Backstory:

We have started brewing bigger batches and as such have moved to using larger (50 L) kegs for ease of storage and reduction of cleaning. The issue with this is that my keezer cannot fit very many of these. Im used to being able to hold 6-7 20 L kegs in the keezer, but now I can only get 2 big kegs in there This seriously limits its flexibility and has hindered my beer selection.

Current keezer:

I didnt want to buy bigger/more chest freezers because they are big, ugly, expensive to run, and require a lot of heavy lifting to get full kegs into it.

Several months ago I asked the forum about the feasibility of a system which uses a window AC unit to chill the water bath in a Jockey Box (https://www.homebrewtalk.com/f51/possible-kegerator-alternative-glycol-cold-plate-428673/). I didnt get a lot of feedback from that which meant either: it was a dumb idea, or, nobody had really done something like this before. I was hoping it was the latter.

After a lot of thinking and planning, I decided I would give it a shot. There were some unknowns that could only be answered by testing it in real life.

The Build:

The idea for the project is this: I want to build a jockey box with a cold plate, and use the evaporator coils from an air conditioner to chill the water (or glycol mix) bath. I would control the temperature of the water bath with an Arduino to give the most in terms of flexibility. I will store the kegs in my basement crawl space at the ambient ~10-15°C (50-60°F). Ill need to increase my CO2 pressure to adequately carbonate at this temperature, but you generally need to run higher pressures anyway when pushing through a cold plate.

I bought a used AC unit for $25:

Started taking it apart and bending the evaporator coil out:

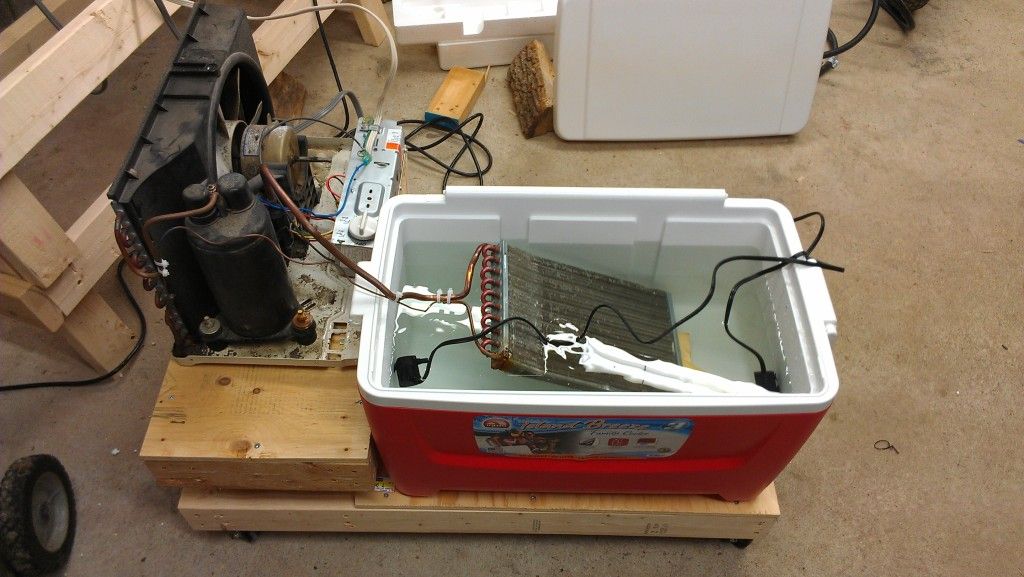

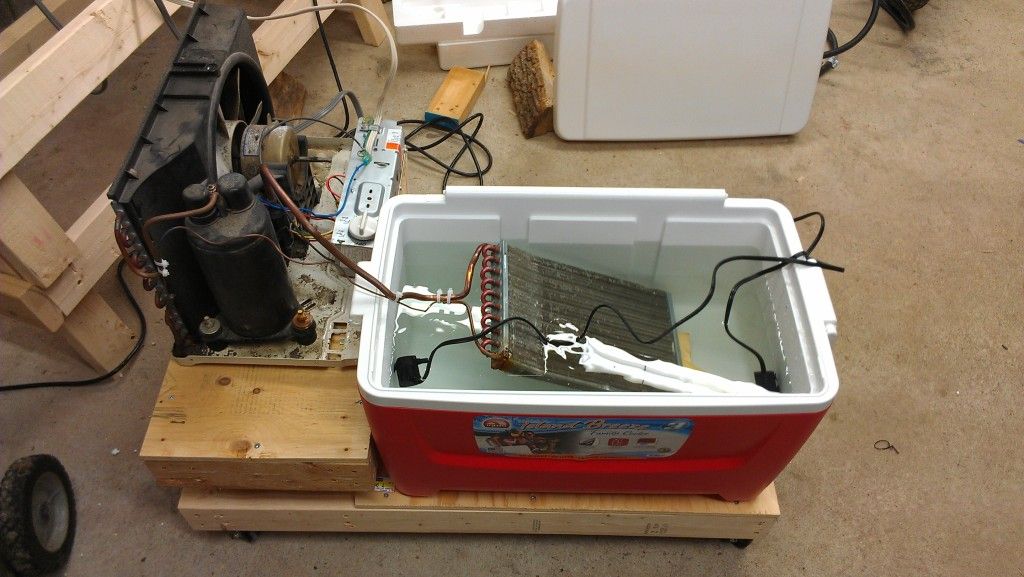

Fitting it into the jockey box cooler:

Making sure it still worked properly after my modifications:

I have placed 2 small aquarium pumps in the bath to ensure the water keeps moving.

