up). not quite as good as a real-time reading of what the liquid level is, but certainly better than no info.If post cold crash, you could use exterior condensation as a gauge. Maybe weight if you have the right scale.

another question about transferring: does anyone have a good way of knowing what the level of the liquid inside the bucket is?

when doing closed transfers, i can't see how much beer is left. I only want to turn the pickup as far down as necessary so would be useful to know where the top of the beer is.

there must be similar solutions for knowing how much beer is left inside a keg? maybe something with a floating magnet inside the keg and an magnetically-held indicator on the outside?

I love my 7.5gal fermenter. I really feel it has helped me brew better hoppy beers, especially NEIPAs, by being able to close transfer to a keg with no oxygen pickup.

Below is a pic of how I avoid oxygen pickup through my airlock when transferring to my keg. The output hose on my C02 tank fits perfectly into the top of my airlock so I set my regulator as low as it will go and let it run for the entire transfer. The c02 isn't pushing the beer to the keg (it is gravity fed) it is just getting sucked in by the displaced beer. Works like a charm!View attachment 570013

Edit: Can't delete so I'll leave this but it looks like you must have this guy

http://shop.greatfermentations.com/...MI_Z-1qtG43AIVzlYNCh0o-wlhEAQYBCABEgKA0PD_BwE

looks like I'll be ordering one!

i managed to frankenstein myself a connection set-up, i'll post pix tonight... no fancy parts required, i just used hoses and parts i had sitting around.How did you get from anvil spigot to beer disconnect? It looks like you have a different barb than I do. I just got a 1/2" to 1/4" barb reducer to help me a little but feel like there's got to be a better way than hose from the anvil to the reducer then another hose from reducer to beer line and it looks like you have it.

Edit: Can't delete so I'll leave this but it looks like you must have this guy

http://shop.greatfermentations.com/...MI_Z-1qtG43AIVzlYNCh0o-wlhEAQYBCABEgKA0PD_BwE

looks like I'll be ordering one!

how much pressure depends on how rushed i am. if in a hurry, i'll crank up the pressure pretty high (like 10-15 psi) at first then ease back - don't need 10 psi the whole time. but generally i go pretty low, 2-4 psi, and just wait it out. it's not like i don't have 1,001 things to clean and sanitize while i wait...When purging your keg (I filled with star-san then pushed it all out with c02) How much pressure are you doing that with? and do you leave the tank on the whole time or do you shut off and on as needed? and if different than above, how much pressure would you say you have in the keg when it's time to transfer beer?

depends how full of sanitizer the keg is. if it's full to the very top, can't possibly fit a drop more, then no - not much use in purging.Using the method above, is it still necessary to purge the headspace in the keg after filling? I don't really see why it would be but I'm no expert.

