You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

NE Style IPA, too tough for a beginner?

- Thread starter marjen

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Timing is tight how? Should I leave it on stir played longer? Like say Saturday morning, then refrigerate?

Yeast don't know how to tell time and don't know what day it is, they just do their thing. So, any guidelines on timing of starters is just that: guidelines. That said, sticking to some best practices will help you make the best beer you can.

Here's what I would do in your current situation:

thursday evening: make the starter and put it on the stir plate

friday evening or saturday morning: take it off the stir plate and put it in the refrigerator

Sunday when you start brewing: carefully decant the starter beer off of the top and let the yeast warm to room temperature

That may not quite be ideal (like i said, you can't tell the yeast what time and day they're making beer and tell them to get ready), but it's damn close.

Why might it not be ideal? There's lots of variables here. Some yeast ferment faster than others and will ideally have more or less than a day to multiply in the starter. That will also change with how big the starter is and what temperature it's fermenting at. Some highly flocculent yeast will be fine with a much shorter cold crash. Pay attention to how the starter looks for your first several batches and you'll know exactly what to look for in the future.

Also, Kudos to you for jumping right into the deep end here and following through on the plan for your first brew!

Also, Kudos to you for jumping right into the deep end here and following through on the plan for your first brew!

Thanks. I will not be deterred. �� Too make it more complicated I am going to split the wort in two to try two different yeast strains. And it looks like it's only going to be about 35 degrees out on Sunday. Was supposed to be a lot warmer.

Alright making the starter tonight. I am about to officially be a brewer.

Ok so I just got done making my starter.  Everything was going great until I started second guessing my directions.

Everything was going great until I started second guessing my directions.

I have a 2L flask. I had the starter with 2 cups of water and 1/2 cup of DME. got through boil, stirred it in, poured it in the flask and it looked like nothing. So i started frantically searching the web and got about 500 different answers on how much water and DME to use. So tried doubling it and mixing together which turned into a mess as I stepped away for 2 seconds to read more and it started overflowing. So finally I dumped that and started over with my original 2 cups water to 1/2 cup DME. I then pitched in the yeast once it was at about 75 degrees and it is now on my stirstarter. I am using WL 007 which actually says it does not need a starter. It also was weird as I thought it was liquid yeast, but said dry on package so I did not smack it. But when I poured it out there was liquid in there and then some clumps. I agitated it real good before starting the stirstater and now it looks like it is all mixed in good.

So finally I dumped that and started over with my original 2 cups water to 1/2 cup DME. I then pitched in the yeast once it was at about 75 degrees and it is now on my stirstarter. I am using WL 007 which actually says it does not need a starter. It also was weird as I thought it was liquid yeast, but said dry on package so I did not smack it. But when I poured it out there was liquid in there and then some clumps. I agitated it real good before starting the stirstater and now it looks like it is all mixed in good.

So did I completely screw it up? Did I make the right amount?

At the very least I got my feet wet. I think I did a good job with the cleaning and sanitation piece. And if I did not second guess what I was doing it would have been great.

I have a 2L flask. I had the starter with 2 cups of water and 1/2 cup of DME. got through boil, stirred it in, poured it in the flask and it looked like nothing. So i started frantically searching the web and got about 500 different answers on how much water and DME to use. So tried doubling it and mixing together which turned into a mess as I stepped away for 2 seconds to read more and it started overflowing.

So did I completely screw it up? Did I make the right amount?

At the very least I got my feet wet. I think I did a good job with the cleaning and sanitation piece. And if I did not second guess what I was doing it would have been great.

Ok so I just got done making my starter.Everything was going great until I started second guessing my directions.

I have a 2L flask. I had the starter with 2 cups of water and 1/2 cup of DME. got through boil, stirred it in, poured it in the flask and it looked like nothing. So i started frantically searching the web and got about 500 different answers on how much water and DME to use. So tried doubling it and mixing together which turned into a mess as I stepped away for 2 seconds to read more and it started overflowing.So finally I dumped that and started over with my original 2 cups water to 1/2 cup DME. I then pitched in the yeast once it was at about 75 degrees and it is now on my stirstarter. I am using WL 007 which actually says it does not need a starter. It also was weird as I thought it was liquid yeast, but said dry on package so I did not smack it. But when I poured it out there was liquid in there and then some clumps. I agitated it real good before starting the stirstater and now it looks like it is all mixed in good.

