I've been trying to get into this for a long time with it keep getting knocked off the project list. I finally got all my components together and am putting it to use!

Goal: CP to control two elements, one at a time, and one pump. Simple, no frills repeatable controls.

Existing equipment:

8 gallon stock pot, 15 gallon keggle, 48 qt mash tun cooler, Great Breweh (Topsflo) 12 VDC pump with AC adapter.

New Equipment:

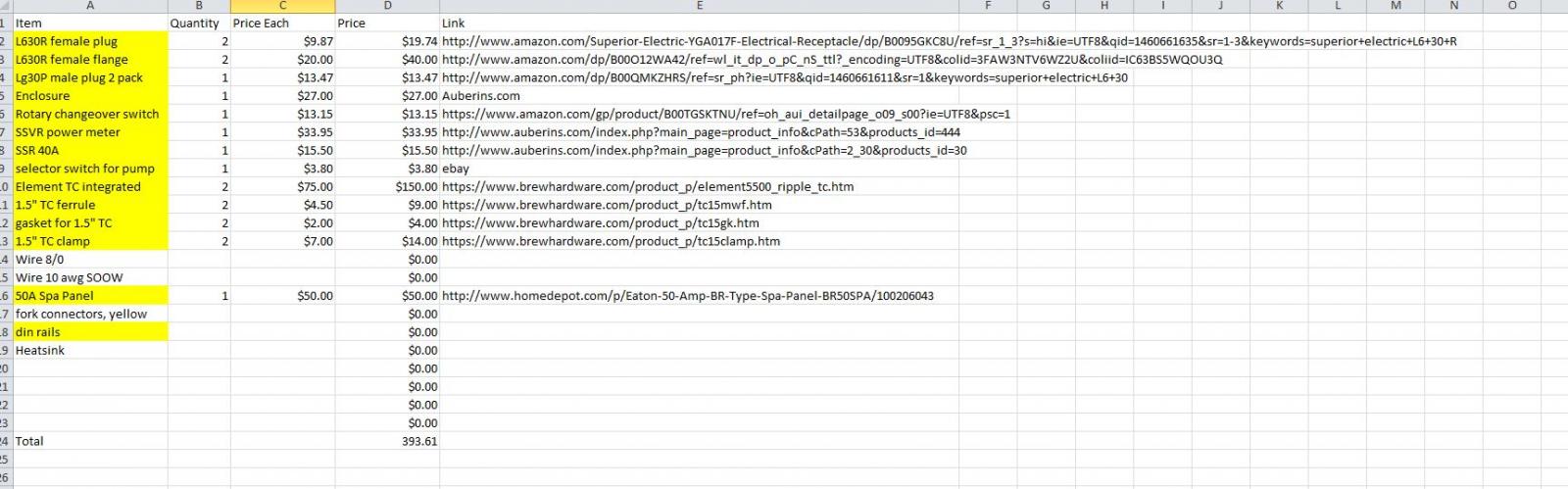

