So I have a Cereal Killer grain mill and want to motorize it. A friend gave me an electric motor pulled from a Ryobi Band Saw (model BS901). It has no markings anywhere showing it's specs. He says he thinks it's 1/2hp and 1725rpm. The specs of this saw state that it draws 2.1amps and operates at 2900SFPM, maybe this helps to tell me power and rpms but not sure. To me it looks smaller then 1/2hp's I've seen on ebay but I'd like to give it a go and try hooking it up directly using a gear reducer but have a couple questions.

1st question how do I know if it has a capacitor, it has a 3" long rounded rectangle hump on the side, is that a cap?

2nd this motor has 3 wires, white, black and green. Will I be able to hook it up to be reversible and do I need reverse?

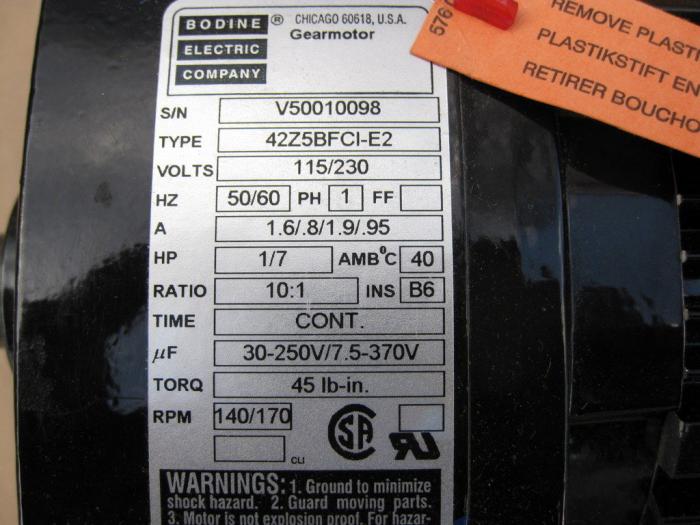

3rd question, will adding a 10:1 gear reducer give more torque if the motor is indeed underpowered?

I do understand the sheaves/pulleys would be a cheaper option but I have a 4yr old boy that touches everything, especially switches.

Sent from my iPhone using Home Brew

1st question how do I know if it has a capacitor, it has a 3" long rounded rectangle hump on the side, is that a cap?

2nd this motor has 3 wires, white, black and green. Will I be able to hook it up to be reversible and do I need reverse?

3rd question, will adding a 10:1 gear reducer give more torque if the motor is indeed underpowered?

I do understand the sheaves/pulleys would be a cheaper option but I have a 4yr old boy that touches everything, especially switches.

Sent from my iPhone using Home Brew

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)