So did I completely screw it up? Did I make the right amount?

At the very least I got my feet wet. I think I did a good job with the cleaning and sanitation piece. And if I did not second guess what I was doing it would have been great.

You need to use a calculator to get an estimate of how big of a starter to make. I'm partial to http://yeastcalculator.com/ (I started hosting it when the original site went down) but there any many others.

That is a pretty small starter though. You could add more if you want, or just let it go. Yeast packaging typically says that it's good enough for a 5G batch of up to 1.050 or something, but the general consensus is that the packages don't provide very good guidance.

Which is better liquid or dry? And any brand recommendations? True beginner here so no idea what I am looking for. Thanks I appreciate the help.

Performance wise, they are identical. It's largely personal preference. I like dry personally, but used mostly liquid when I was working as a brewer.

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

Ok so I just got done making my starter.Everything was going great until I started second guessing my directions. [...]

Relax, have a beer.

Over the next 2 days, please reread all the suggestions that have been given, and write/copy them down in a logical way. You may even find 2 or 3 different ideas or suggestions for some topics. One maybe better than the others, or is simply a user's preference, no better or worse.

If something isn't clear, reread, do a search, or ask again.

Regarding your starter, I think it was made clear you need to make a 2 liter starter, not 2 cups. A 2 liter starter is made with 2 liters of water and 200 grams of DME, about a cup's worth. You really should weigh the DME to be more accurate, but in a pinch, a measuring cup will work fine.

WLP007 is called Dry English Ale, it's a liquid yeast, not dry. It's made by White Labs, and is not a smack pack. There's nothing to smack. However, massaging the sleeve before opening helps to bring the solids back into suspension, so it pours easier.

The whole content of that Pure Pitch pack should be added to the starter, under the motto: No yeast left behind!

Once you get a bit more used to handling yeast and wort in sanitary ways, after emptying it out you can add some (sterile) wort to the sleeve to "rinse" it out. Again, handling yeast and chilled wort in a sanitary fashion is paramount for clean, uninfected beer.

If I may take the liberty to speak for all of us: Good luck with your first brew session! We like success stories as well as some drama, they go hand in hand. Please keep us posted on how it went, and what you would do differently next time.

Here's the fundamentals from both sides. When I was brewing for a brewpub, I logged and measured every ounce of product used. I set timers for boils, chills, fermentations, etc. Everything was done with an eye towards being able to exactly replicate the results. I made great beer. When I brew on my own as a hobby, I measure virtually nothing. I have terrible temperature control. I get bored and cut my boil off at 50 minutes instead of 60. I make great beer that I could never replicate.

At the heart of it, they used to do this in caves. In a decade if brewing with my laissez-faire approach, I've had exactly one batch I had to dump. Relax, have fun, and learn.

At the heart of it, they used to do this in caves. In a decade if brewing with my laissez-faire approach, I've had exactly one batch I had to dump. Relax, have fun, and learn.

