fendersrule

Well-Known Member

- Joined

- Oct 11, 2018

- Messages

- 703

- Reaction score

- 342

I decided to do an all-grain 2-3 gallon batch using my hemp bag in one of my girlfriend's pots. I'll probably dunk sparge since it's all on a stove top, or just omit sparging all together and just raise my grain bill to assume 60% efficiency. I'm going to reserve my 20 gallon pots for serious batch sizes. I'll plan to use US-05 yeast by the end. Something about 6% ABV would fit the bill pretty well...we like our beers to have some kick in the pants.

What is a really dead simple sour recipe that we could pitch bacteria at 70F? I think it's best we not mess with fruits/flavorings this go around, just something to get our feet wet with a sour ale. Not looking for anything extravagant, just a simple grain bill that would make a good sour beer that's easier for her to try. I'd welcome a step-by-step guide. I don't test my water (yet), but I know that tap water tastes pretty good here...not the best, but my beers have been pretty impressionable in a good way.

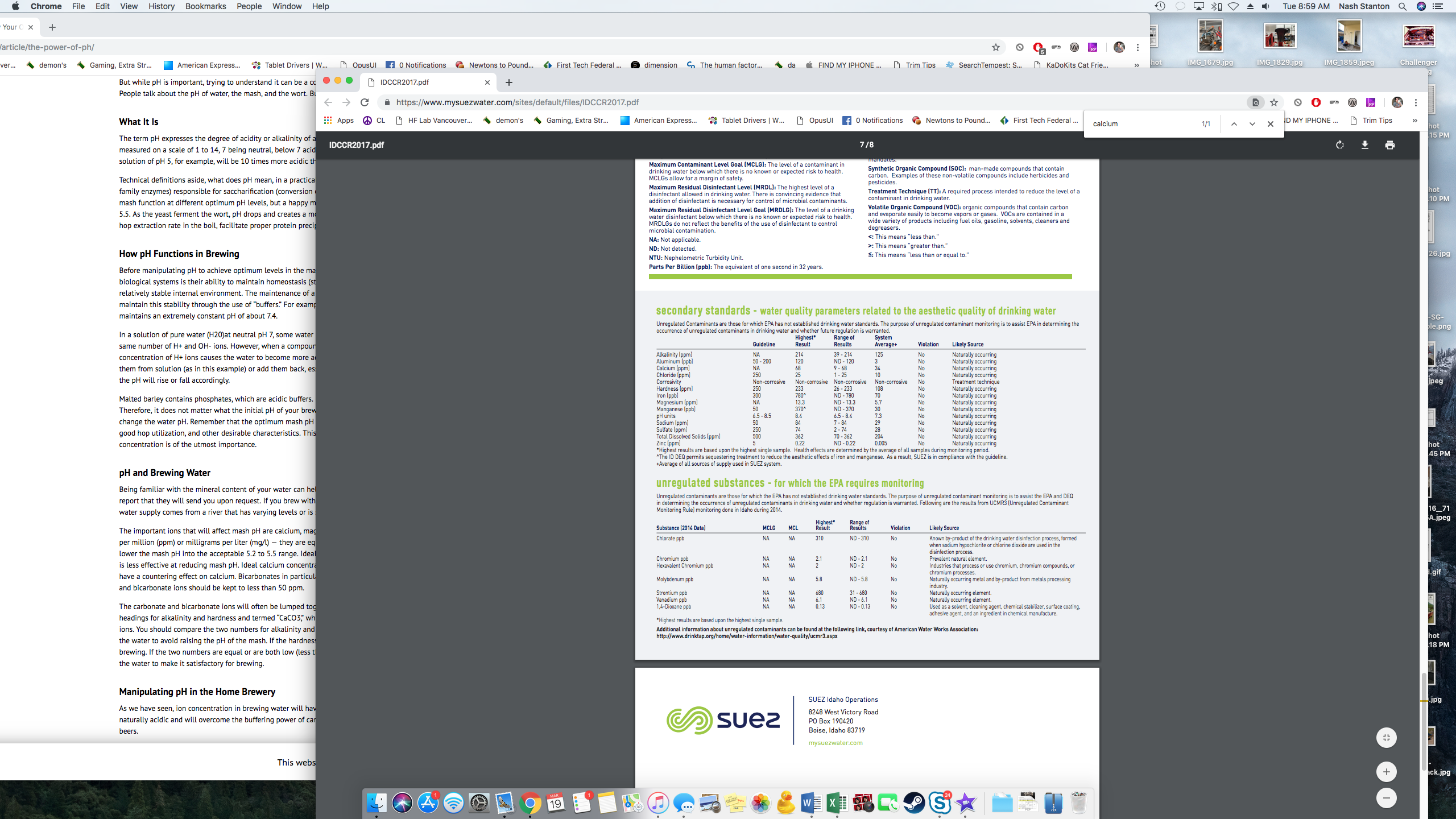

I looked at my city water report and my PH is "common" at 7.0 Ph. It's a little on the high side, but it's not bad. See below, which was from a couple years ago.

I'd welcome any hand-holding here. I'd take pics a long the way. The girlfriend wants to take a break from making her delicious ciders (they are VERY good), and wants to try a simple sour ale. The girlfriend LOVES the aroma of hops more than the "bitter" taste. She's hard to please, but as long as she tastes sour and smells hop aroma, she will be pleased. Help!

What is a really dead simple sour recipe that we could pitch bacteria at 70F? I think it's best we not mess with fruits/flavorings this go around, just something to get our feet wet with a sour ale. Not looking for anything extravagant, just a simple grain bill that would make a good sour beer that's easier for her to try. I'd welcome a step-by-step guide. I don't test my water (yet), but I know that tap water tastes pretty good here...not the best, but my beers have been pretty impressionable in a good way.

I looked at my city water report and my PH is "common" at 7.0 Ph. It's a little on the high side, but it's not bad. See below, which was from a couple years ago.

I'd welcome any hand-holding here. I'd take pics a long the way. The girlfriend wants to take a break from making her delicious ciders (they are VERY good), and wants to try a simple sour ale. The girlfriend LOVES the aroma of hops more than the "bitter" taste. She's hard to please, but as long as she tastes sour and smells hop aroma, she will be pleased. Help!

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)