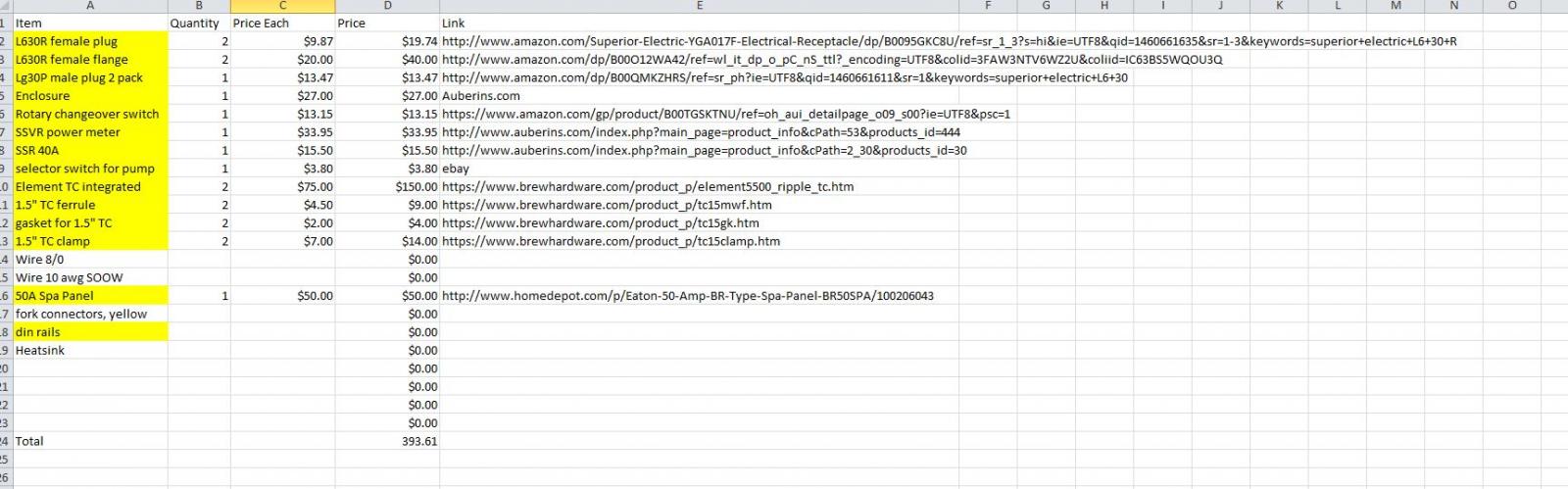

On that screenshot

I started on this today and while at Lowe's picking up more things, the guy in electrical confused the crap out of me. He was saying that I needed a breaker before every device that's rated for said device. He also said that everything downstream should be matched (wire and breaker) for the upstream breaker. I was under the impression that everything downstream should be equal to OR LOWER than the breaker.

