dharvey1976

Member

- Joined

- Dec 11, 2011

- Messages

- 13

- Reaction score

- 3

Hi all,

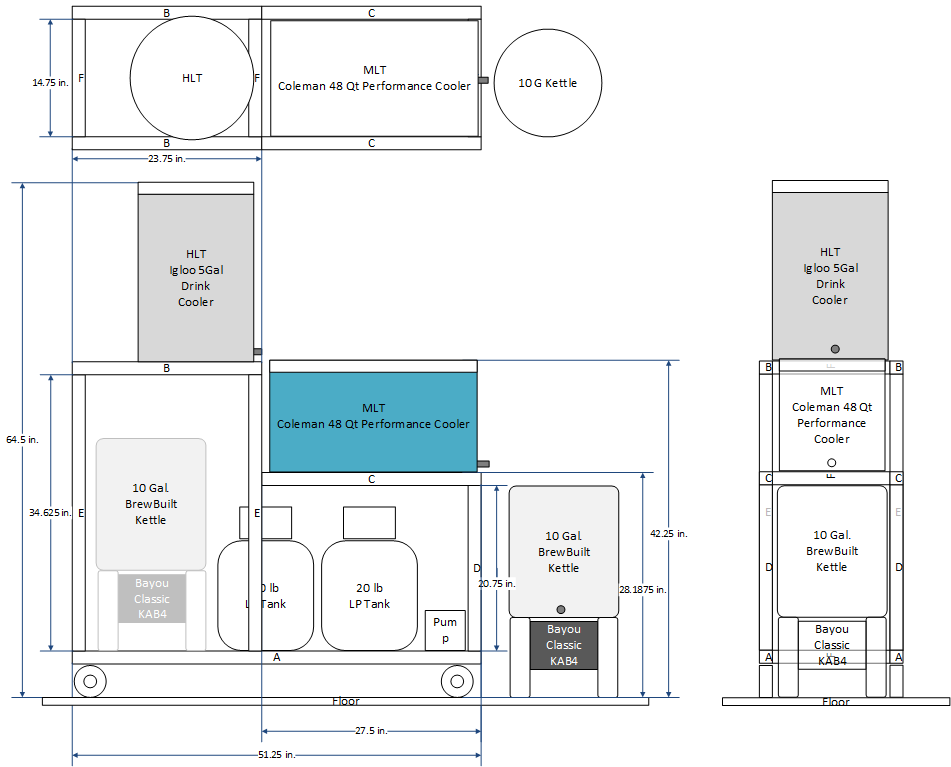

I have been developing a modular Brew stand and could use some feed back. my goal is to fill the gap between a turkey fryer and the multi thousand dollar brew stands. These do not rust. They can stack in many different configurations. I have few pictures below. I have used this modular system as a two tier and three tier and it works great.

As a home brewer is this something any one would be interested in purchasing? If not why? Is it missing something that most people would like? That kind of stuff

please let me know your thoughts

I have been developing a modular Brew stand and could use some feed back. my goal is to fill the gap between a turkey fryer and the multi thousand dollar brew stands. These do not rust. They can stack in many different configurations. I have few pictures below. I have used this modular system as a two tier and three tier and it works great.

As a home brewer is this something any one would be interested in purchasing? If not why? Is it missing something that most people would like? That kind of stuff

please let me know your thoughts

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)