Most of this type of thing, if it is available here, is only available in trade stores. Shopping in a trade store (electrical or plumbing supply, painting supply, welding supply, etc) requires that you have a business that is registered for doing business in that particular field. They don't sell to private people, only business accounts and they check the business register when you open an account. In other words, you need to be a licensed plumber, electrician, etc to shop at those places.

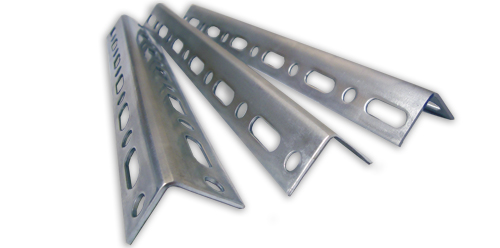

Most of the stuff available to private people is in kits. Self fabrication of various items is strongly prevented by the trade unions. Even to import that strut for 300, it would need to go to a plumbing supply and I would have to convince some plumber to go there and buy it for me - who would probably want a markup.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)

)

)