I have been experiencing incomplete ferments.. Now that I have a means to easily take samples, and can see that that is what is happening, I need to find out how to fix it...

Seeing as the beer tastes the same as was happening with the old system, this is a problem that is definitely occurring on the fermentation side of things...

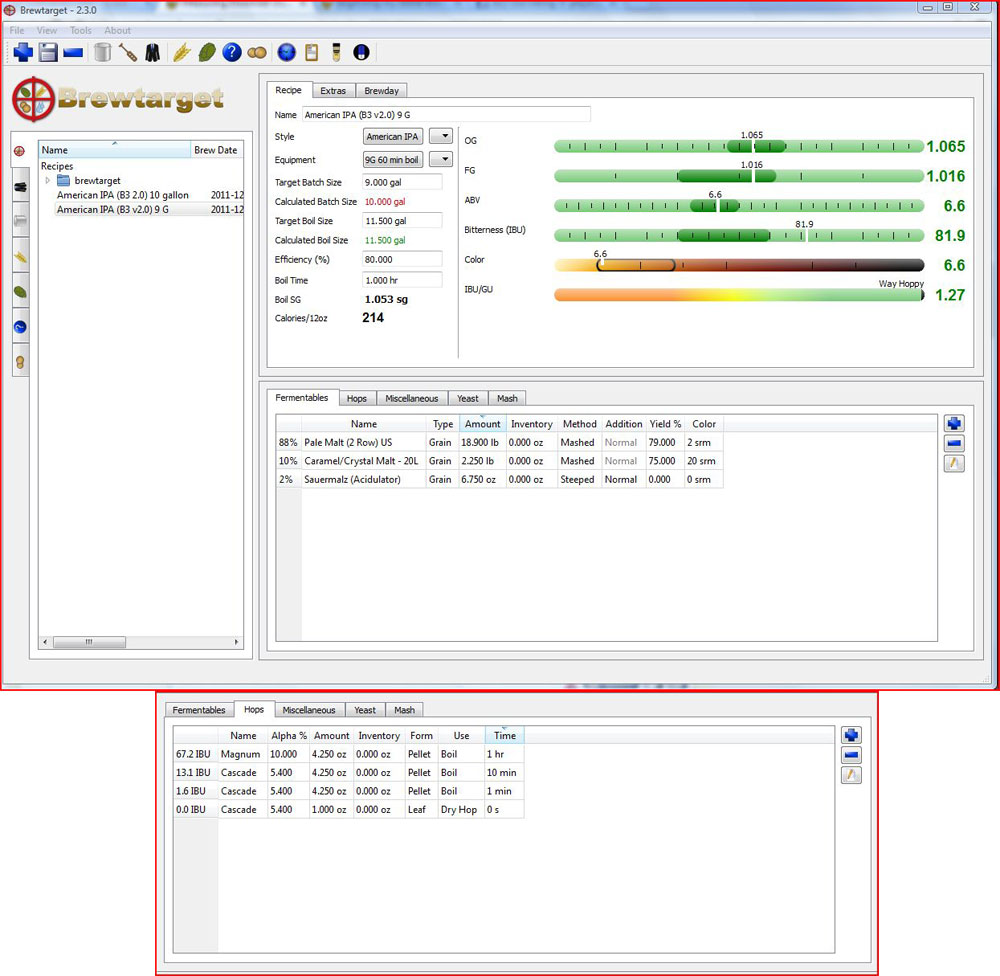

I'm getting complete conversion (iodine test), efficiency off the charts (88% measured with refractometer), but incomplete fermentation (.065 OG finishing at around .030, way short, measured with both refractometer/calculator and hydrometer, with matching results)

So, seeing as there are only three components to a successful ferment.. Sugars, temperature, and oxygen... It has to be one of those three things causing the problem...

I pitched two packets of US 05 into a 10 gallon batch at 66 degrees... Once it stalled, I tried shaking it some, upping the temp, etc.. no restart.. I then made a starter out of four more packets, and pitched that.. 'no effect'.... So, I'm thinking there wasn't enough oxygen in the wort to complete fermentation... It's the only thing I could not measure...

The fermentation chamber keeps everything pretty dang stable (verified by the fermometer strip on the Speidel), and I can't believe that I've been having 'unfermentables' problems over many many brews, with two completely different breweries.... This new brewery even involves the use of RO filter and building up the water profile from scratch...... So it has to be the oxygen..

Dumping the air stone in the kettle prior to transfer method, and going with pure oxygen being injected right as it goes into the fermenter... But don't know how to measure if i'm injecting enough or too much....

Ideas?