That the Lutra beer has a different hop characteristic than the Diamond batch fits with what I've read reported elsewhere - that kveik strains tend to mute hop characteristics a bit during fermentation. I can't say I've experienced this myself since 80% of the beers I brewed last year were malt-forward styles. Lutra made good beers with those. Perhaps I'll brew a split batch of West Coast IPA later this summer and compare Chico to Lutra and see when makes a better beer...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lager vs Kveik: The Test

- Thread starter Toxxyc

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I have the suspicion that it depends on the timing of the hop addition. My theory is that the yeast drops out together with the hop character forming molecules, it attracts them and then seals them in the sludge together with themselve.That the Lutra beer has a different hop characteristic than the Diamond batch fits with what I've read reported elsewhere - that kveik strains tend to mute hop characteristics a bit during fermentation. I can't say I've experienced this myself since 80% of the beers I brewed last year were malt-forward styles. Lutra made good beers with those. Perhaps I'll brew a split batch of West Coast IPA later this summer and compare Chico to Lutra and see when makes a better beer...

So I think that boil additions will differ vastly in terms of hop flavor and aroma from lutra to us05, while the effect of dry hopping, after the majority of the yeast already settled out, shouldn't be that different at all. My experience with lutra confirms this, I had really good hop flavour and aroma from short (2 days) and late dry hop additions.

I love your experiment, thank you for sharing such detailed tasting notes!! Above is about what I'd expected, as a very brief synopsis.the Lutra batch... It's fairly fruity, which I did not expect at all, so that's a very important thing I have to mention... The Diamond batch tasted like a green German Pilsner, which is what I made, but his Lutra batch almost tastes like a Pale Ale, which I guess it comes close to now.

Thank you OP for creating this thread! Excellent experiment that should be on Brulosophy.

Your early comments mirror my 'lager' experience with Lutra, which to me seems more like a clean Ale yeast than a pseudo-lager one. I actually really like Lutra, but I turn to other options when a real lager is needed. To me, Lutra could be a very nice option for a lot of clean ale styles, like a Blonde or a Pale Ale.

Your early comments mirror my 'lager' experience with Lutra, which to me seems more like a clean Ale yeast than a pseudo-lager one. I actually really like Lutra, but I turn to other options when a real lager is needed. To me, Lutra could be a very nice option for a lot of clean ale styles, like a Blonde or a Pale Ale.

Thank you OP for creating this thread! Excellent experiment that should be on Brulosophy.

Your early comments mirror my 'lager' experience with Lutra, which to me seems more like a clean Ale yeast than a pseudo-lager one. I actually really like Lutra, but I turn to other options when a real lager is needed. To me, Lutra could be a very nice option for a lot of clean ale styles, like a Blonde or a Pale Ale.

There was a more informal Bru Club article on Lutra vs 34/70. Spoiler: with a total of 51 tasters, the results were not-significant, but only 1 away (p=0.053 vs p=0.050).

https://brulosophy.com/2022/03/03/t...a-kveik-vs-saflager-w-34-70-in-a-german-pils/

I have never brewed with Lutra. A friend split a batch with Lutra (fermented warm) and another lager yeast (not sure which one, fermented with a traditional schedule). When I first tried the Lutra one, which was on tap quickly, I thought it was very nice. When the "real" lager was ready, the two beer were very different in a side by side. The Lutra was a bit too plain and lifeless, where the lager felt like a really solid lager type beer with more flavor and mouthfeel.

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

There was a more informal Bru Club article on Lutra vs 34/70. Spoiler: with a total of 51 tasters, the results were not-significant, but only 1 away (p=0.053 vs p=0.050).

https://brulosophy.com/2022/03/03/t...a-kveik-vs-saflager-w-34-70-in-a-german-pils/

I have never brewed with Lutra. A friend split a batch with Lutra (fermented warm) and another lager yeast (not sure which one, fermented with a traditional schedule). When I first tried the Lutra one, which was on tap quickly, I thought it was very nice. When the "real" lager was ready, the two beer were very different in a side by side. The Lutra was a bit too plain and lifeless, where the lager felt like a really solid lager type beer with more flavor and mouthfeel.