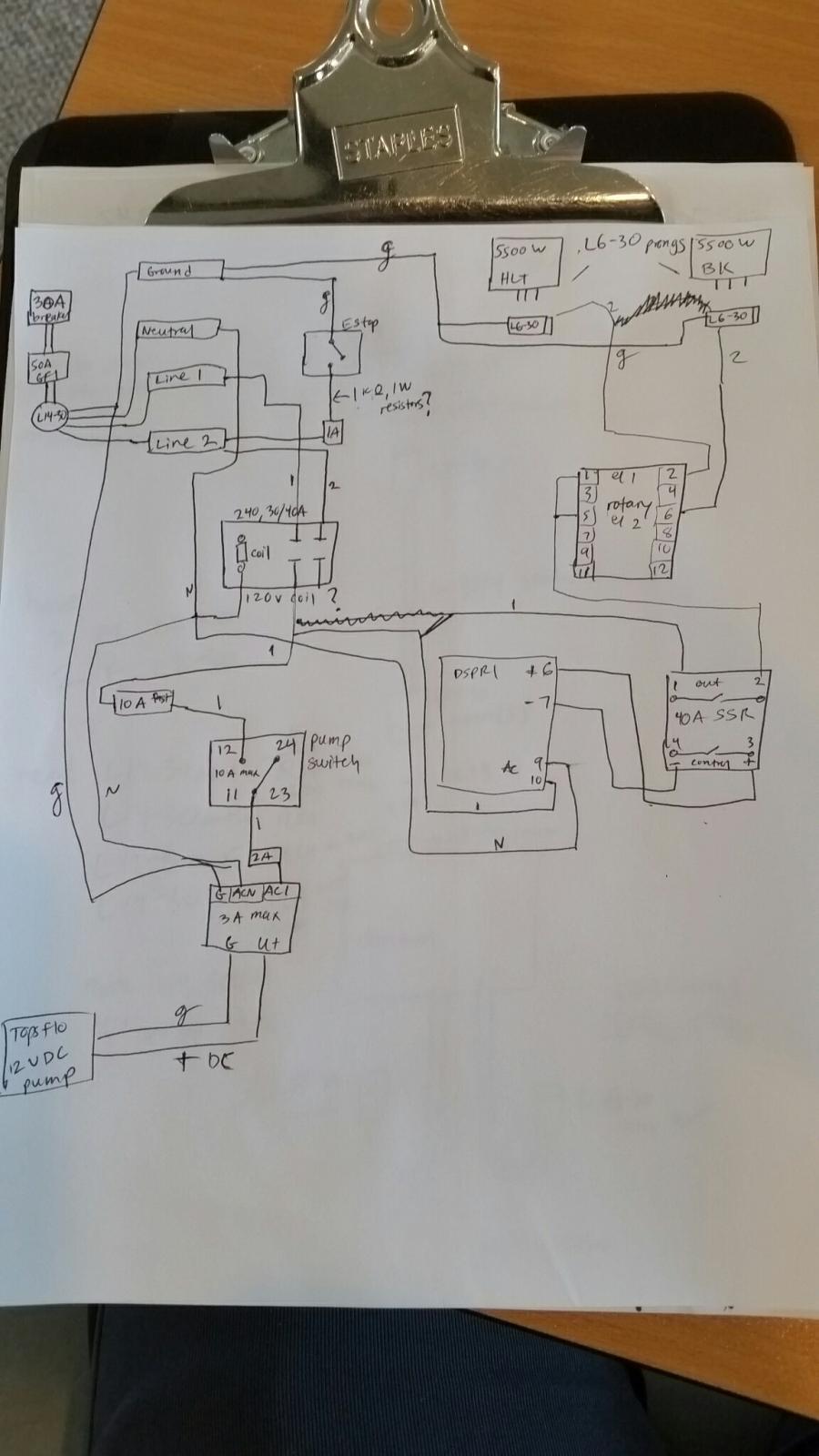

Here was my plan:

