grbr

Active Member

- Joined

- Jul 4, 2020

- Messages

- 36

- Reaction score

- 42

Hello all!

Great staff, I am so glad I found this forum.

I am in the process of making my first batch, day 6 into primary fermentation. Whole grain malt/mash (so many new terms, I may still mix them).

I used 3.5kg pale ale, 3kg Pilsen and 0.5kg special Belgian (I am not sure about the name, but a dark and roasted above 100C). 41L water, 40gr Columbus, 20gr Amarillo, 20gr Cascade.

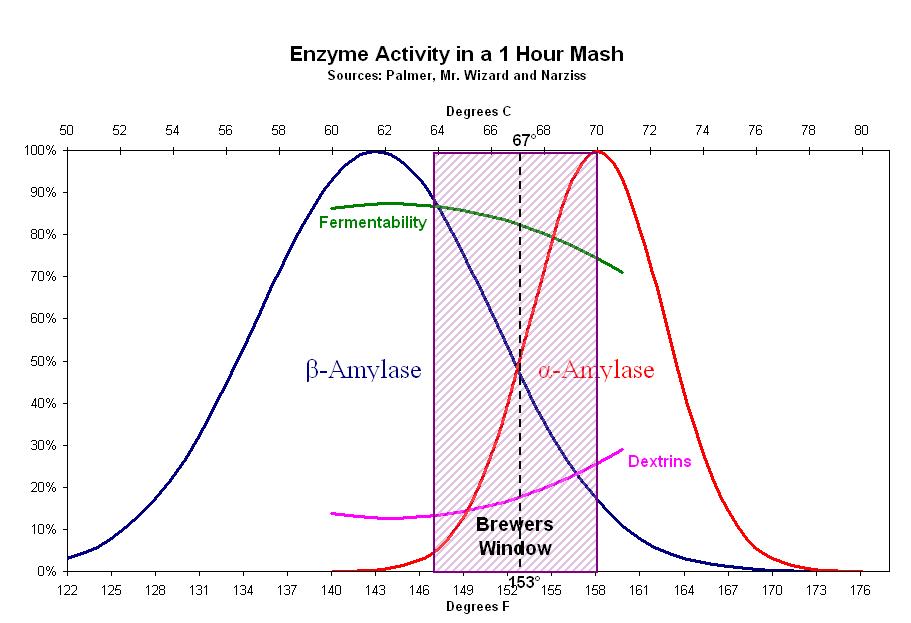

Mashing process 1 hour between 69-72C (planned 67C, but couldn't keep it). Additional 1 hour boil.

Due to no cooling equipment I pitched the yeast next morning (so previous Sunday) at 21C, 2 x 11.5 Fermentis dry yeast.

Below is the state same date after 12 hours.

And the state now

I do not see any visual activity. The temperature in the basement is 23C day/night. It was 21 when I pitched the yeast, but the weather got quite warmer the last week.

I plan to leave it as is for 2 more weeks and then bottling it.

I just hope it will become a beer at the end.

Greetings from North Macedonia, stay safe!

Great staff, I am so glad I found this forum.

I am in the process of making my first batch, day 6 into primary fermentation. Whole grain malt/mash (so many new terms, I may still mix them).

I used 3.5kg pale ale, 3kg Pilsen and 0.5kg special Belgian (I am not sure about the name, but a dark and roasted above 100C). 41L water, 40gr Columbus, 20gr Amarillo, 20gr Cascade.

Mashing process 1 hour between 69-72C (planned 67C, but couldn't keep it). Additional 1 hour boil.

Due to no cooling equipment I pitched the yeast next morning (so previous Sunday) at 21C, 2 x 11.5 Fermentis dry yeast.

Below is the state same date after 12 hours.

And the state now

I do not see any visual activity. The temperature in the basement is 23C day/night. It was 21 when I pitched the yeast, but the weather got quite warmer the last week.

I plan to leave it as is for 2 more weeks and then bottling it.

I just hope it will become a beer at the end.

Greetings from North Macedonia, stay safe!