I would also have to say using a 32 ibu beer would not be a good test for tasting yeast differences. If anything I'd shoot for something in the 15-16 ibu range and something in the 1.038-1.040 range. Give it a fair shot. From experience Lutra tastes nothing like W34/70. Now here's the thing...I say that but some may prefer Lutra over 34/70 and that's ok. Some times it's so easy to get caught up in being right/wrong than accepting it's ok to have a different perspective lol I've been extremely guilty of that. Anywho at the end of the day brew what makes you happy!

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

The lower the og, the lower the yeast expression. Something in the range of 1.05 seems perfect to me. No muted expressions due to not many shorter sugars being available but also not too high to make things weired through elevated alcohol levels. 10 ibus less wouldn't have hurt though, but 32 is still not awfully high and as there are no huge dry or late additions included, I think it's a pretty good beer for this testI would also have to say using a 32 ibu beer would not be a good test for tasting yeast differences. If anything I'd shoot for something in the 15-16 ibu range and something in the 1.038-1.040 range. Give it a fair shot. From experience Lutra tastes nothing like W34/70. Now here's the thing...I say that but some may prefer Lutra over 34/70 and that's ok. Some times it's so easy to get caught up in being right/wrong than accepting it's ok to have a different perspective lol I've been extremely guilty of that. Anywho at the end of the day brew what makes you happy!

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

The lower the og, the lower the yeast expression. Something in the range of 1.05 seems perfect to me. No muted expressions due to not many shorter sugars being available but also not too high to make things weired through elevated alcohol levels. 10 ibus less wouldn't have hurt though, but 32 is still not awfully high and as there are no huge dry or late additions included, I think it's a pretty good beer for this test

Mind providing a source on the muted expressions or is this just a personal experience that's been had? I've not run into this, but, again that's just my experience

I havebrewed quite a lot of low abv beers and the lower I got the lower the yeast expression got. It got to a point were it didn't basically matter any more if it would have been an american ale yeast or an english yeast as the difference was really low. It is actully quite a logical thing, the yeast expression is a result of yeast metabolism. The lower the amount of sugars to metabolize, the lower the resulting yeast expression. It can be manipulated a bit by changing the type of sugars towards the shorter sugars, as these tend to result in stronger ester production, but overall, the less sugars, the less metabolisation, the less yeast expression.Mind providing a source on the muted expressions or is this just a personal experience that's been had? I've not run into this, but, again that's just my experience

Toxxyc

New and loving it

Yeah that's why with this test I decided to boost my ABV and OG a little bit. I typically make 1.042~ish beers, that's my favourite spot for OG, which then ferments down to 1.008-ish. I mashed this beer about 3 degrees warmer than I usually do on my thermometers (I love mashing at 63°C, this was mashed at 66°C), which I guess shows in the 2 gravity points higher FG. I did the 1.050 gravity (I actually aimed for 1.052) to give the yeast a bit more to chew on, and it seems to have done the trick.

I have 6 or 7 bottles in a box in the cupboard with a heat blanket on them now to see how they carbonate. I'll also be doing a room temp vs cold conditioning test on two of these bottles, similar to the video currently on my YT channel, but an updated one with a bit more brewing below my belt. But that's for later.

I have 6 or 7 bottles in a box in the cupboard with a heat blanket on them now to see how they carbonate. I'll also be doing a room temp vs cold conditioning test on two of these bottles, similar to the video currently on my YT channel, but an updated one with a bit more brewing below my belt. But that's for later.

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,461

There's an interesting theory that yeast (ester) profiles are the result of overflow of the right kind of metabolism and yeast ester production can be controlled by the brewer manipulating the fermentation process. Rather than low gravity worts, per se, I've found promoting the wrong kind of metabolism subdues otherwise noticeable yeast profiles in low gravity English ales. But these beers are best consumed fresh, as they tend to get bland over time. Pressure, even from an airlock, risks a bland beer. So does pitching poor quality yeast, which take days for fermentation to start then proceed slowly by the skin of their teeth. Insufficient aeration. Dry yeast, too, imho. I think the idea is to promote fermentation (ester overflow) then tweak it to obtain a balanced yeast profile. At least one that the brewer likes. If it's not working, try another yeast strain. Eventually, a Yorkshire ale strain is going to be chosen for English ales