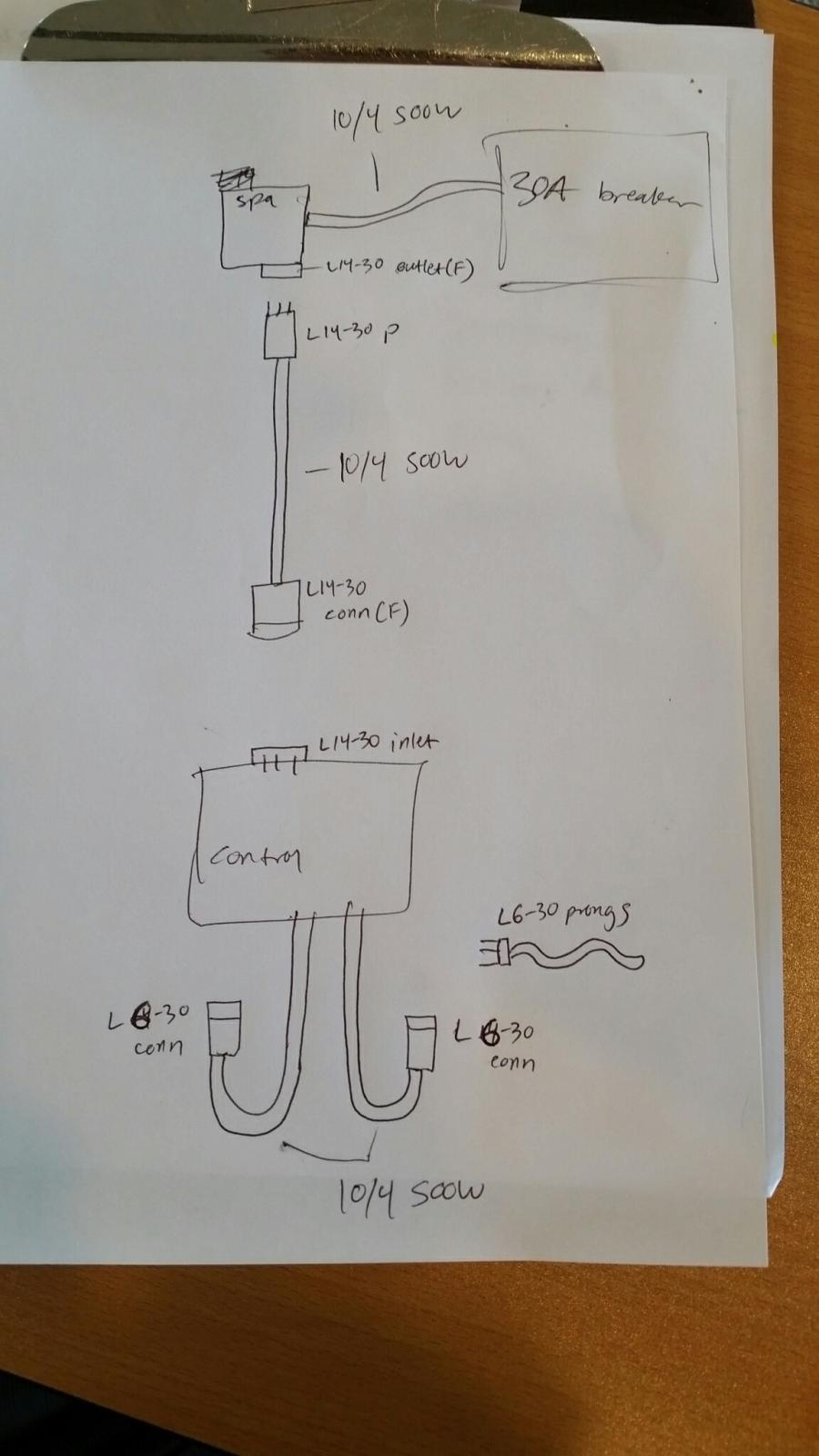

Home panel contains 50 amp breaker -->>8-3 wire-->> Spa Panel with 50 A GFCI (because 30 amp GFCI breaker itself cost way more -->> 8-3 wire-->> control panel.

From the spa panel to the control panel is a two-male ended 10/4 cored with L6-30 male plugs on it. This is my extension cord if you will.

