Yep, I've been talking to him for about two years now I guess. I'm surprised he didn't connect the dots.Lee, Thomas from SwissFlo was kind enough to swap out their regular JG fittings for the 8mm ones when I purchased their flowmeters. If you buy the SF800 flowmeters, just ask if they can swap the fittings out--he said the cost differential was negligible. Thomas was curious about this Keg cop project too so I sent him the Homebrewing DIY podcast link.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Keg Cop: Keg Monitoring and Control

- Thread starter LBussy

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

kmllr315

Active Member

Hi all, as I’m patiently waiting for my various pieces to come through customs and elsewhere, can anyone please upload some pics of their board builds? I’m a very visual learner and really need the help with what goes where exactly for soldering. Or is this fairly self explanatory once I get all the pieces in hand? Thanks in advance!

I looked back through and I can't seem to find my pics. I thought I saved them but ...

I'd be happy to take any pics you'd like to see. Assuming I don't need to pull any kegs out.

I'd be happy to take any pics you'd like to see. Assuming I don't need to pull any kegs out.

kmllr315

Active Member

Thanks Lee! I’d love to see each of the boards if you can.I looked back through and I can't seem to find my pics. I thought I saved them but ...

I'd be happy to take any pics you'd like to see. Assuming I don't need to pull any kegs out.

Or is this fairly self explanatory once I get all the pieces in hand? Thanks in advance!

I am a neophyte when it comes to soldering and I successfully built the project. As that adage goes, if I can do it, anyone can. I followed the written instructions in the docs. I only had a couple of questions that @LBussy answered very quickly.

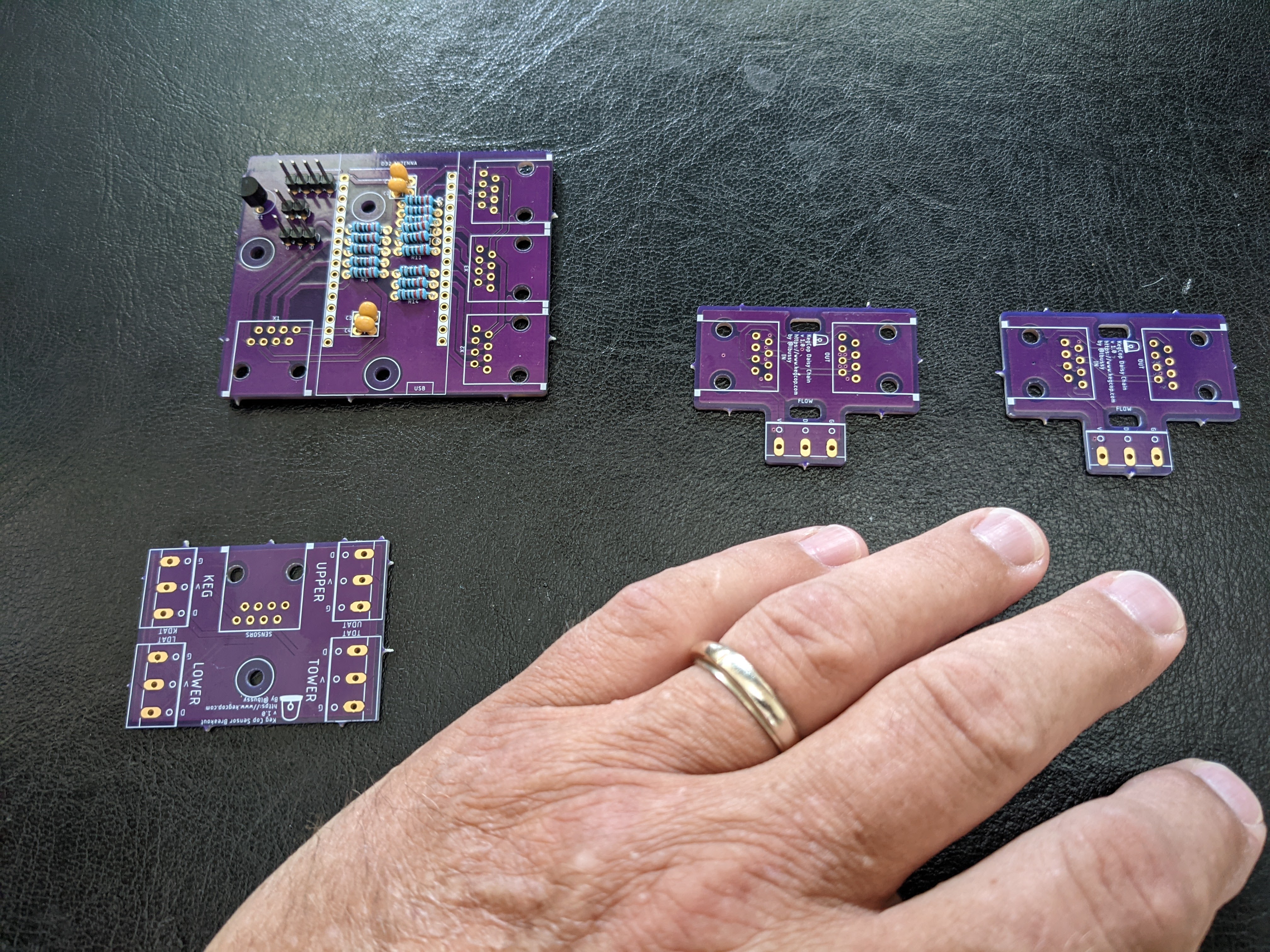

This is the only shot I have during the build

All that's left to install are screw terminals and RJ-45 jacks. You will note the onboard DS18B20 top-left of the main board. There is also a 3-pin header just to the right of it where you can connect a wired sensor. Lee's advice to me was to clip the onboard sensor and use an external one as heat from the relays would affect readings from the onboard sensor - assuming you are going to use the enclosure as outlined in the documents and room temperature is an important metric you want to track.

Hope that helps.

Cheers!

Thanks for posting those! You saved me some time.

The RJ45 jacks fit in all the boxes on the board having 8-holes. Then there's a handful of three-wire terminals on the break-out boards.

There's really not a lot on these boards. I tried very hard to make it simple and approachable. For instance, there are five resistors for each of the one-wires. More than a couple of people have asked "why not use one-wire like it's supposed to be done and use one wire?!" Well, if you use BrewPi or any of the derivatives, one of the "fiddly" things is you need to determine which sensor is which. Well, let me ask you: Would you rather call a sensor "Tower," or "28EED5641A1602EC?"

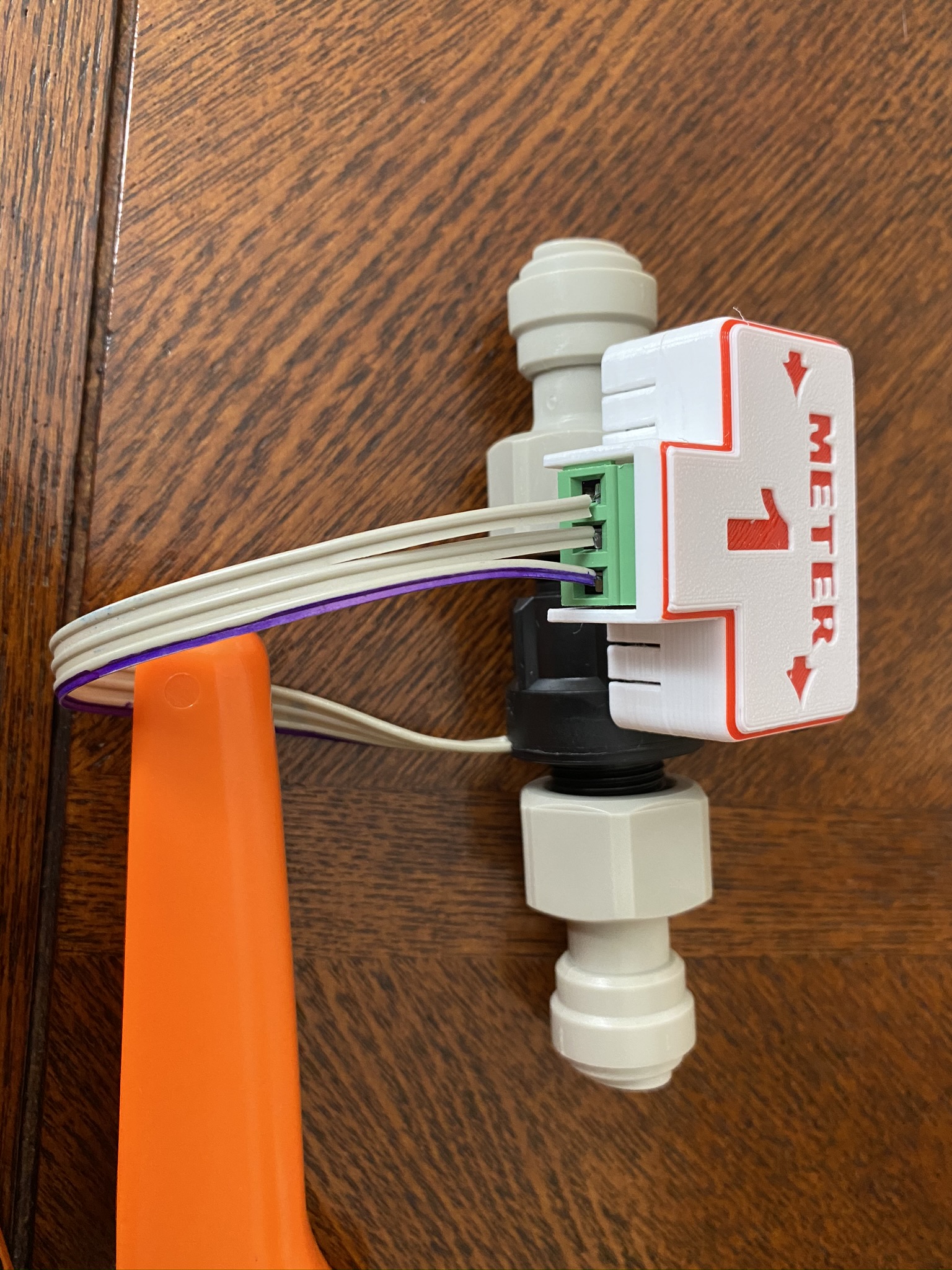

The daisy-chain breakouts (the "T" shaped boards) are pretty simple. There are no electronic pieces on them, only connectors. Two RJ45 and a three-wire terminal to connect the flowmeter.