That sounds quite possible, except for air lock pressure.There's an interesting theory that yeast (ester) profiles are the result of overflow of the right kind of metabolism and yeast ester production can be controlled by the brewer manipulating the fermentation process. Rather than low gravity worts, per se, I've found promoting the wrong kind of metabolism subdues otherwise noticeable yeast profiles in low gravity English ales. But these beers are best consumed fresh, as they tend to get bland over time. Pressure, even from an airlock, risks a bland beer. So does pitching poor quality yeast, which take days for fermentation to start then proceed slowly by the skin of their teeth. Insufficient aeration. Dry yeast, too, imho. I think the idea is to promote fermentation (ester overflow) then tweak it to obtain a balanced yeast profile. At least one that the brewer likes. If it's not working, try another yeast strain. Eventually, a Yorkshire ale strain is going to be chosen for English ales

We have to get rid of this myth. The pressure that is generated through a filled air lock on the yeast in suspension is the equal amount of pressure that would be generated by filling the fermenter about 2cm higher with wort (I am an hydraulic engineer so I know a bit about this topic).

Nobody would say that filling a fermenter 2cm higher results in ester surpression.

BUT, and there you are probably right, what does happen is that the unfilled air lock let's in oxygen and that little additional oxygen changes the metabolic pathways used by the yeast towards more expressive pathways.

That is probably the reason why open fermentation of English ales (at least for the first few days) leads to different results than the completely anaerobic fermentation under an air lock.

With saison yeasts this little additional oxygen seems to boost the enzyme expression used for the diastetic nature of most of these yeasts. A lack of oxygen during the first few days results with sensitive strains in a saison stall, open fermentation for the first few days seems to solve this issue plus boosts yeast expression. In my experiments, this worked out well.

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,461

I don"t think it has much to do with oxygen whilst there's positive pressure involved, why an airlock is very useful when fermentation winds down. Even the slightest back pressure increases CO2 levels inside the FV and wort. From a yeast's perspective, it changes behaviour causing increased rates of foaming, which leads to mess and loss of yeast. Not all airlocks are equal, though. I've some BetterBottle dry airlocks that have a tiny glass sphere (weighing bugger all) that seal things and some big chunky Speidel airlocks, which I quite like, which promote more back pressure, relatively speaking, and more than enough to alter the behaviour of top-cropping yeast. Even my best lagers have been fermented 'open', without an airlock. Although foaming isn't usually a problem with lager yeast CO2 is a yeast stress factor. I suspect yeast cells monitor CO2 levels to make biological decisions that limit population growth.That sounds quite possible, except for air lock pressure.

We have to get rid of this myth. The pressure that is generated through a filled air lock on the yeast in suspension is the equal amount of pressure that would be generated by filling the fermenter about 2cm higher with wort (I am an hydraulic engineer so I know a bit about this topic).

Nobody would say that filling a fermenter 2cm higher results in ester surpression.

BUT, and there you are probably right, what does happen is that the unfilled air lock let's in oxygen and that little additional oxygen changes the metabolic pathways used by the yeast towards more expressive pathways.

That is probably the reason why open fermentation of English ales (at least for the first few days) leads to different results than the completely anaerobic fermentation under an air lock.

With saison yeasts this little additional oxygen seems to boost the enzyme expression used for the diastetic nature of most of these yeasts. A lack of oxygen during the first few days results with sensitive strains in a saison stall, open fermentation for the first few days seems to solve this issue plus boosts yeast expression. In my experiments, this worked out well.

You have to believe me, as long as there's water involved, the maximum back pressure generated by an air lock is equal to the water hight in the air lock. Does not matter how it is build.I don"t think it has much to do with oxygen whilst there's positive pressure involved, why an airlock is very useful when fermentation winds down. Even the slightest back pressure increases CO2 levels inside the FV and wort. From a yeast's perspective, it changes behaviour causing increased rates of foaming, which leads to mess and loss of yeast. Not all airlocks are equal, though. I've some BetterBottle dry airlocks that have a tiny glass sphere (weighing bugger all) that seal things and some big chunky Speidel airlocks, which I quite like, which promote more back pressure, relatively speaking, and more than enough to alter the behaviour of top-cropping yeast. Even my best lagers have been fermented 'open', without an airlock. Although foaming isn't usually a problem with lager yeast CO2 is a yeast stress factor. I suspect yeast cells monitor CO2 levels to make biological decisions that limit population growth.