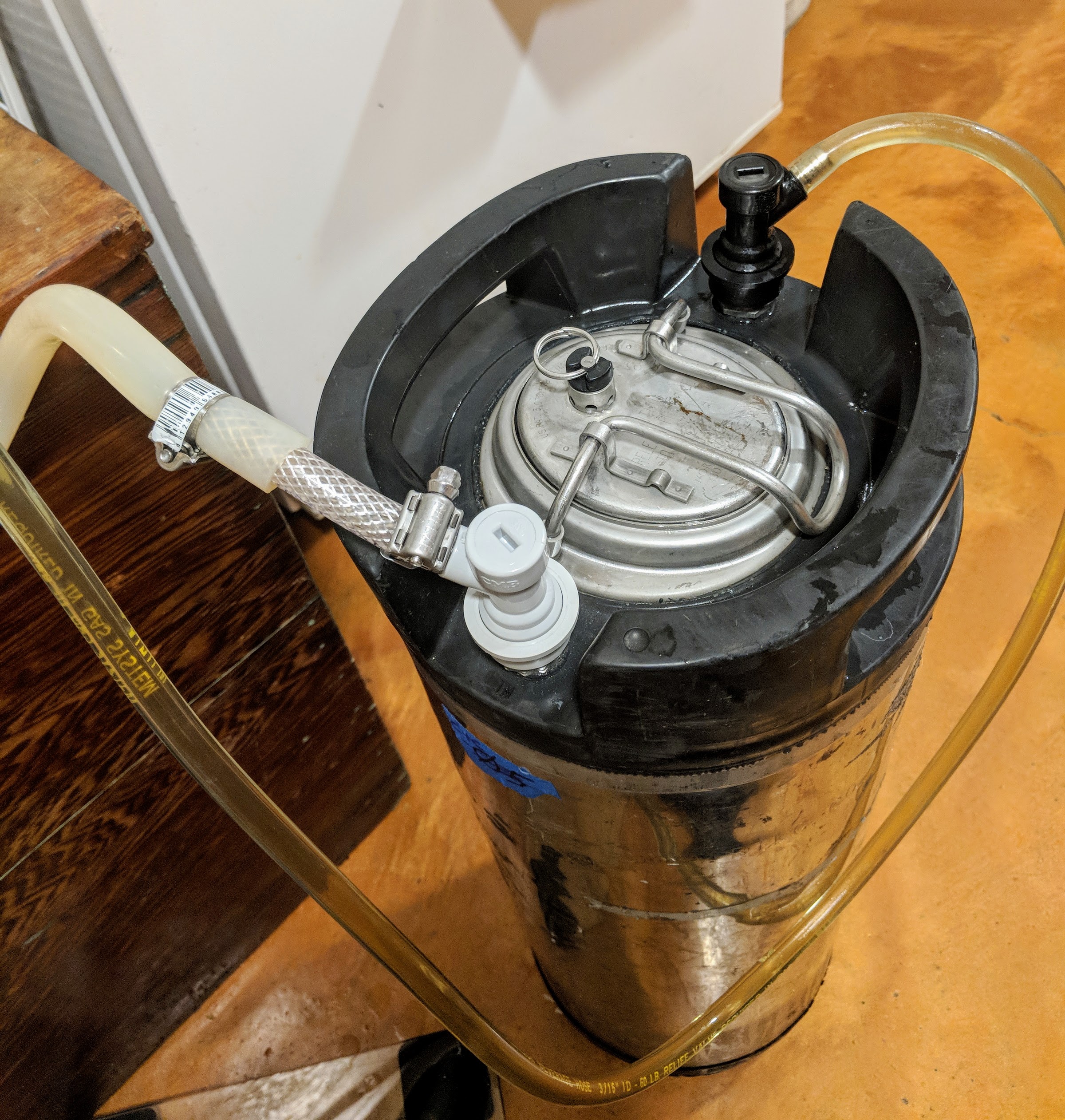

see attached pix. file under "better late than never"...i managed to frankenstein myself a connection set-up, i'll post pix tonight... no fancy parts required, i just used hoses and parts i had sitting around.

in case anyone cares, you can see my kegerator in the first pic above. unfortunately i forgot to take a pic when the buckets were inside the fridge. next time...with some Tetris-level creative arranging, i can just fit 2 buckets in my kegerator. one is on the "floor" of the fridge while the other is on the hump so they're vertically offset. i need to use some wood blocks to support the other side of the bucket riding the hump. my kegerator is a standard upright, freezer-on-top fridge. i'll post a pic next time i have this set up, likely in about 2 or 3 weeks (brewing this weekend, i use this setup to cold-crash two buckets at once).

i'm still looking for any insights on how to successfully and consistently get a closed transfer started.question for the folks who do this non-pressurized, closed-loop transfer: do y'all have any problems starting the flow? is there a trick about how much pressure should be in the keg, or what order to hook things up? something else?

on my last batch I tried the closed-loop thing and I had problems getting the transfer to start. worked perfectly once I got flowing, but on one of my 3 buckets I gave up completely and ended up transferring with an auto-syphon.

i'm still looking for any insights on how to successfully and consistently get a closed transfer started.

a few nights ago i transferred 2 buckets, and everything went great with the saison but i completely failed on the IPA (dammit). after struggling with the damn thing for 15 mintues, i ended up just using a straight hose into the open keg... i.e. an open transfer. t'was very, very frustrating.

thank you for your insights, i'm going to try that order next time i transfer.I've only done the one and maybe I got lucky but I'm pretty sure after my hoses were all ready, I did the following.

1. Connected one end of my gas line to the keg, left the other disconnected but it had a disconnect on it so the line was sealed off. With your setup, you probably have to do gas line to the fermenter airlock first, leaving the keg side disconnected.