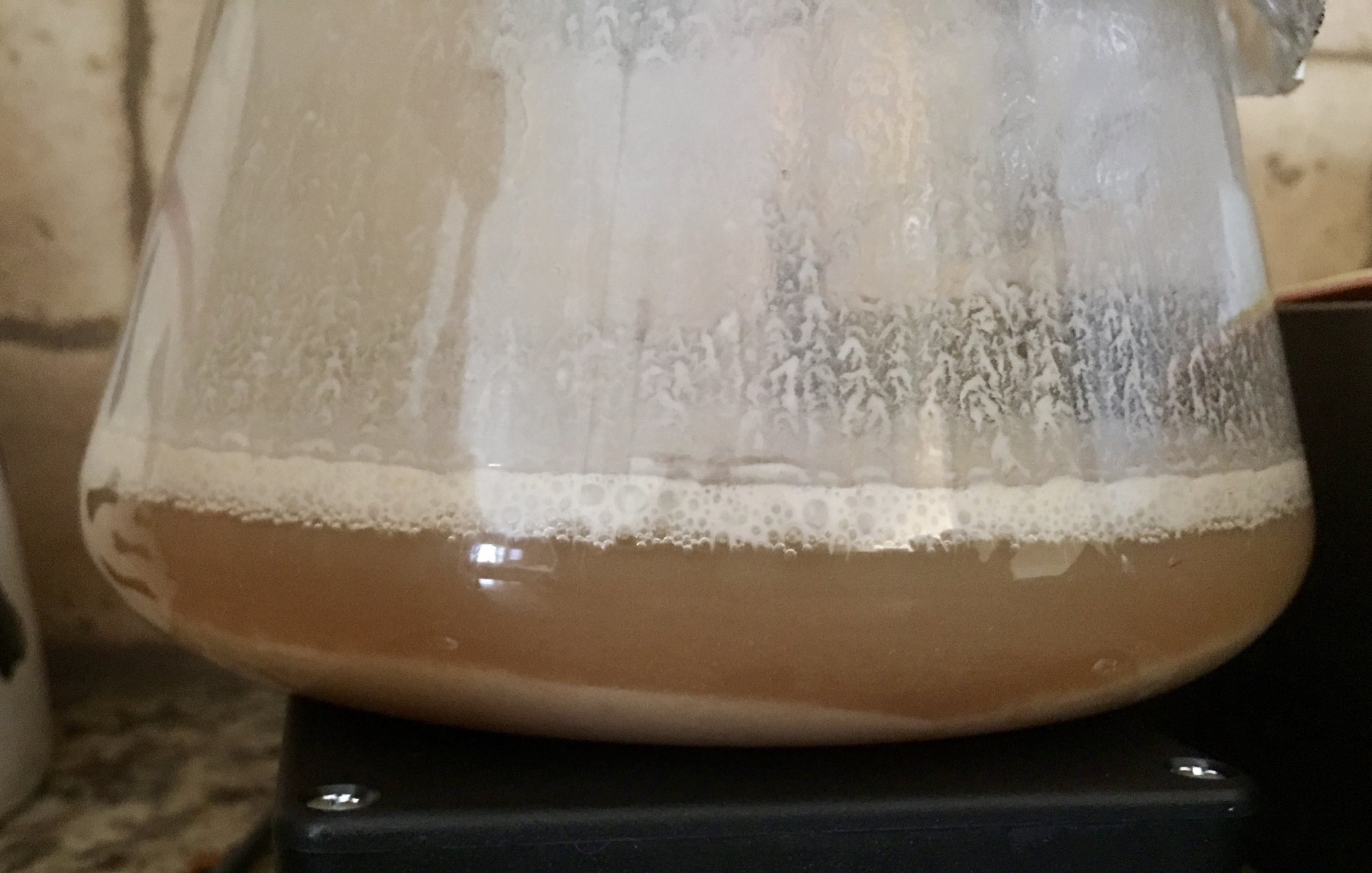

It's all good. Looks like the starter is doing well. Looking forward to my first brew day on Sunday. I am sure I will make some mistakes but it's part of the process.

Now since it's a small starter I probably won't really have to dump much if any water before I pitch the yeast Sunday I am assuming.

Tomorrow I am taking a NE IPA brewing class so should be good to get some more insight and tips prior to brew day. Appreciating all the help here, great forum.

Now since it's a small starter I probably won't really have to dump much if any water before I pitch the yeast Sunday I am assuming.

Tomorrow I am taking a NE IPA brewing class so should be good to get some more insight and tips prior to brew day. Appreciating all the help here, great forum.

McKnuckle

Well-Known Member

As a stickler for decanting, I would still pour off any obviously clear liquid - but you don't need to stress over adding ~500 mL (2 cups) of starter to your wort. It won't get noticed and will simplify your experience to ignore that step.

McKnuckle

Well-Known Member

^got it... no need to decant. Probably couldn't if you tried. Carry on!

^got it... no need to decant. Probably couldn't if you tried. Carry on!

Exactly, since this is the road you chose, there won't be anything to decant without losing yeast:

- Don't refrigerate

- Keep it stirring until ready to pitch on Sunday

- Pitch the whole shebang!