You wouldn't say that filling up your fermenter two cm higher would change ester expression, would you? That's what an air lock does, it generates additional pressure equal to the water height in itself, which is usually only one or two cm.

Positive pressure does not mean that no oxygen gets inside, the effect that Henry's law describes takes care of that.

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,461

It changes the behaviour of top-cropping yeast and I prefer open fermented beers. That's all I'm saying.You wouldn't say that filling up your fermenter two cm higher would change ester expression, would you?

Not all FV walls, taps and other 'sealed' openings are impermeable to O2, of course, but O2 entering via the point of off-gasing is limited by basic physics of mass movement in one direction, out of the active FV. I'm not sure if Henry covered that bit, no pun intendedPositive pressure does not mean that no oxygen gets inside, the effect that Henry's law describes takes care of that.

I understand your reasoning regarding the oxygen inflow against the off-gassing direction. However, you would be surprised how much turbulences are happening within the flow through openings, that's not a laminar structure at all. So there's always some counter direction mixing involved.It changes the behaviour of top-cropping yeast and I prefer open fermented beers. That's all I'm saying.

Not all FV walls, taps and other 'sealed' openings are impermeable to O2, of course, but O2 entering via the point of off-gasing is limited by basic physics of mass movement in one direction, out of the active FV. I'm not sure if Henry covered that bit, no pun intendedFermenting wort is far from an inert, ideal solution simple to model. There's a lot of biology going on in that stuff. Letting the esters overflow isn't a bad idea

And as soon as we got a bigger opening and not only an empty air lock, the flow speed becomes so small, it doesn't make any difference any more.

If the behaviour of top cropping yeast changes, the reason is not the pressure, there must be something else. The pressure difference between air lock and no air lock is so small, it is completely neglectable (is that a word?).

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,461

It's most likely a pressure induced increase in CO2 levels in the fermenting wort that increases the rate of foaming. Top-cropping brewer's yeast practice CO2 powered floating to an extreme, by brewer's yeast standards. CO2 is what makes active yeast bouyant generally. Top-croppers seem to have taken it to another level. The difference in behaviour is easily observable, just remove or add an airlock. Even in a starter. The pressure difference might seem small (or negligible) to us, but, for yeast, it's enough to elicit behavioural changes.If the behaviour of top cropping yeast changes, the reason is not the pressure, there must be something else. The pressure difference between air lock and no air lock is so small, it is completely neglectable (is that a word?).

VikeMan

It ain't all burritos and strippers, my friend.

- Joined

- Aug 24, 2010

- Messages

- 5,966

- Reaction score

- 6,216

I've brewed several beers with Lutra. It is quickly becoming my house ale yeast. Being an ale yeast, it does not consume the same sugars that lager yeasts do so it will never have the "crisp" flavor note of a lager. I've never had a problem with my Lutra beers dropping clear and have brewed several at room temp that dropped clear enough in ten days that I could read the paper through it.

When I brew with Lutra (or Voss), I usually pitch it at room temp (~23°C) and let it ride. Lutra has not made a disappointing beer for me yet.

All kveik strains I've brewed with require some conditioning time in the keg. Lutra less than others but still, a couple weeks.

The idea that lager crispness is because lager yeast eat sugars that ale yeasts don't is a little misleading, IMO. It may be true that "on average" lager yeasts are more attenuative, but it's not universal. I think the notion sometimes comes from the fact that lager strains can ferment raffinose and melibiose. This fact is quite true, but also not really relevant, because they are either absent from beer wort or present in only in insignificant amounts. A breakdown of what species use what sugars:

- Glucose: Ale and Lager, virtually 100% attenuation

- Fructose: Ale and Lager, virtually 100% attenuation

- Sucrose: Ale and Lager, virtually 100% attenuation

- Maltose: Ale and Lager, virtually 100% attenuation

- Maltotriose: Specific Strain dependent, but both Ale and Lager strains use it, to various extents. It's the strain and not the species per se that matters for Maltotriose, which is the big driver of attenuation differences between strains.

