janitorjerm

Well-Known Member

Is there a reason for using a washer larger than the center of the fan? Also, should my two magnets be set to have the same poles facing up or should one be "N" and the other "S"?

janitorjerm said:So one should be set with N facing up and the other with S?

DoctorMemory said:So why do you need a speed control? Do you start out fast then slow down as you get more slurry, or do you need to tweak the speed for different types of yeast? K I'm just wondering if you really need the speed control, or if you can just use a resistor to set a fixed speed.

The OP pictures show the wires going to the potentiometer looking like they are just wrapped around the posts. I attached female quick disconnects the the wires leading to the posts but they keep falling off. Can I just wrap them around the post without soldering?

Blackhawkbrew said:made this up per OP directions (with help from this thread!). One more question. The OP pictures show the wires going to the potentiometer looking like they are just wrapped around the posts. I attached female quick disconnects the the wires leading to the posts but they keep falling off. Can I just wrap them around the post without soldering?

Once again I'm making DIY projects WAY harder than they need to be!

Blackhawkbrew said:made this up per OP directions (with help from this thread!). One more question. The OP pictures show the wires going to the potentiometer looking like they are just wrapped around the posts. I attached female quick disconnects the the wires leading to the posts but they keep falling off. Can I just wrap them around the post without soldering?

Once again I'm making DIY projects WAY harder than they need to be!

r8rphan said:a) In every picture I see of a computer fan, there are bars connecting the frame of the fan to the motor in the center. this makes sense as the thing has to be mounted some how... Do the fans typically have these on both sides or do I have to find one with them on only one side? IF so, how do I do this seeing as nobody seems to show pictures of both sides? Or is it okay to cut the frame connecting bars away on one side?.. Or better yet can someone point me to an affordable one that is 'recommended' for this purpose?

r8rphan said:b) What size stirrer should I get.. I was going to get one that was 1" long with a rib in the middle... is that large enough?

r8rphan said:PS.. my plan is to make a wood disk with a perfectly centered recess to hold the magnet (I have a CNC router) and mount that on the fan... I was also planning on carving the box out of wood... how is the wood disk (steel washer in the original post) attached to the fan.. silicone? and what is the optimal distance the fan magnet should be from the bottom of the flask?

Just finished building mine! I ended up using a 90mm fan with a 12vdc power supply. I made my own stir bar and the whole assembly works wonderfully. I had to make some "modifications" to the fan, however. The fan would not sit high enough for good contact so I cut the 4 top screw holes off to give me some added height. I used nuts to adjust the height accordingly after that. Thanks for the article!

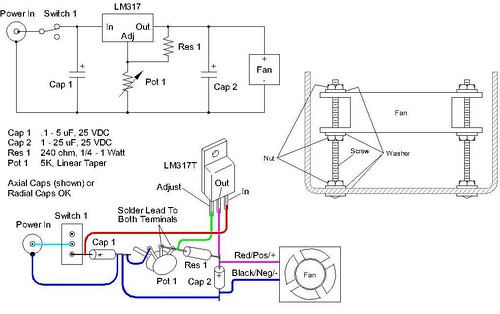

This is a fool proof wiring diagram. All parts is obtainable from your local Radio Shack.

This will allow for perfect speed control. Using just a potentiometer will work at first but wont last and last. You wont get good speed control and using lower volt DC adapters for speed control is silly. Don't do it, build it right.

Also checkout this handy link: http://www.stirstarters.com/instructions.html

If you like DIY then build one if not just order one from here, it is much easier and only marginally more expensive than parting and building it yourself.

Cheers to happy yeasty beasties!

For the money all of these additional parts would cost, would I just be better off buying a stirplate?

Since some of the parts comes in packages of two or more, I just ended up making 2 stir plates and gave one to a friend! But yes you will need some sort of heat transfer from the LM317t. You can cut some copper or aluminum plate and drill a hole and screw it to the LM317t with some thermal paste. I ended up snapping the piece of copper I had and ended up purchasing a tiny aluminum one from radio shack. (http://www.radioshack.com/product/i...ce=CAT&utm_medium=RSCOM&utm_content=CT2032230)

I made 2 stir plates based on the original post and both work fine, but I have some questions based on what others are doing:

1) why use resistors, capacitors and the LM317T? I didn't and my stir plates work. I just wired up an on/off switch and a pot and the fan.

2) does anyone have a good fan recommendation? I took both of mine from old computers. One came from a Mac and is clearly better-made and has no trouble spinning a 2" stir bar in a 2L starter. The other is a cheapie from a crappy PC and can only spin the 1" stir bar in a 2L starter - the 2" bar can stop the fan from spinning! I tried a third cheapie fan and it's no better, maybe worse.