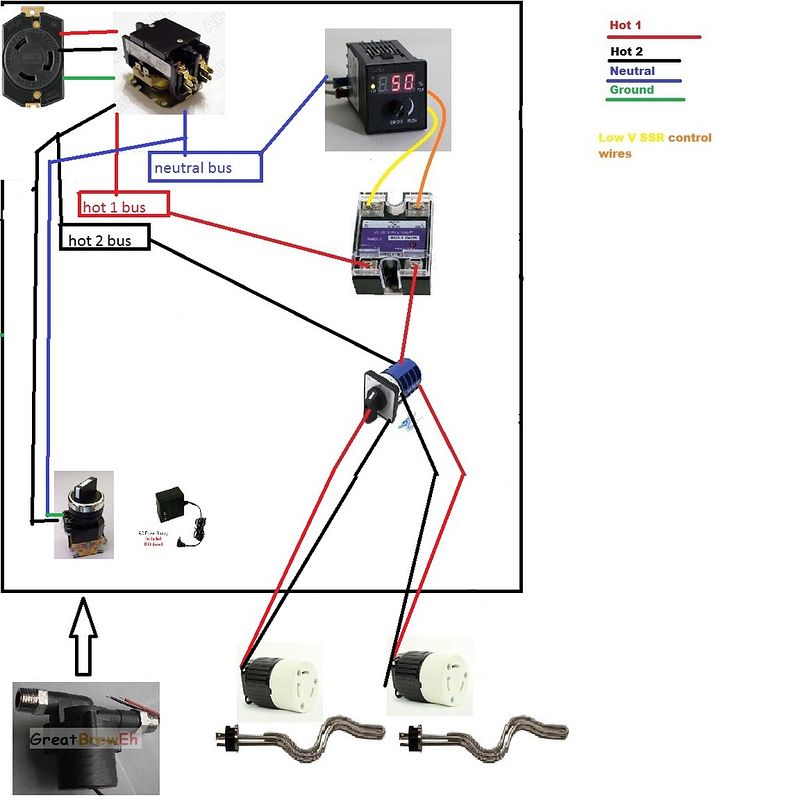

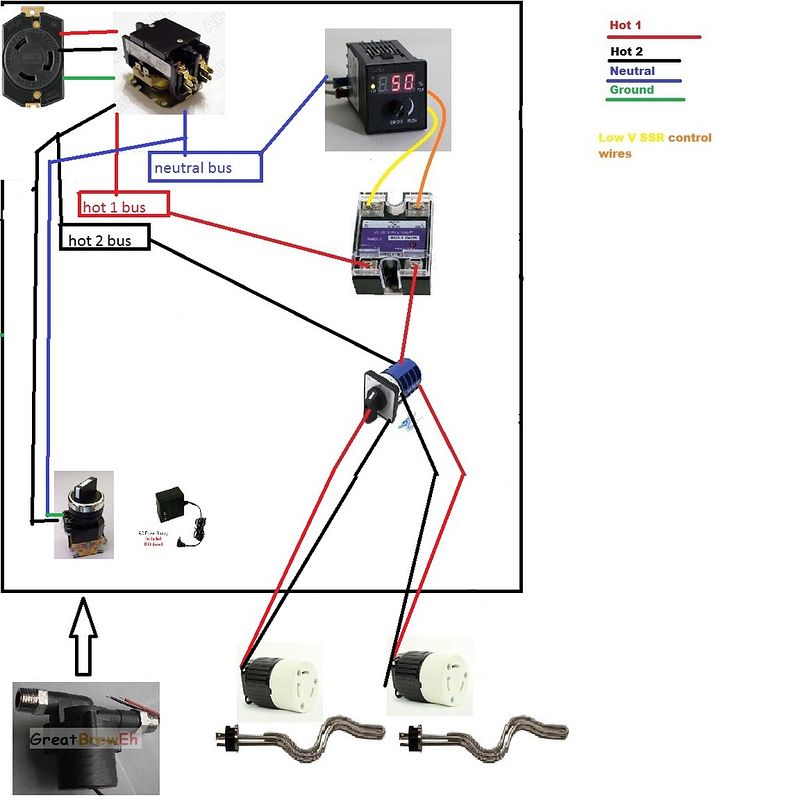

Control panel: input comes from the L6-30 receptacle > then goes into the 240 contactor with 120V coil > this provides power to the pump switch itself which is then going to the AC adapter which then goes to the pump AND to the SSVR and power meter which goes through the changeover switch into the element which is hardwired from the changeover to the female plug.

All the element stuff is with 10/4 wire, the pump with 14 gauge.

Notes: My elements are 5500W, so at peak it draws 23 amps, hence the 40 A SSVR for protection. I figure that a 40 A powered element under a 50 A GFCI is fine, yet the guy tells me I need a 40 A breaker in case more amperage finds it's way to the element. But I don't get it. It can only draw 23!!! no more will be sucked from it.

Also, for my pump he said to put a smaller breaker (like say 15 amp) before the pump. But again if it only draws 2 amps at 12 VDC (which will be downstream of the 120V AC adapter)...IDK now I'm confused.

My electrician buddy who helped me today said those breakers weren't needed, but he also said the contactor wasn't needed (the lowes guy didn't even know what a contactor was). I thought it was. How else will I get 4 wire from 3?

I feel like I'm missing a big "something" here. Can anyone help?