(- Raffinose: Lager Strains Only (but not significant in beer))

(- Melibiose: Lager Strains Only (but not significant in beer))

VikeMan

It ain't all burritos and strippers, my friend.

- Joined

- Aug 24, 2010

- Messages

- 5,966

- Reaction score

- 6,216

There was a more informal Bru Club article on Lutra vs 34/70. Spoiler: with a total of 51 tasters, the results were not-significant, but only 1 away (p=0.053 vs p=0.050).

https://brulosophy.com/2022/03/03/t...a-kveik-vs-saflager-w-34-70-in-a-german-pils/

"While 24 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 23 did (p=0.053), indicating participants in this xBmt were unable to reliably distinguish a German Pils fermented with Omega Yeast OYL-071 Lutra Kveik at 66°F/19°C from one fermented with Saflager W-34/70 at 52°F/11°C."

Jeez. According the the numbers, if there were no detectable difference between these beers, there was only a 5.3 percent chance that 23 or more of the tasters would make the correct choice. But they did. I'd feel pretty good about betting a paycheck on "they tasted a real difference." But "indicating participants in this xBmt were unable to reliably distinguish" fits the usual "nothing matters" narrative.

It might be, but I doubt it. Let's assume that the pressure somehow increases co2 levels in the liquid, this means that the off-gassing would be slowed down until the higher limit of dissolved co2 has been reached, which would be almost instantly as co2 is constantly excreted by the yeast in big amounts. Once this limit has been reached, off-gassing, ie bubbles, would form in the same manner as it would without the additional pressure of the air lock. It's a bit like a container with two openings. Through the first opening, water gets pumped in. Once it's full, through the other opening the same amount flows out that gets pumped into it. Once you increase the size of the container, it only affects the outgoing flow up until it is full again. From then, same output as before.It's most likely a pressure induced increase in CO2 levels in the fermenting wort that increases the rate of foaming. Top-cropping brewer's yeast practice CO2 powered floating to an extreme, by brewer's yeast standards. CO2 is what makes active yeast bouyant generally. Top-croppers seem to have taken it to another level. The difference in behaviour is easily observable, just remove or add an airlock. Even in a starter. The pressure difference might seem small (or negligible) to us, but, for yeast, it's enough to elicit behavioural changes.

Or do you mean that the slightly increased co2 concentration within the liquid somehow affects the metabolism of the yeast and not the bubbles the kräusen?

If that would be the case, atmospheric pressure changes would affect the brew even stronger, these pressure differences are bigger. Or brewing at an altitude.... Mt Everest English ester bomb? Who knows

Last edited:

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,461

Now you're just gasing offIt might be, but I doubt it. Let's assume that the pressure somehow increases co2 levels in the liquid, this means that the off-gassing would be slowed down until the higher limit of dissolved co2 has been reached, which would be almost instantly as co2 is constantly excreted by the yeast in big amounts. Once this limit has been reached, off-gassing, ie bubbles, would form in the same manner as it would without the additional pressure of the air lock. It's a bit like a container with two openings. Through the first opening, water gets pumped in. Once it's full, through the other opening the same amount flows out that gets pumped into it. Once you increase the size of the container, it only affects the outgoing flow up until it is full again. From then, same output as before.

Hahaha, I just added something while you were typing an answer. I'm a rock climbing yeast nowNow you're just gasing offYou've got to stop thinking like a squishy human bean and start viewing the world like a yeast.

Homebrew Harry

Well-Known Member

- Joined

- Jul 25, 2021

- Messages

- 387

- Reaction score

- 397

Has anyone ever tried to ferment a human bean ?Now you're just gasing offYou've got to stop thinking like a squishy human bean and start viewing the world like a yeast.

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,461

It wouldn't surprise my if one of those 'orrible giants tried fermenting squishy human beans. Except that big friendly one. He only fermented snozzcumbers.Has anyone ever tried to ferment a human bean ?