Heres the final, assembled cooling system controlled by an Arduino. I made a manifold on the cooler lid with flared bulkhead fittings so I can easily attach my in/out lines to the cold plate. I have 6 circuits total in this system. I only have one circuit hooked up so far as my proof of concept.

Heres the back side of the wall where my taps will come through. I have not found a need to chill the lines between the cooler and the taps, as you would with a typical keezer trunk line. This is because the beer is carbonated at the ambient temperature so there is no real tendency for the CO2 to come out of solution in the lines. I no longer have to worry about being able to fit all my kegs into the keezer, because I have tons of room in the crawl space. If I get desperate, I could even build shelves to stack the kegs. This gives me the ultimate flexibility that I wanted.

I decided to spend the money and get the Perlick 525ss faucets. I then made a backsplash from aluminum, brushed with a scotch-brite pad, and made a drip tray for everything. The inaugural first pour:

I have the system set to 5°C (40°F). I have not actually measured the temperature of a pint that comes out, but it feels/tastes just about perfect! With the Arduino Im calculating the duty cycle that the AC unit is running at, and it is only on about 2% of the time. This is because (in addition to ambient losses) it only has to cool the beer that has passed through it.

As you can see there are still some empty taps, but I am working to get them filled up The end goal is to have 5 regular taps and one nitro.

The end goal is to have 5 regular taps and one nitro.

Cheers

We have started brewing bigger batches and as such have moved to using larger (50 L) kegs for ease of storage and reduction of cleaning. The issue with this is that my keezer cannot fit very many of these. Im used to being able to hold 6-7 20 L kegs in the keezer, but now I can only get 2 big kegs in there This seriously limits its flexibility and has hindered my beer selection.

Current keezer:

I didnt want to buy bigger/more chest freezers because they are big, ugly, expensive to run, and require a lot of heavy lifting to get full kegs into it.

Several months ago I asked the forum about the feasibility of a system which uses a window AC unit to chill the water bath in a Jockey Box (https://www.homebrewtalk.com/f51/possible-kegerator-alternative-glycol-cold-plate-428673/). I didnt get a lot of feedback from that which meant either: it was a dumb idea, or, nobody had really done something like this before. I was hoping it was the latter.

After a lot of thinking and planning, I decided I would give it a shot. There were some unknowns that could only be answered by testing it in real life.

The Build:

The idea for the project is this: I want to build a jockey box with a cold plate, and use the evaporator coils from an air conditioner to chill the water (or glycol mix) bath. I would control the temperature of the water bath with an Arduino to give the most in terms of flexibility. I will store the kegs in my basement crawl space at the ambient ~10-15°C (50-60°F). Ill need to increase my CO2 pressure to adequately carbonate at this temperature, but you generally need to run higher pressures anyway when pushing through a cold plate.

I bought a used AC unit for $25:

Started taking it apart and bending the evaporator coil out:

Fitting it into the jockey box cooler:

Making sure it still worked properly after my modifications:

I have placed 2 small aquarium pumps in the bath to ensure the water keeps moving.

Heres the final, assembled cooling system controlled by an Arduino. I made a manifold on the cooler lid with flared bulkhead fittings so I can easily attach my in/out lines to the cold plate. I have 6 circuits total in this system. I only have one circuit hooked up so far as my proof of concept.

Heres the back side of the wall where my taps will come through. I have not found a need to chill the lines between the cooler and the taps, as you would with a typical keezer trunk line. This is because the beer is carbonated at the ambient temperature so there is no real tendency for the CO2 to come out of solution in the lines. I no longer have to worry about being able to fit all my kegs into the keezer, because I have tons of room in the crawl space. If I get desperate, I could even build shelves to stack the kegs. This gives me the ultimate flexibility that I wanted.

I decided to spend the money and get the Perlick 525ss faucets. I then made a backsplash from aluminum, brushed with a scotch-brite pad, and made a drip tray for everything. The inaugural first pour:

I have the system set to 5°C (40°F). I have not actually measured the temperature of a pint that comes out, but it feels/tastes just about perfect! With the Arduino Im calculating the duty cycle that the AC unit is running at, and it is only on about 2% of the time. This is because (in addition to ambient losses) it only has to cool the beer that has passed through it.

As you can see there are still some empty taps, but I am working to get them filled up

Cheers

I'll put that on the to-do list!

I'll put that on the to-do list!