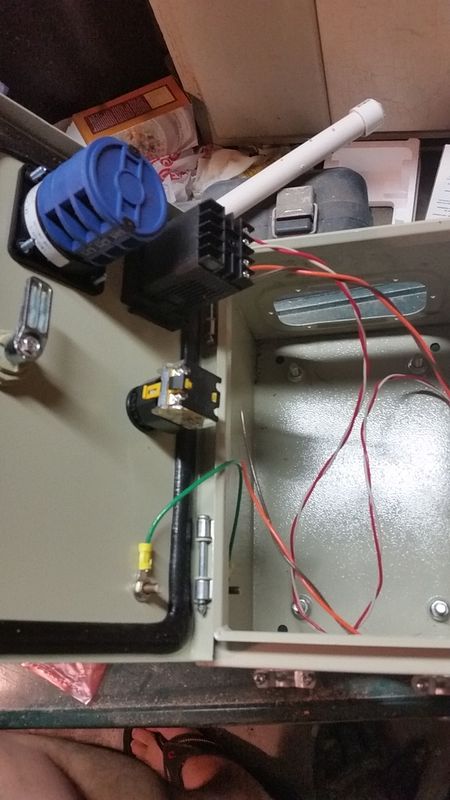

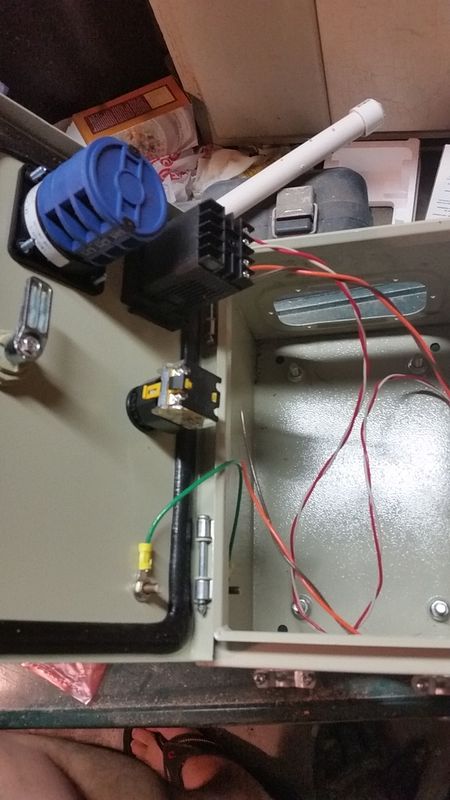

Here's what I have so far:

Goal: CP to control two elements, one at a time, and one pump. Simple, no frills repeatable controls.

Existing equipment:

8 gallon stock pot, 15 gallon keggle, 48 qt mash tun cooler, Great Breweh (Topsflo) 12 VDC pump with AC adapter.

New Equipment:

On that screenshot

I started on this today and while at Lowe's picking up more things, the guy in electrical confused the crap out of me. He was saying that I needed a breaker before every device that's rated for said device. He also said that everything downstream should be matched (wire and breaker) for the upstream breaker. I was under the impression that everything downstream should be equal to OR LOWER than the breaker.

Here was my plan:

Home panel contains 50 amp breaker -->>8-3 wire-->> Spa Panel with 50 A GFCI (because 30 amp GFCI breaker itself cost way more -->> 8-3 wire-->> control panel.

From the spa panel to the control panel is a two-male ended 10/4 cored with L6-30 male plugs on it. This is my extension cord if you will.

