Mothman

Well-Known Member

Those that have their mill mounted in/on a bucket (or other), do you take the mill out to clean it? Or is cleaning it actually a necessary thing?

OK. I don't have anything fancy shmancy like an air compressor, but I can probably get er done with some inverted banging. lol

Main thing is, I'm not needing to actually wash it, good to know.

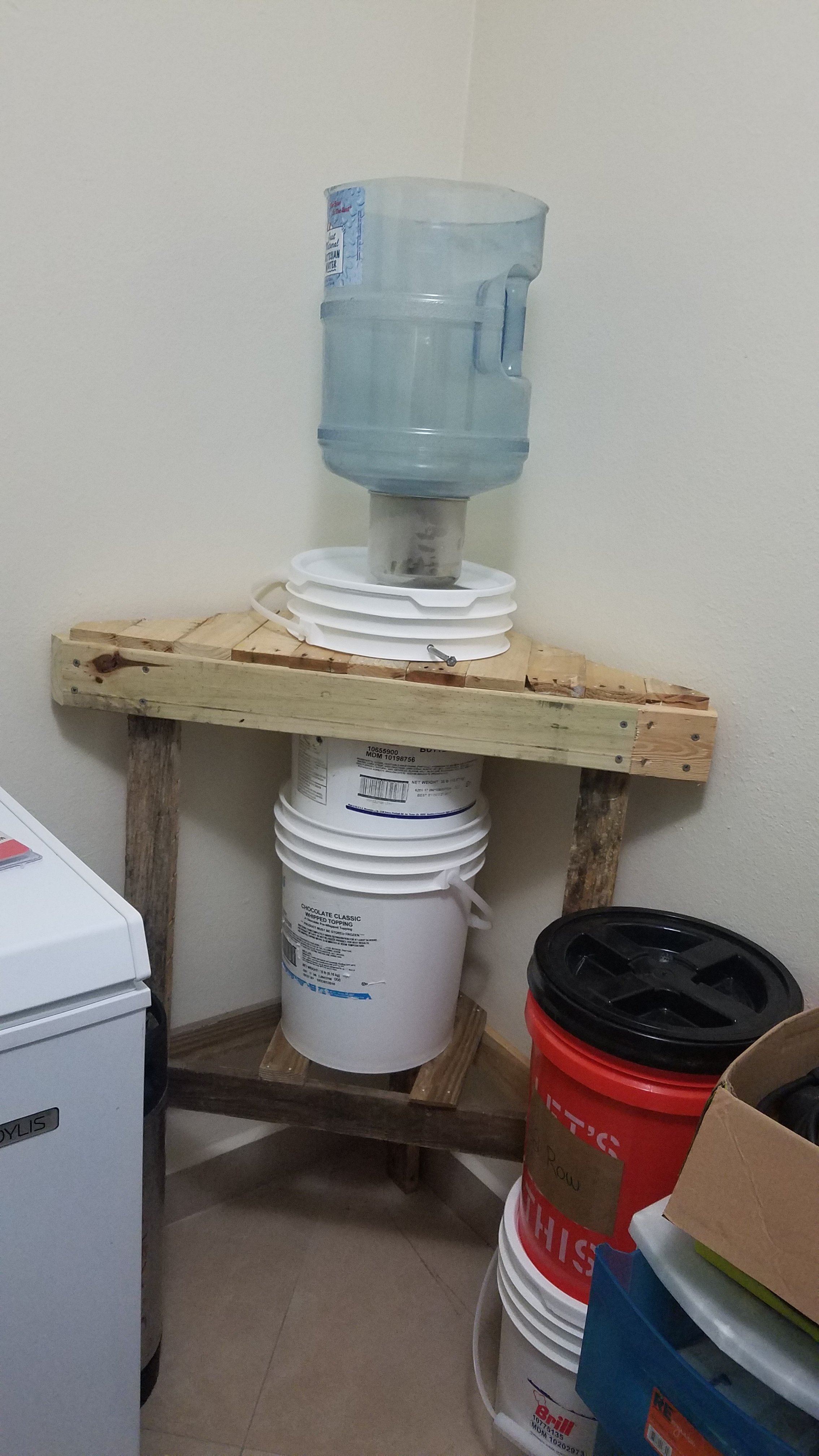

AFAIK all home center 5 gallon pails are the same size, and should be big enough.Are the 5 gal homer buckets big enough for these mills to fit down into? Or are people using larger, maybe 6 gal buckets.

Forgot to update... I used my ugly milled grain for the first time a couple weeks ago. Only hit about 72% efficiency.

So I tightened it up a couple spins and will try again next time.

Conversion efficiency always confuses me... But using the Brewer's Friend efficiency calculator, I input my grain bill, and for volume, if I'm wanting to find my conversion efficiency I think I use my strike water volume?

And for gravity I used my preboil gravity.

That gave me about 80% in the calculator, and I think that's conversion efficiency using the numbers I did?