BeginnerBebeBrewer

Member

- Joined

- Oct 30, 2016

- Messages

- 22

- Reaction score

- 2

When I've brewed NE IPA I've found that the yeast is very vigorous and often cause alot of blow off over the first couple of days of primary fermentation. Don't panic! Therefore when your in the primary fermentor I would recommend using a blow off tube rather than the airlock device. Don't be alarmed if bits and flakes get in the tube just make sure the end of the tube is dipped into a suitable sanitizer to prevent any bacteria or wild yeast entering the fermentor. I dip the end of the tube into a little cup of starsan.

Brew day in progress! It's effing cold out so have a fire going in the firepit to keep warm. Some issues getting the burner going with the wind! But made a barricade around it and all was well. Currently in my boil, first hops added just waiting for the next one. This is fun!

taking forever to cool the wort!! I used a chiller but it was still taking time so i removed it. It is only like 30 degrees outside. The wort is sitting out there for like an hour and its still at like 90 degrees. I tried stirring it, did not really help. after the hot side going well, hoping this does not kill the batch.

I had already sanitized the fermenter, feel like i need to do it again as its been forever now.

I had already sanitized the fermenter, feel like i need to do it again as its been forever now.

Tombstone0

Well-Known Member

Stir your wort while it's chilling, it'll chill much faster. Depending on the size of your chiller and the temp of your water will effect the time, but mine usually chills in about 20-30 minutes.

So the brew day is over, I have cleaned everything up and have a chance to reflect out what has gone right and wrong.

Overall the hot side went very well. I was able to hit all my temps, remembered my hop additions and timers. Considering the cold and wind was still able to get up to boil and hold it fine.

The back side is where I am a little worried. I believe I did a good,job with cleaning and sanitizing. But once I prematurely pulled my chiller it took 90 minutes just to get down to about 75 degrees. And it was like 20 degrees outside so not sure what the issue was. So I got a little nervous and put it in the buckets. In one batch the little magnet thing from my starter end up in the fermenter, it's still there. The other bucket seems to have a bit of a leak on the airlock as bubbles are coming out of the base not the airlock itself. I tried taping it in to better seal it but not sure thT worked. So far the temp is still too warm. They are in a room that's about 65 and the temp on the buckets is about 74. Just moved to a oiler room to try and get the temp down.

So really next time I need to make sure I have some more is in the recirculating chiller cooler and next to get initial fermentation temps down. And figure out why the airlock is leaking. I don't have high hopes at this point for this batch but it was a start and I can't wait to get going again.

Overall the hot side went very well. I was able to hit all my temps, remembered my hop additions and timers. Considering the cold and wind was still able to get up to boil and hold it fine.

The back side is where I am a little worried. I believe I did a good,job with cleaning and sanitizing. But once I prematurely pulled my chiller it took 90 minutes just to get down to about 75 degrees. And it was like 20 degrees outside so not sure what the issue was. So I got a little nervous and put it in the buckets. In one batch the little magnet thing from my starter end up in the fermenter, it's still there. The other bucket seems to have a bit of a leak on the airlock as bubbles are coming out of the base not the airlock itself. I tried taping it in to better seal it but not sure thT worked. So far the temp is still too warm. They are in a room that's about 65 and the temp on the buckets is about 74. Just moved to a oiler room to try and get the temp down.

So really next time I need to make sure I have some more is in the recirculating chiller cooler and next to get initial fermentation temps down. And figure out why the airlock is leaking. I don't have high hopes at this point for this batch but it was a start and I can't wait to get going again.

I wouldn't worry about any of those things. It would definitely be good to get your fermentation temperatures down, but other than that it sounds like a successful first brew day. Congrats!

Superglue a small strong magnet on the outside of your starter flask. If you have this on facing down when you pitch your yeast, it will "catch" the stir bar. Make sure you put it at a spot you can knock the stir bars off with your finger to dislodge it for cleaning. When your done cleaning the flask and stir bar, put the stir bar back so you never loose it. Easy peasy.

Your chill time does seem really long. I made a homemade immersion chiller. 40' in the wort and a 20' pre-chiller I have coiled in ice and water. I get down to the 60s in under 30 mins.

Your chill time does seem really long. I made a homemade immersion chiller. 40' in the wort and a 20' pre-chiller I have coiled in ice and water. I get down to the 60s in under 30 mins.

McKnuckle

Well-Known Member

It would have been fine to just cover the buckets and let them sit outside for an hour or two, which would have gotten the temperature down handily. Brewers sometimes panic and rush to pitch yeast as soon as possible, all other factors be damned, and it's really not necessary as long as you follow common sense sanitation practices.

On the bright side, hopefully the wort will cool to room temperature while the yeast are in their growth phase.

On the bright side, hopefully the wort will cool to room temperature while the yeast are in their growth phase.

Temps are down today to about 66-68. Right where I want to be.

I also realized I blew the hop stand. Directions said 30 mins at 180. I realize I should have started there and let it cool but kept it steady at 180. Hopefully not to bitter as a result.

I also realized I blew the hop stand. Directions said 30 mins at 180. I realize I should have started there and let it cool but kept it steady at 180. Hopefully not to bitter as a result.

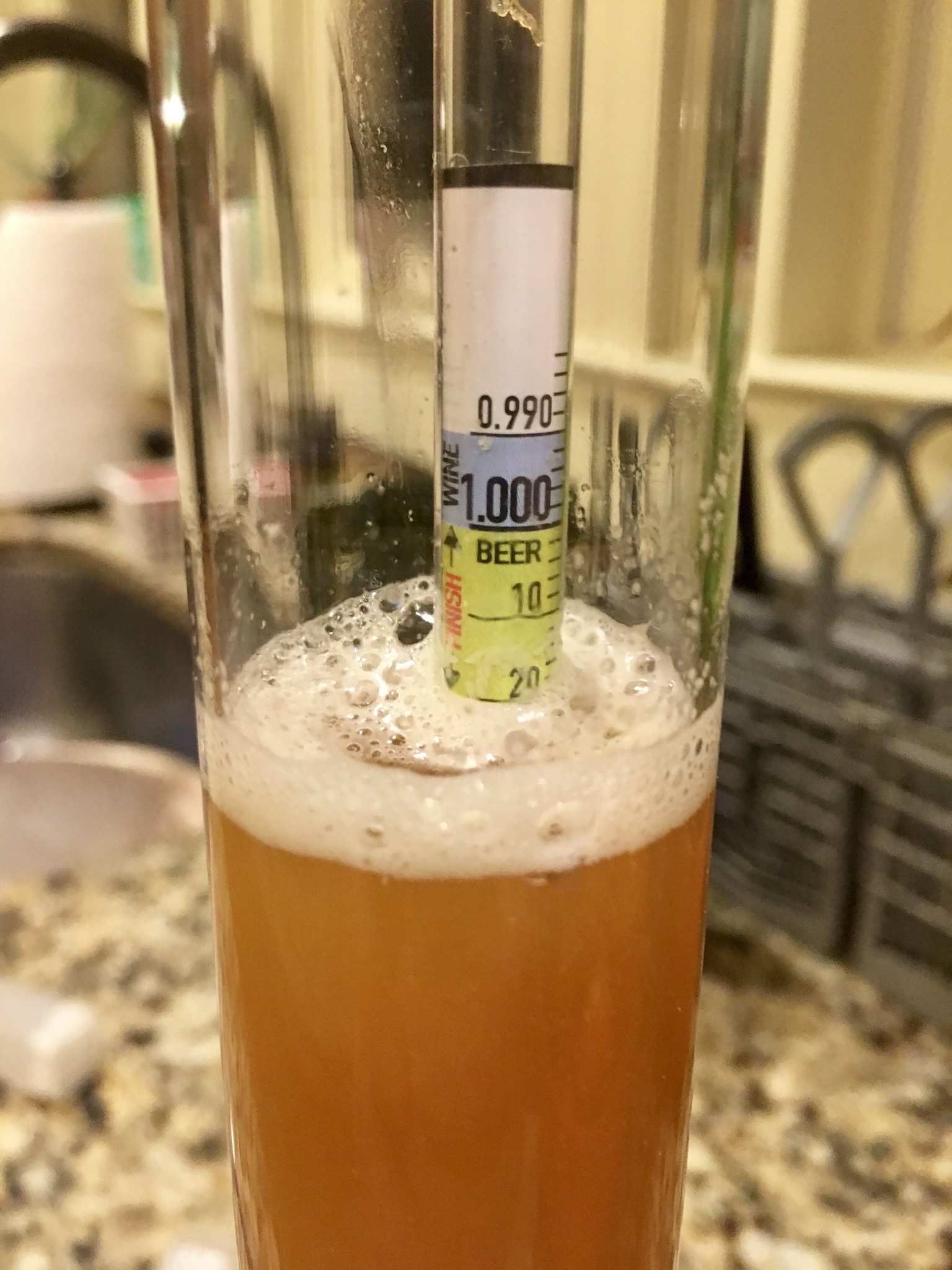

So I just took a gravity reading since my new hydrometer came in. Broke the original one so did not get an OG unfortunately.

The WLP007 is at 1.020

The WY1098 is at 1.026

This is over 48 hours in. I am planning on adding the dry hops Thursday night hopefully towards the tail end of fermentation. Then it will sit with the hops in the fermenter for 5 days. So Next Tuesday I will move it to the kegs. Temps are holding steady around 66-68 in the fermenters. SO far so good I think.

The WLP007 is at 1.020

The WY1098 is at 1.026

This is over 48 hours in. I am planning on adding the dry hops Thursday night hopefully towards the tail end of fermentation. Then it will sit with the hops in the fermenter for 5 days. So Next Tuesday I will move it to the kegs. Temps are holding steady around 66-68 in the fermenters. SO far so good I think.

So it's day 4 so I added my dry hops. Added 3 oz to both batches. Did one final reading and now,will let it sit for 5 days then it's off to the keg. Hated opening that bucket up and adding all that air but guess there is really no other way to do it. Looks like both batches are around 1.018 or 9. Final is supposed to be 1.017. I just ordered a Blichmann quick carb so I don't have to wait a couple weeks to try it  Patience is not one of my things. So will probably keg it Tuesday night, throw it in the keezer for a day and carbonate in on Wednesday. Going to be interesting, hope it's decent. Will probably brew another batch next weekend!

Patience is not one of my things. So will probably keg it Tuesday night, throw it in the keezer for a day and carbonate in on Wednesday. Going to be interesting, hope it's decent. Will probably brew another batch next weekend!

Also of note from when i added the dry hops yesterday, looks like the crud on top was now gone mostly. So a bunch on the sides and some spots on the top but it was not think at all. I am assuming this means it is mostly done fermenting? I have heard these yeast strains were fast, next time I will probably add the dry hops on day 3 while there is more activity going on.

The best (only) way to tell if fermentation is done is by taking gravity readings. Take one and see how it compares to the 1.017 you reported yesterday. Then do the same tomorrow.

I wouldn't try to rush the fermentation any more than you already are. I know it's common practice with NEIPAs to get that over the top hop flavor, but you should realize that you are knowingly doing something that can result in off-flavors, then covering up those off-flavors with a ton of hops.

Personally, I just let my beers go for several weeks.

I wouldn't try to rush the fermentation any more than you already are. I know it's common practice with NEIPAs to get that over the top hop flavor, but you should realize that you are knowingly doing something that can result in off-flavors, then covering up those off-flavors with a ton of hops.

Personally, I just let my beers go for several weeks.

I am probably not going to take another reading until Sunday then check again Tuesday. These types of beers seem to have a short life span and from what I have read kegging it about 8-12 days after pitching seems to be pretty normal. The recipe actually said to dry hop 4 days post pitch then keg 5 days later so I would be following the recipe with my current schedule. Final gravity for the recipe is supposed to be 1.016 so its pretty close. I will let it sit in the keg for a day or maybe two until I run the quick carb. So plan to try it out next Wednesday or Thursday.

Beer is in the kegs. Had some issues with one keg trying to do a closed transfer but used the fallback siphon method. Been force carving at 30 psi since yesterday afternoon will dial it back tonight. Probably sample tonight or tomorrow. Can't wait. It sure smells good.

SO a follow up. I forced carved the 2 kegs at 30 psi for 24 hours, then backed it down. I sampled the 2 kegs. The keg with the WL1098 actually is pretty decent. Low bitter, fairly smooth. Decent smell, but the taste itself is not quite there. Drinkable though. I had a pint last night and it was fairly enjoyable. Its in the ballpark of what I was going for.

