user 163849

Well-Known Member

- Joined

- Jul 16, 2013

- Messages

- 296

- Reaction score

- 96

I actually have no real pressing need for a second temperature controller. I bought the second STC to keep as a spare in case the first one gave up on me.

But I decided to go ahead and build the second controller which makes it an even better spare, instant replacement with no wiring to do at the time of failure of the one that is in service.

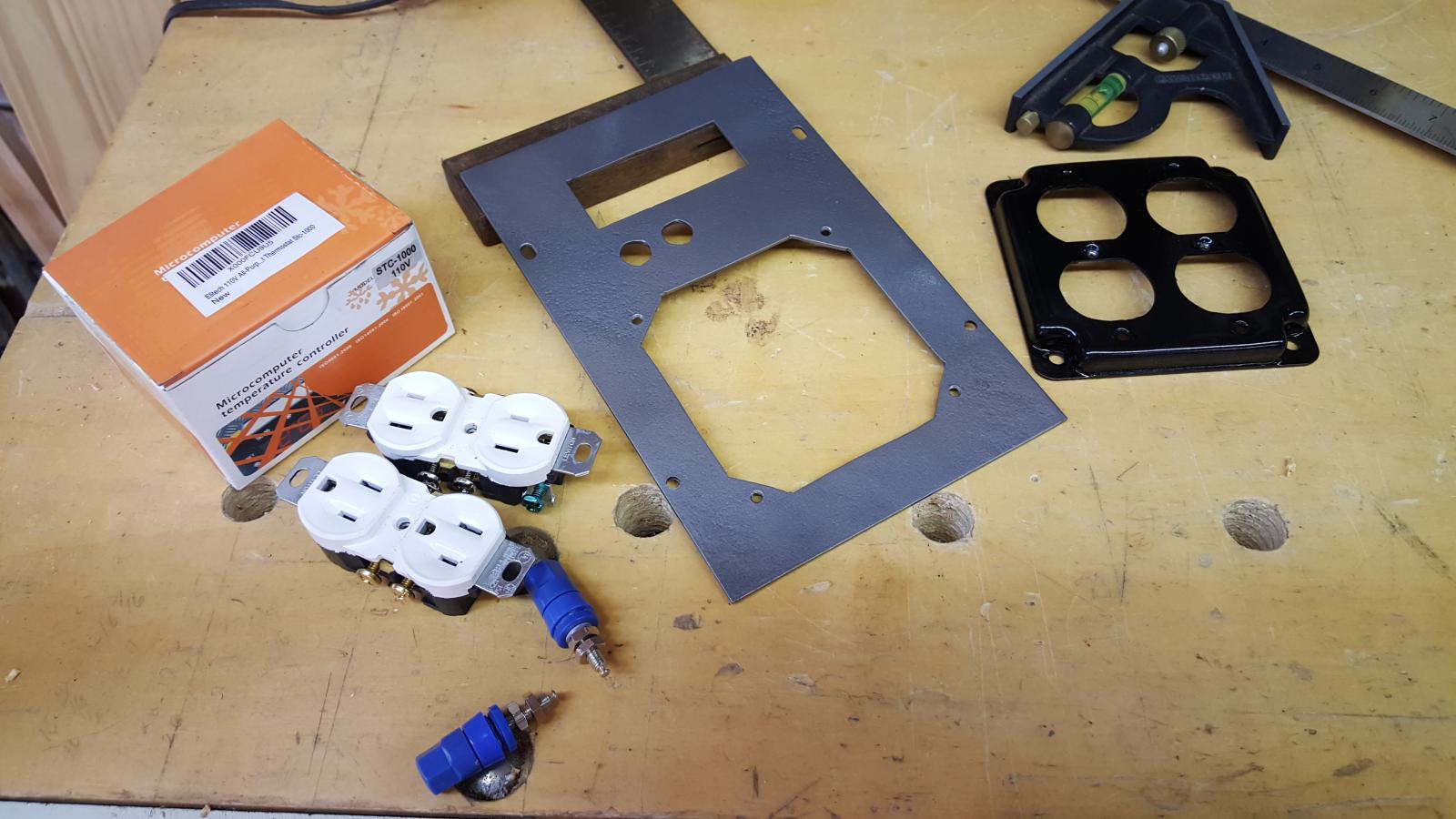

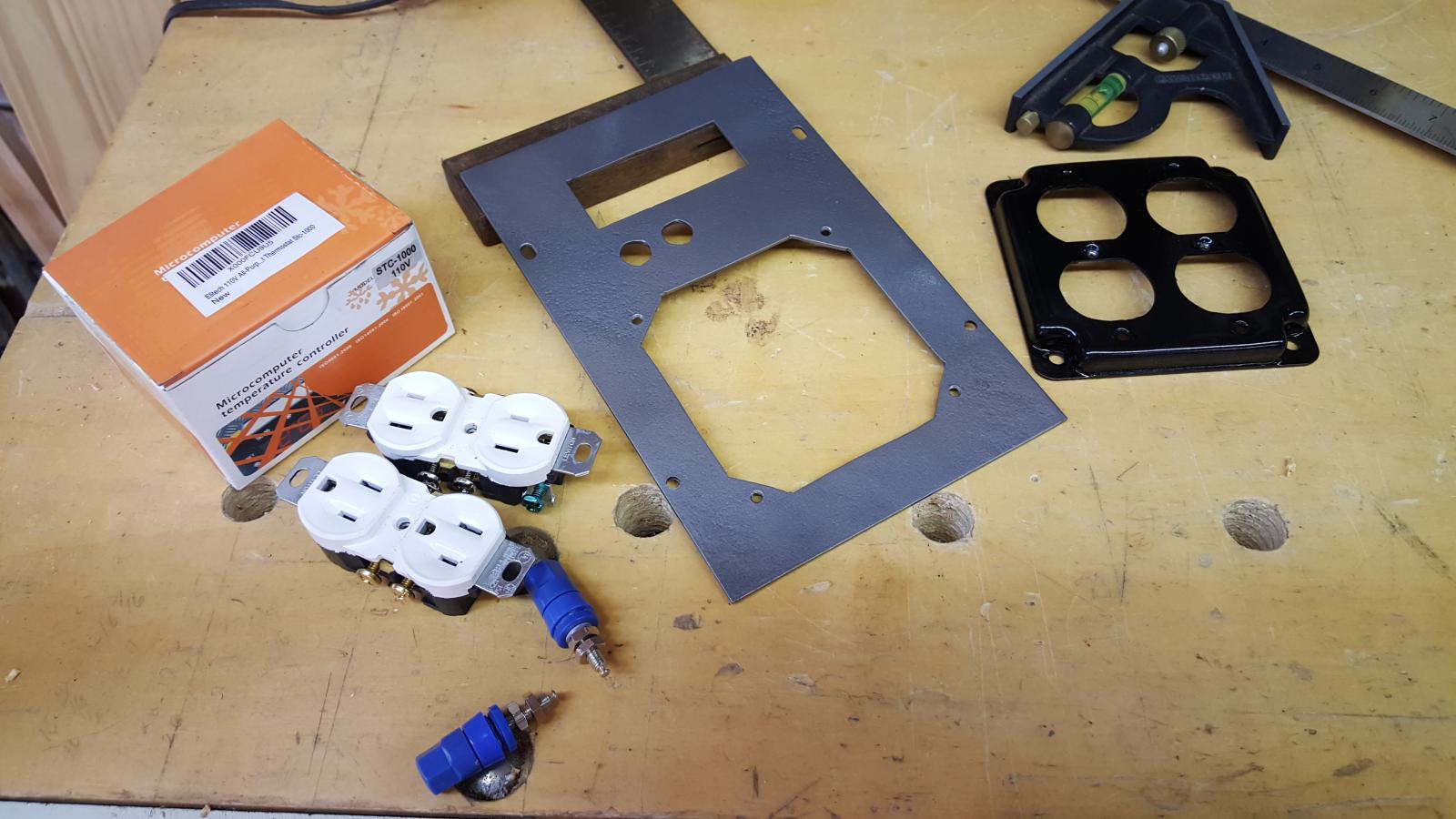

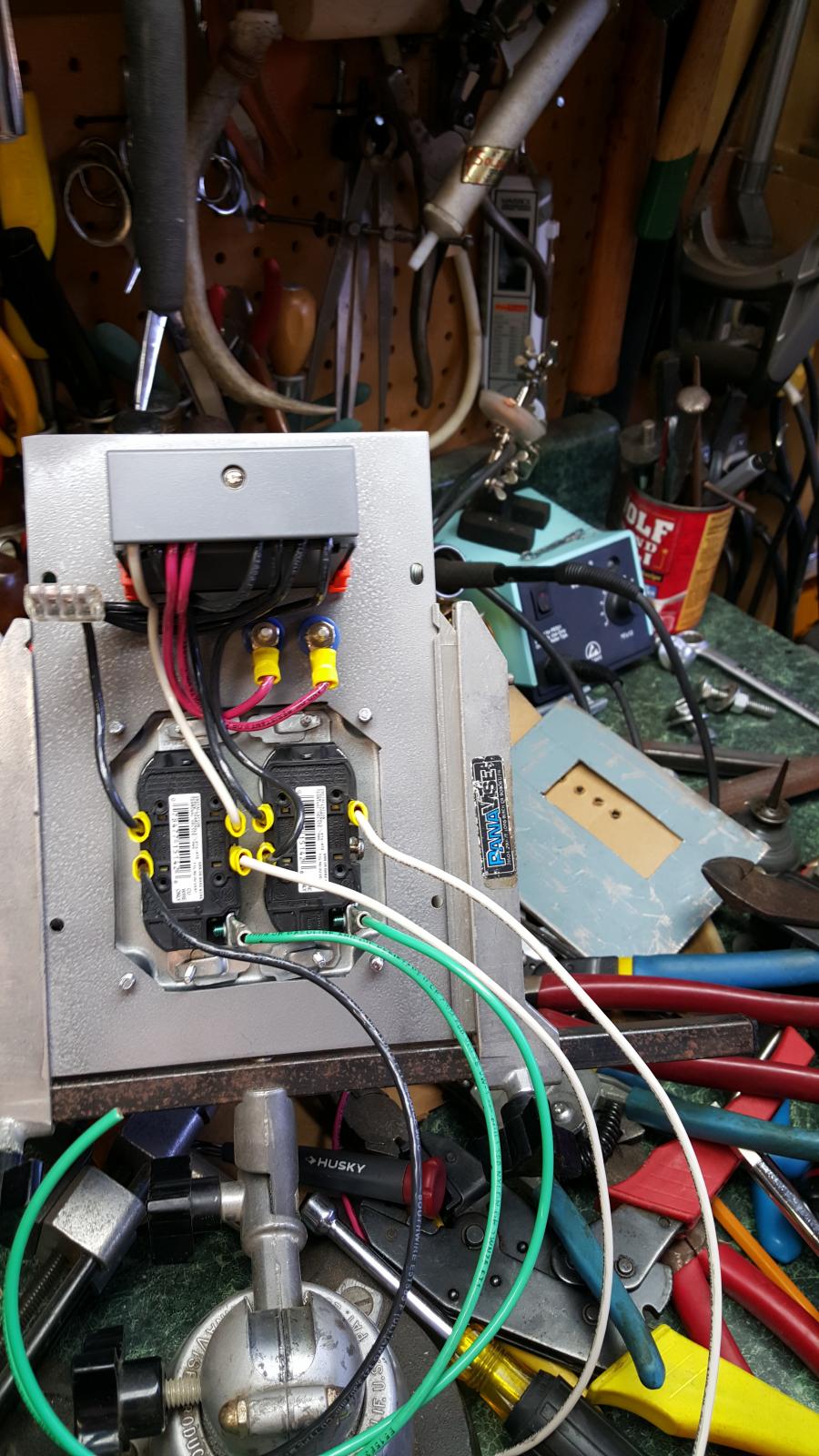