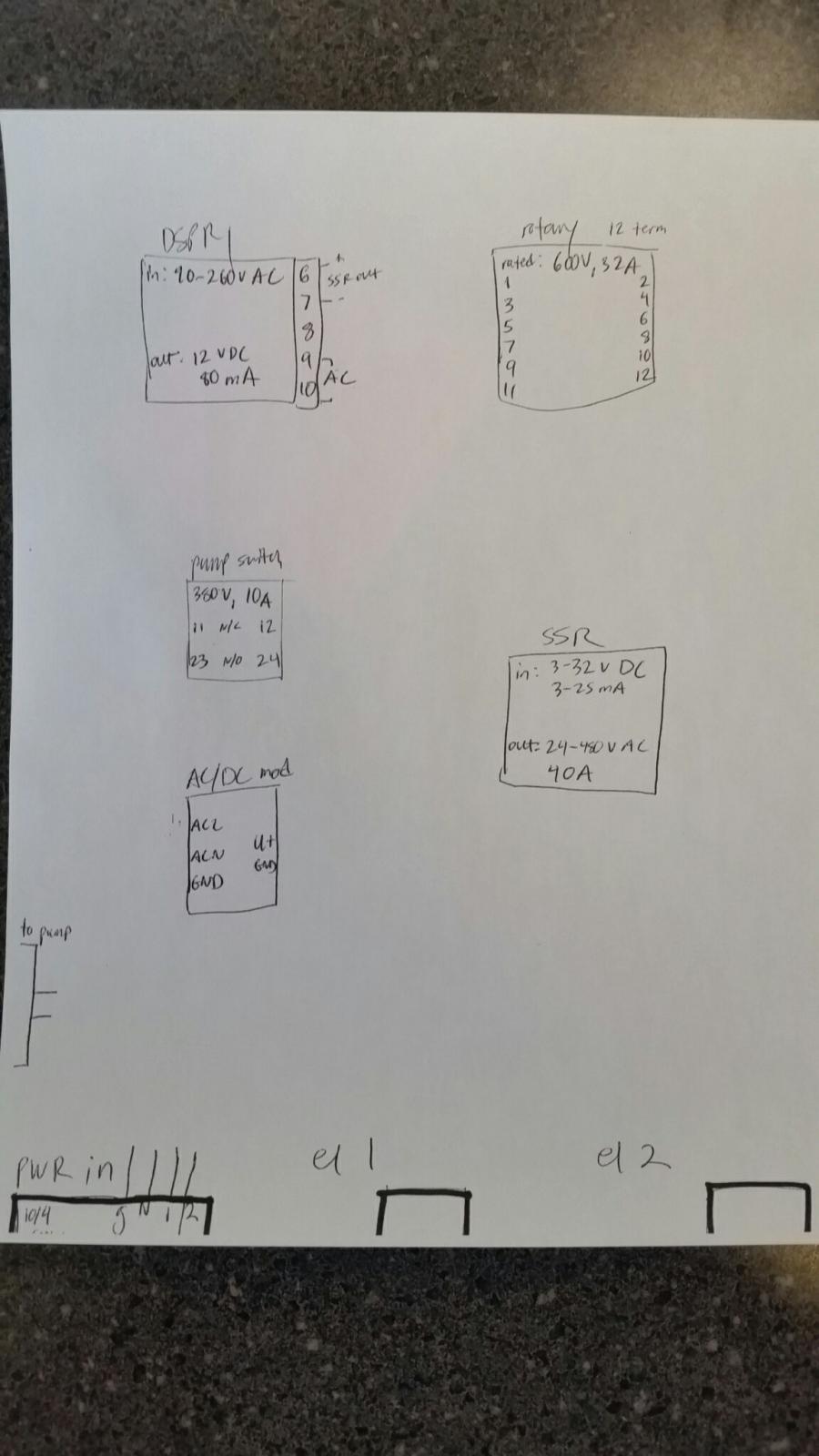

Control panel: input comes from the L6-30 receptacle > then goes into the 240 contactor with 120V coil > this provides power to the pump switch itself which is then going to the AC adapter which then goes to the pump AND to the SSVR and power meter which goes through the changeover switch into the element which is hardwired from the changeover to the female plug.

All the element stuff is with 10/4 wire, the pump with 14 gauge.

Notes: My elements are 5500W, so at peak it draws 23 amps, hence the 40 A SSVR for protection. I figure that a 40 A powered element under a 50 A GFCI is fine, yet the guy tells me I need a 40 A breaker in case more amperage finds it's way to the element. But I don't get it. It can only draw 23!!! no more will be sucked from it.

Also, for my pump he said to put a smaller breaker (like say 15 amp) before the pump. But again if it only draws 2 amps at 12 VDC (which will be downstream of the 120V AC adapter)...IDK now I'm confused.

My electrician buddy who helped me today said those breakers weren't needed, but he also said the contactor wasn't needed (the lowes guy didn't even know what a contactor was). I thought it was. How else will I get 4 wire from 3?

I feel like I'm missing a big "something" here. Can anyone help?

Here's what I have so far: