EyeofdaHawk

Well-Known Member

Howdy all

In preparation for a SS fermentor, ideally with jacketed cooling sleeve, i'm building a glycol cooler (as a new one, plus the SS fermenter is cost prohibitive).

I've picked up a portable air con, roughly 4kw capacity. I would have gone for a window one as it would have probably been easier to build with, but they're not that common here in Aus, compared to the portable ones (which renters frequently have).

I've removed all the external covering to expose the coils, and compressor etc.

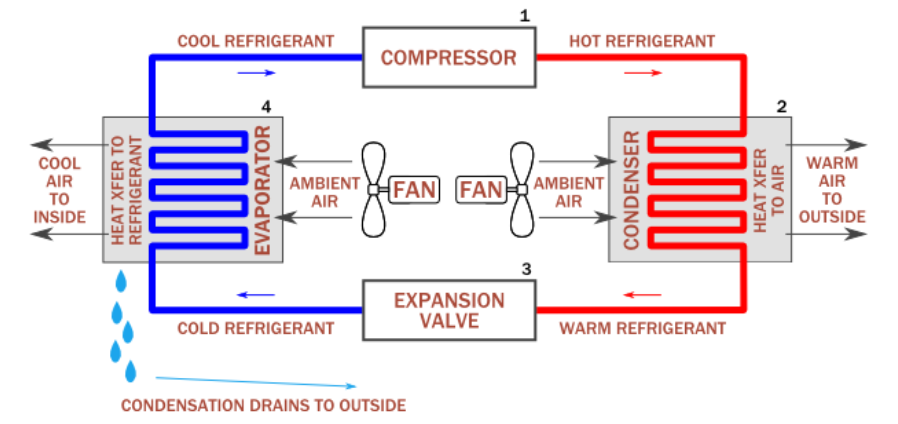

Now i have several questions i'm hoping the community can assist with. The cold coils are on top, and the hot on bottom.

It appears there may be some valve connecting the hot/cold coils, not sure if this will have an impact.

Either way, it appears the coil i'll need to bend (last pic) should be work-able, although maybe a bit tricky. I've not been able to find any advice on the net, or via Youtube, about how to actually bend it, other than 'carefully' as it will be ruined if i break the coil. Any suggestions?

Finally, there is a surprising amount of electronics. Not really sure to do with most of this. Any suggestions?

Appreciate if i look out of my depth, which i probably am, but always keen to learn.

Thanks for your advice

Hawk

In preparation for a SS fermentor, ideally with jacketed cooling sleeve, i'm building a glycol cooler (as a new one, plus the SS fermenter is cost prohibitive).

I've picked up a portable air con, roughly 4kw capacity. I would have gone for a window one as it would have probably been easier to build with, but they're not that common here in Aus, compared to the portable ones (which renters frequently have).

I've removed all the external covering to expose the coils, and compressor etc.

Now i have several questions i'm hoping the community can assist with. The cold coils are on top, and the hot on bottom.

It appears there may be some valve connecting the hot/cold coils, not sure if this will have an impact.

Either way, it appears the coil i'll need to bend (last pic) should be work-able, although maybe a bit tricky. I've not been able to find any advice on the net, or via Youtube, about how to actually bend it, other than 'carefully' as it will be ruined if i break the coil. Any suggestions?

Finally, there is a surprising amount of electronics. Not really sure to do with most of this. Any suggestions?

Appreciate if i look out of my depth, which i probably am, but always keen to learn.

Thanks for your advice

Hawk