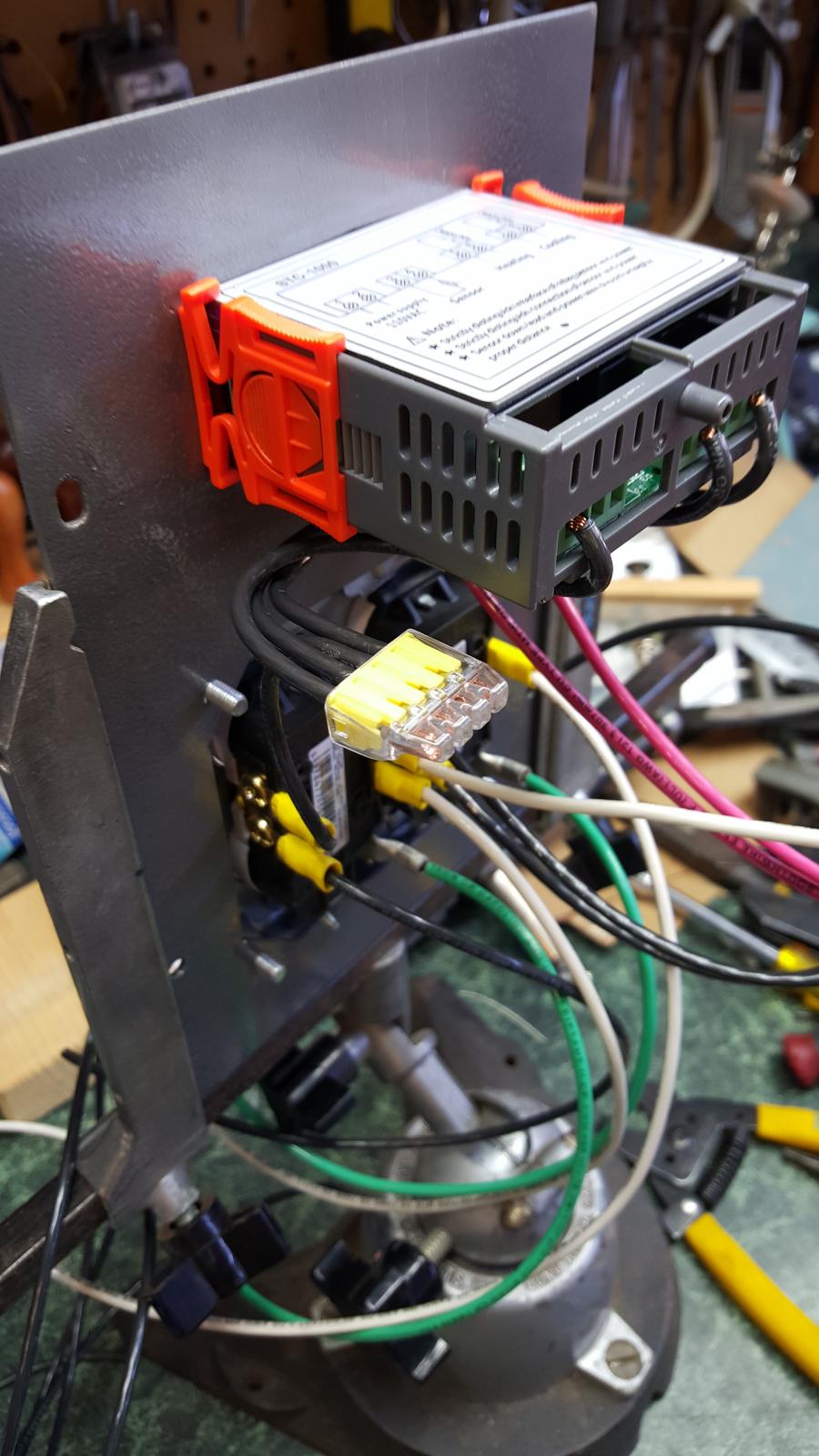

I decided not to fool with trying to cram everything into a tiny little box like I did the first time and started laying things out on piece of steel plate that happened to be laying in the floor of my shop. The plate is approximately .080 inch thick, heavier than needed by a long shot but it will work. After I positioned everything where I wanted it on the plate, I cut out the holes needed and cut off the excess length of the plate, then removed the old paint and applied whatever paint I had on hand.