2. Hooked my beer line up to the fermenter and then to the keg.

3. Opened the ball valve on fermenter.

4. Hooked the gas line up to the fermenter quickly (not sure if speed really mattered). And with your setup this is where you'd connect the gas line to the keg instead.

Started right up. Are you making sure the dip tube is turned enough so it's out of the trub? Maybe that's giving you problems.

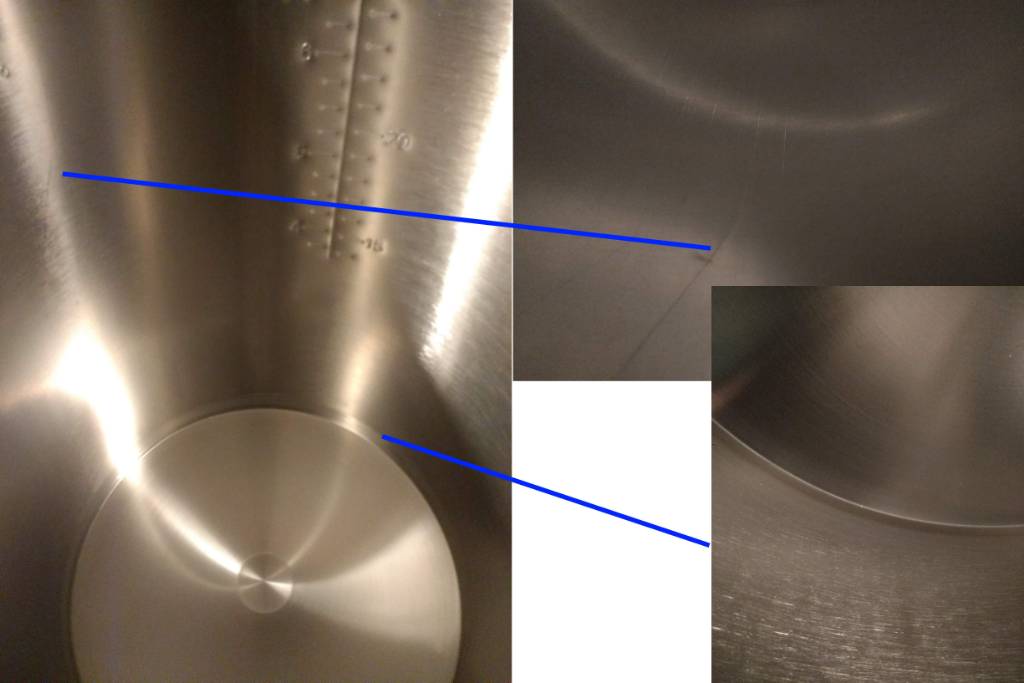

I got mine last night, ordered it July 1st... Unfortunately I'm seeing issues similar to Roman. Some vertical scratches on the inside, and a ring of scratches near the base. I sent in a ticket last night, hopefully I can get this resolved soon. Anyone else seen anything like this? I'm wondering if this is a side effect of attaching the base.Has anyone that pre-ordered one in June receive them yet?

It's pretty easy to feel. Most the bucket isn't terribly polished to begin with, but this is a pretty dramatic difference.I just got notice they finally shipped. hoping for the best. are those scratches something you can feel or lighter marks. I dunno, definitely don't want to see any of that tomorrow

If your line is getting clogged, it may help to take the insides out of the QD on the keg.i'm still looking for any insights on how to successfully and consistently get a closed transfer started.

a few nights ago i transferred 2 buckets, and everything went great with the saison but i completely failed on the IPA (dammit). after struggling with the damn thing for 15 mintues, i ended up just using a straight hose into the open keg... i.e. an open transfer. t'was very, very frustrating.

I got mine last night, ordered it July 1st... Unfortunately I'm seeing issues similar to Roman. Some vertical scratches on the inside, and a ring of scratches near the base. I sent in a ticket last night, hopefully I can get this resolved soon. Anyone else seen anything like this? I'm wondering if this is a side effect of attaching the base.

I'm not sure if it's something I could buff out, but I feel like I shouldn't have to. Kind of feeling like I should have spent the extra money for the SS brewtech, the finish on that is much better. I'm not a fan of the racking cane o-ring design on that one, but not a lot of options out there right now.View attachment 584660