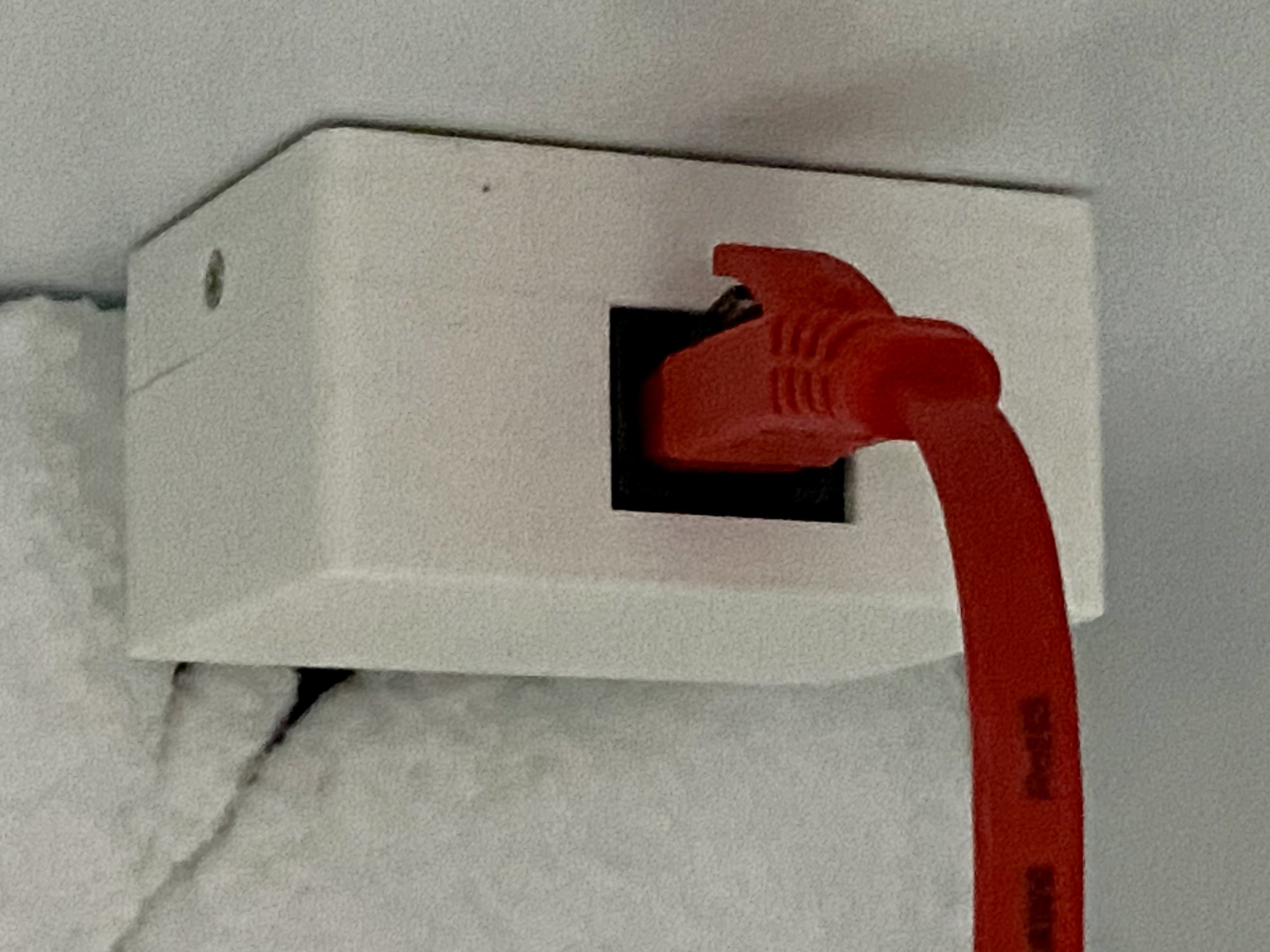

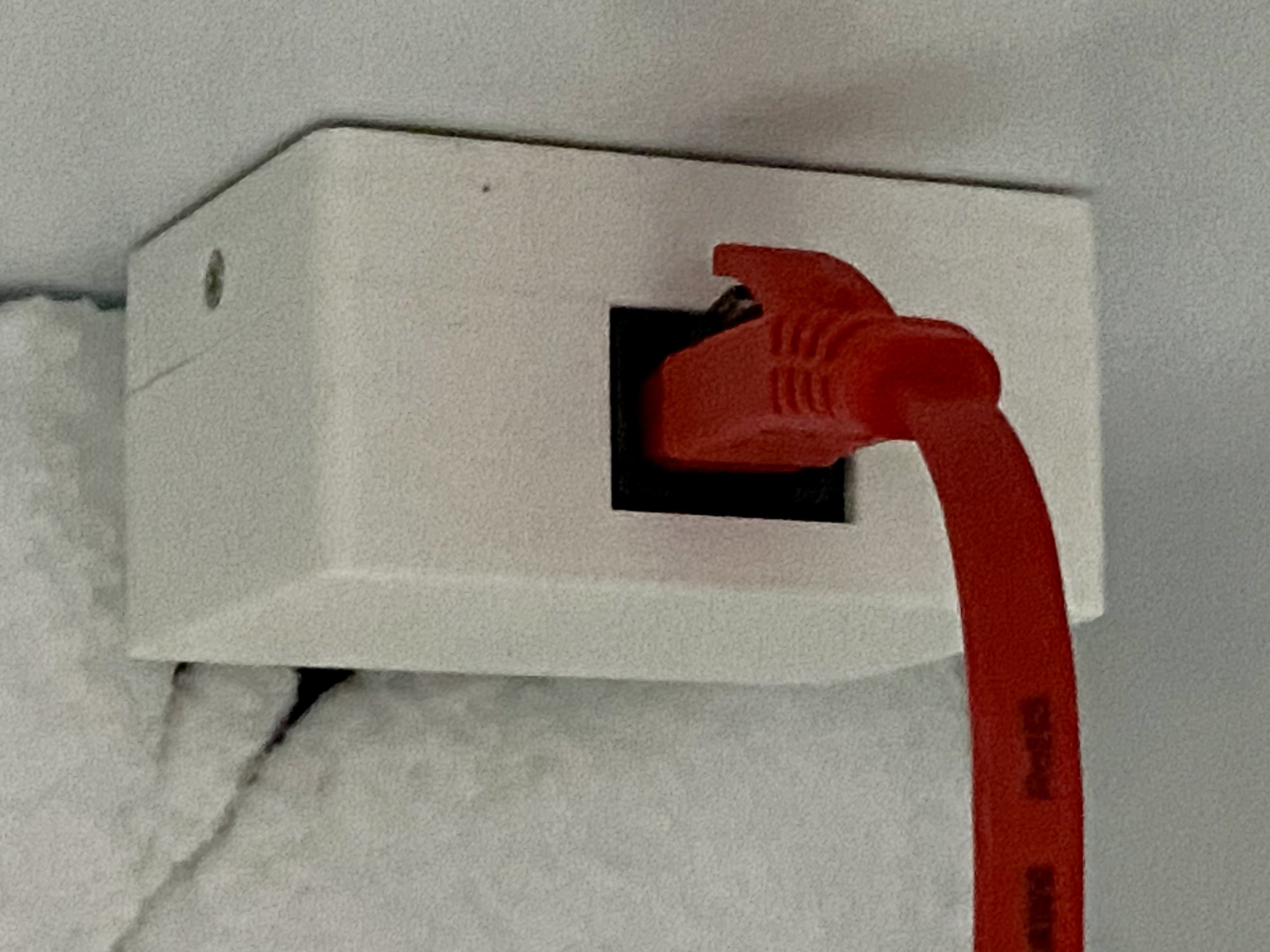

You can see the yellow ethernet cable come in the bottom and out the top of #1. The out from there goes into the in on #2, and so on. The 3D printed covers just clip on the boards and show the direction of the daisy-chain wiring. If you put them on in the right orientation it matches the liquid flow, but nothing forces that.

Pay no attention to the fact that I REALLY need to defrost my kegerator

Here's a working Keg Cop:

This is the temp sensor breakout in the 3D printed box. If my kegerator didn't need to be defrosted so badly, you would see the four one-wire leads coming out the back.

The RJ45 jacks fit in all the boxes on the board having 8-holes. Then there's a handful of three-wire terminals on the break-out boards.

There's really not a lot on these boards. I tried very hard to make it simple and approachable. For instance, there are five resistors for each of the one-wires. More than a couple of people have asked "why not use one-wire like it's supposed to be done and use one wire?!" Well, if you use BrewPi or any of the derivatives, one of the "fiddly" things is you need to determine which sensor is which. Well, let me ask you: Would you rather call a sensor "Tower," or "28EED5641A1602EC?"

The daisy-chain breakouts (the "T" shaped boards) are pretty simple. There are no electronic pieces on them, only connectors. Two RJ45 and a three-wire terminal to connect the flowmeter.

You can see the yellow ethernet cable come in the bottom and out the top of #1. The out from there goes into the in on #2, and so on. The 3D printed covers just clip on the boards and show the direction of the daisy-chain wiring. If you put them on in the right orientation it matches the liquid flow, but nothing forces that.

Pay no attention to the fact that I REALLY need to defrost my kegerator

Here's a working Keg Cop:

- Power (for the kegerator) in

- Power out (through the relay)

- Room temperature sensor

- Temperature sensor cable (goes to breakout board)

- Controller power (5V)

- Flowmeter cable

This is the temp sensor breakout in the 3D printed box. If my kegerator didn't need to be defrosted so badly, you would see the four one-wire leads coming out the back.

