ebstauffer

Well-Known Member

If the house is designed to have 3 wire 220v, is it likely that a neutral even exists?

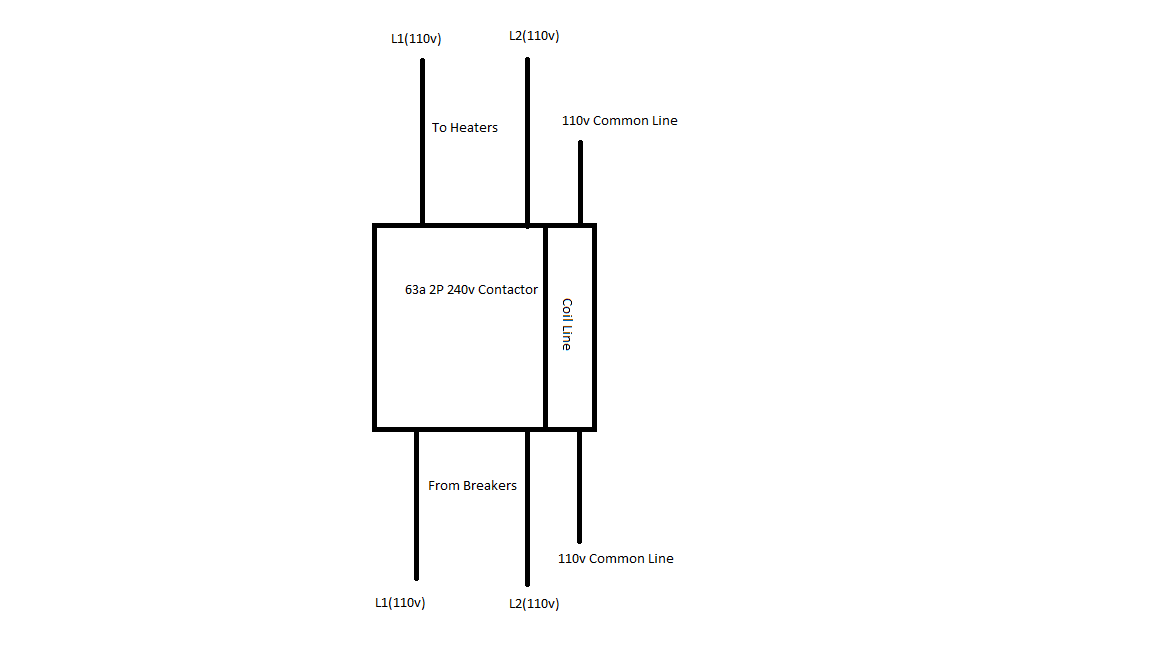

The ground doesn't come into your house from the pole, the neutral does. The ground is from, well, the ground. Typically from two places at least 6' apart. One is normally a grounding rod, the other (at least my circa 1930s home) is a #6 bare copper wire clamped to the metal water line coming into the house. Go out and look at your weatherhead. The neutral is the bare wire, the other two are the hot legs. You'll have 120 v across the neutral and either hot leg and 240 across the two hot legs. Please be careful.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)