The 2nd keg with the WLP007 I dont know what is up with it. Does not seem like it carbed quite right. There is some head but it tastes flat and just off. Not very appealing at all. Not drinkable. Not sure whats up with it. Going to leave it in the keg and see if it gets better. It honestly tastes stale or something really weird.

The 2 were made from the same wort, with the same hop additions. Only difference was yeast and different containers. I did have transfer issues with the WLP007 and it ended up bring open transfer and not sure if during that process something got contaminated as I had to play around with the keg, the connecters and hoses quite a bit to try and get the beer in the keg. Very different beers right now.

So I am planning on a brew day this weekend. I am going to try and fix the mistakes I made the first time around. I am planning another split batch. This time since the WL1098 tastes best will do half that and hold WL1318 as that is a very popular NE IPA strain. So will put those head to head to see what I like better.

The 2nd keg with the WLP007 I dont know what is up with it. Does not seem like it carbed quite right. There is some head but it tastes flat and just off. Not very appealing at all. Not drinkable. Not sure whats up with it. Going to leave it in the keg and see if it gets better. It honestly tastes stale or something really weird.

The 2 were made from the same wort, with the same hop additions. Only difference was yeast and different containers. I did have transfer issues with the WLP007 and it ended up bring open transfer and not sure if during that process something got contaminated as I had to play around with the keg, the connecters and hoses quite a bit to try and get the beer in the keg. Very different beers right now.

So I am planning on a brew day this weekend. I am going to try and fix the mistakes I made the first time around. I am planning another split batch. This time since the WL1098 tastes best will do half that and hold WL1318 as that is a very popular NE IPA strain. So will put those head to head to see what I like better.

I find that my NEIPAs taste pretty raw for a few weeks after I keg them. It takes some time for those hop particles to settle and the hop flavor to smooth out. Even a few weeks after kegging, if it didn't have a pour for a few days, I'd get a lot of hop material in the first pour. If you don't like the taste now, give it a few weeks at a normal carb psi and you might be surprised.

Congrats on jumping in head first and making the beer, all grain no less.

I am really interested in how the next "yeast off" turns out. I had planned on brewing a NE IPA this week with 1318, but a family emergency came up and I will have to do it next week.

I am really interested in how the next "yeast off" turns out. I had planned on brewing a NE IPA this week with 1318, but a family emergency came up and I will have to do it next week.

The 2 were made from the same wort, with the same hop additions. Only difference was yeast and different containers. I did have transfer issues with the WLP007 and it ended up bring open transfer and not sure if during that process something got contaminated as I had to play around with the keg, the connecters and hoses quite a bit to try and get the beer in the keg. Very different beers right now.

Could be an oxidation issue, if it tastes stale.

I am really interested in how the next "yeast off" turns out. I had planned on brewing a NE IPA this week with 1318, but a family emergency came up and I will have to do it next week.

Me too. I thought WLP007 would have one round 1 as I kept hearing it was supposed to be what trillium is using, and I was trying to clone one of their beers. But to me the 1098 was much closer in smell and taste. WLP007 was closer on color only. The WLP007 taste a little pilsner like.

I might actually just do a full batch of 1318. I should still have plenty of 1098 in the keg for the next couple of weeks so should have something to compare to.

I might tweak the base recipe a bit, and add a bit of citra to the whirlpool. Think it will still be an all galaxy dry hop for this round. Also making sure I use carapils and not caramel malt 40L LOL.

Weather permitting, I am planning on brewing tomorrow. Will see, also have a sick wife, so life might intervene but I have a yeast starter spinning around stir plate as we speak. Doubled the size as last time it was the worlds smallest yeast starter

Hers an image of the 2 beers. WLP007 on the left. WL1098 on the right. It also highlights the carbing issue with the 007. I still think there is something really wonky up with the keg connectors. I think its going back as soon as the keg is kicked as I have had nothing but issues and its brand new.

Similar threads

- Replies

- 3

- Views

- 581

Historical Beer: Roggenbier

Roggenbier with spices

- Replies

- 3

- Views

- 1K