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

Holy ice crystals, Batman!

... shup.

Notice how there are zero pictures of my kegerator......

I found some more pics, I really thought I had more.

Temp sensor breakout:

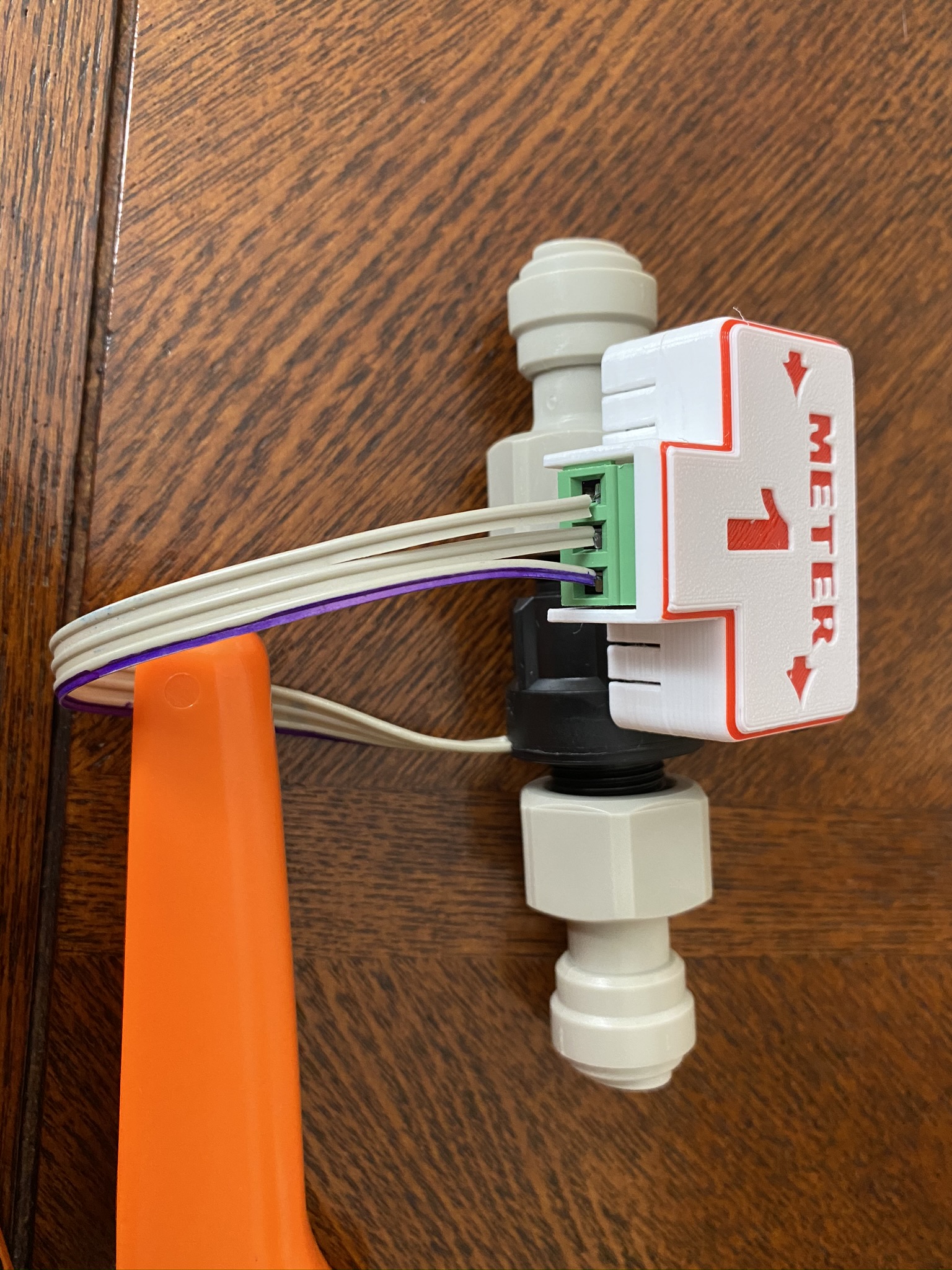

Flowmeter assembly:

Temp sensor breakout:

Flowmeter assembly:

I wish that my brother had used two filament colours when he printed my enclosures. I know you included that setup instruction in the package. Those look very cool, Lee.