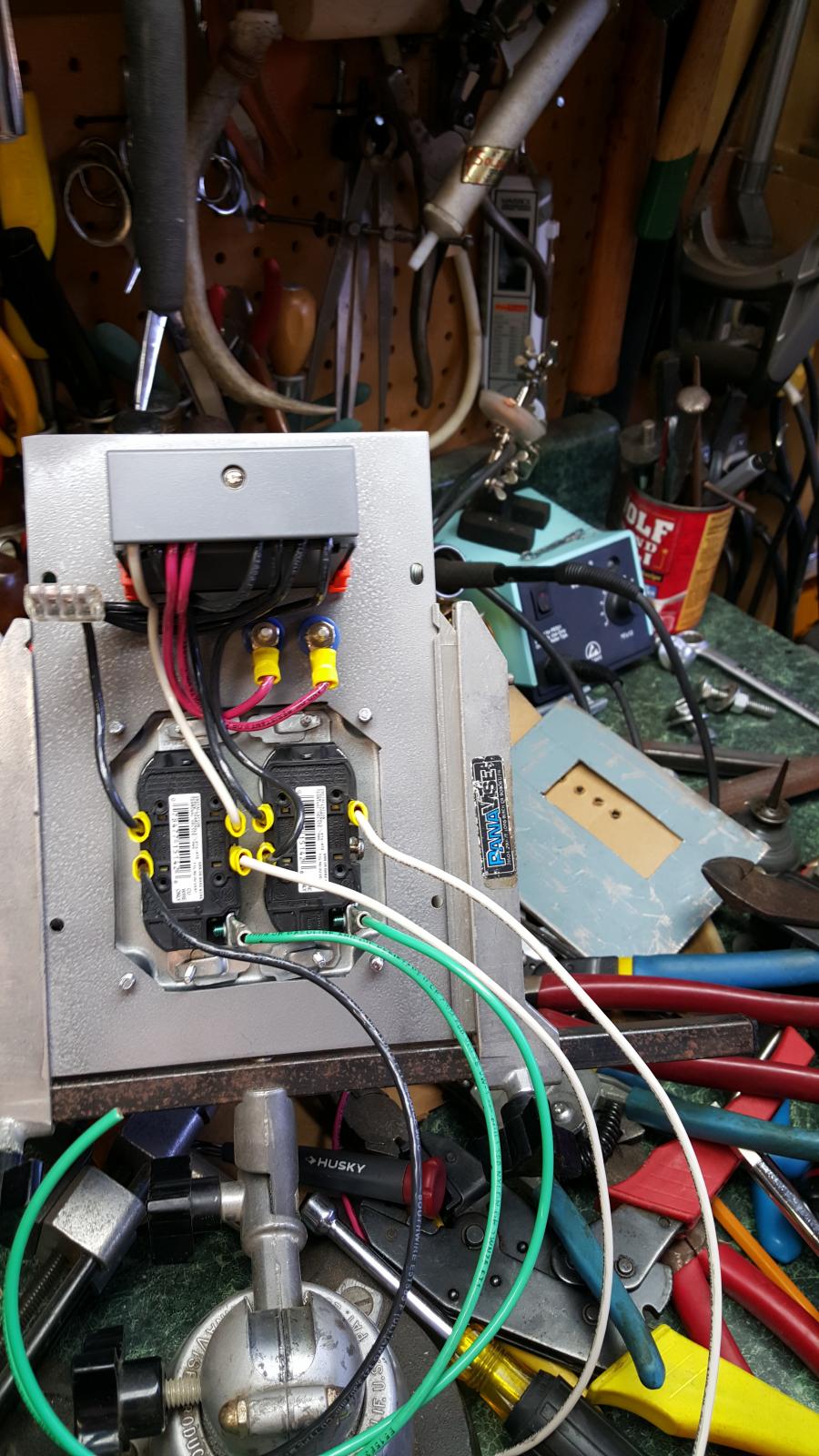

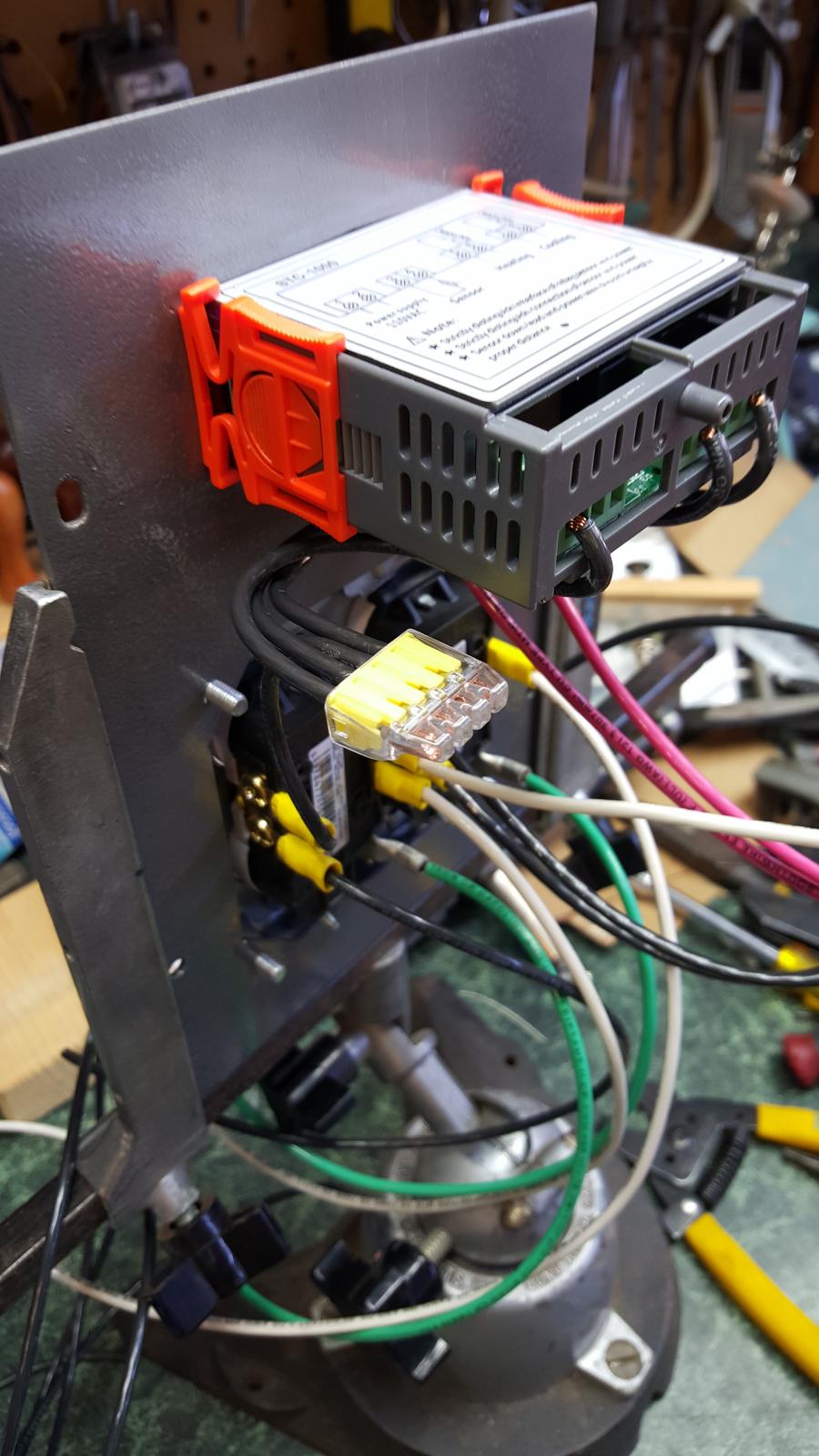

I just got around to wiring it up before I stopped for lunch today. I still need to find or build a box for the face plate to mount to but it is only lacking a power cord to be a working temp controller as it is.

This is what I have done so far.

But I decided to go ahead and build the second controller which makes it an even better spare, instant replacement with no wiring to do at the time of failure of the one that is in service.

I decided not to fool with trying to cram everything into a tiny little box like I did the first time and started laying things out on piece of steel plate that happened to be laying in the floor of my shop. The plate is approximately .080 inch thick, heavier than needed by a long shot but it will work. After I positioned everything where I wanted it on the plate, I cut out the holes needed and cut off the excess length of the plate, then removed the old paint and applied whatever paint I had on hand.

I just got around to wiring it up before I stopped for lunch today. I still need to find or build a box for the face plate to mount to but it is only lacking a power cord to be a working temp controller as it is.

This is what I have done so far.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)