Toxxyc

New and loving it

I fully agree. This is actually something this test of mine will also address - I brewed one wort, split it and fermented it with two yeasts. So the wort I fed to the two yeasts is identical in every possible way the word can be interpreted, because it's the same wort, same batch.The idea that lager crispness is because lager yeast eat sugars that ale yeasts don't is a little misleading, IMO. It may be true that "on average" lager yeasts are more attenuative, but it's not universal. I think the notion sometimes comes from the fact that lager strains can ferment raffinose and melibiose. This fact is quite true, but also not really relevant, because they are either absent from beer wort or present in only in insignificant amounts. A breakdown of what species use what sugars:

- Glucose: Ale and Lager, virtually 100% attenuation

- Fructose: Ale and Lager, virtually 100% attenuation

- Sucrose: Ale and Lager, virtually 100% attenuation

- Maltose: Ale and Lager, virtually 100% attenuation

- Maltotriose: Specific Strain dependent, but both Ale and Lager strains use it, to various extents. It's the strain and not the species per se that matters for Maltotriose, which is the big driver of attenuation differences between strains.

(- Raffinose: Lager Strains Only (but not significant in beer))

(- Melibiose: Lager Strains Only (but not significant in beer))

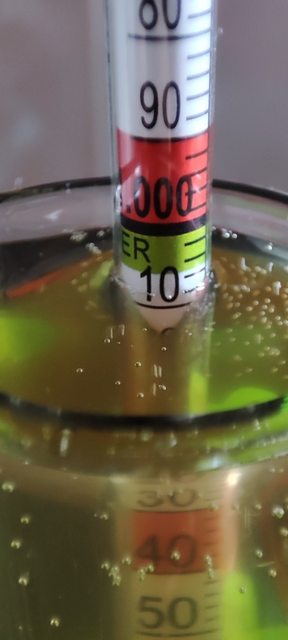

I still got the exact same FG from both yeasts - one being a cold lager yeast fermented at 10°C and the other being a hot ale yeast fermented at 25°C. Both started at 1.050 and ended at 1.010 for an identical attenuation of 79%. And I spent a lot of time on getting the absolute perfect hydrometer readings for both, trust me. I spend a good 20 minutes with each test tube, stirring and getting the CO2 out of there, heating it up to release more CO2 and to get the temperature to 20°C, using the same thermometer to measure both samples to the same temperature. I even had the hydrometers floating in the test tube, where I took a reading, and then I filled it up more (added little stones to boost the beer level in the tube) so I could measure on the meniscus at the top of the tube. I took pictures and between the two I can't see a realistic difference in the readings. If I had to say, I'd have to guess there's a 0.0025 difference between the two, but that can be attributed to carbonation or even temperature difference under 1°C between the two batches. Proof:

This is the Diamond Lager's FG reading at 20°C:

This is the Omega Kveik Lutra's FG reading at 20°C:

So I'll have to say that if the lager batch in this test is more "crisp" than the ale yeast, there's something else at play, it's definitely not the FG making the difference here.

Toxxyc

New and loving it

OK so the bottled beers seem to be flocculating already, so I'm guessing the carb drops have been eaten up and the yeast are settling down. I moved one into the fridge to see if it's where I want it, and if it's ready, I'll be moving all but one into the fridge as well tonight.

In 2 months' time I'll do a comparison video between the warm stored beer, and one of the cold stored beers.

In 2 months' time I'll do a comparison video between the warm stored beer, and one of the cold stored beers.

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,461

If the intention is to compare the different yeast then all other factors need to be controlled, including condition of the yeast, to make things comparable. Otherwise it's apples and oranges for several reasons. I can see several potentially confounding factors in your comparison, which risk invalidating conclusions about any differences being due to yeast strain. Although I'm confident you'll prefer Diamond Lager yeast, regardless, if you want a lager.

Last edited:

One thing I just thought about, flocculation and completed consumption of carbonation sugars are not connected. There can still be plenty of sugar in solution while the yeast starts to drop out already.

I just made a Lutra starter and as usual by the time I got from the kitchen to the basement brewery the yeast had settled. I'm brewing a spruce tip IPA for the 4th and putting it in a pin. Because of how fast this yeast settles and the beer being so clear I'm adding 3 grams of CBC along with the sugar. I'm interested in the bottle carb on those samples.

Similar threads

- Replies

- 13

- Views

- 2K

- Replies

- 46

- Views

- 2K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)