Creality printers are coming down in pricing ... maybe I'll ask for one for Christmas ...

Creality printers are coming down in pricing ... maybe I'll ask for one for Christmas ...

kmllr315

Active Member

Thanks for all pictures, very helpful, am I missing the link to the 3-D printer files?I wish that my brother had used two filament colours when he printed my enclosures. I know you included that setup instruction in the package. Those look very cool, Lee.

Creality printers are coming down in pricing ... maybe I'll ask for one for Christmas ...

They might be on Lee's Github project page keg-cop/case at main · lbussy/keg-cop

I don't have a machine and have no idea what to look for but I bet he's loaded them there somewhere

Cheers!

I don't have a machine and have no idea what to look for but I bet he's loaded them there somewhere

Cheers!

Indeed - right here.

kmllr315

Active Member

Very nice, I’m not super experienced with 3D printing, how big of a printer do you need for these pieces? I’m guessing that the main board enclosure is the biggest?Indeed - right here.

My brother has one....it isn't very big at all. He built it from a kit about 8 years ago I think. He had no trouble printing these enclosures for me. I bought him a roll of PLA to compensate as, sadly, he doesn't like beer.

The main board enclosure is the largest at 90 x 127 x 32mm or 3.5 x 5 x 1.25 inches assembled. It's printed in two pieces. The temperature sensor enclosure is 57 x 45 x 32 and the flow meter is 38 x 51 x 19. I think that budget 3D printers can handle objects 220 x 220 x 250mm.

Cheers!

The main board enclosure is the largest at 90 x 127 x 32mm or 3.5 x 5 x 1.25 inches assembled. It's printed in two pieces. The temperature sensor enclosure is 57 x 45 x 32 and the flow meter is 38 x 51 x 19. I think that budget 3D printers can handle objects 220 x 220 x 250mm.

Cheers!

Just talked with my brother. His print bed is 180 x 180 x 200 mm.

Hope that helps.

Chris

Hope that helps.

Chris

rkhanso

Well-Known Member

- Joined

- Jan 24, 2017

- Messages

- 785

- Reaction score

- 178

I finally got the ESP32 from China. Put Keg Cop on it.

I know this not a very good test, other than connectivity - but when I ping the Keg Cop ESP32 and an ESP8266 I have on the network, I get very different ping times. Might there be something in the firmware that puts ICMP latency higher on the KegCop firmware? I've never used an ESP32 before.

Keg Cop ESP32:

ESP8266 for Fermentrack:

Or might this be an indication of some other problem? Or not a problem at all and I should just chill?

I know this not a very good test, other than connectivity - but when I ping the Keg Cop ESP32 and an ESP8266 I have on the network, I get very different ping times. Might there be something in the firmware that puts ICMP latency higher on the KegCop firmware? I've never used an ESP32 before.

Keg Cop ESP32:

Reply from 192.168.2.247: bytes=32 time=79ms TTL=255

Reply from 192.168.2.247: bytes=32 time=312ms TTL=255

Reply from 192.168.2.247: bytes=32 time=213ms TTL=255

Reply from 192.168.2.247: bytes=32 time=134ms TTL=255

Reply from 192.168.2.247: bytes=32 time=51ms TTL=255

Reply from 192.168.2.247: bytes=32 time=263ms TTL=255

Reply from 192.168.2.247: bytes=32 time=178ms TTL=255

Reply from 192.168.2.247: bytes=32 time=94ms TTL=255

Reply from 192.168.2.247: bytes=32 time=320ms TTL=255

Reply from 192.168.2.247: bytes=32 time=256ms TTL=255

Reply from 192.168.2.247: bytes=32 time=147ms TTL=255

Reply from 192.168.2.247: bytes=32 time=41ms TTL=255

Reply from 192.168.2.247: bytes=32 time=270ms TTL=255

Ping statistics for 192.168.2.247:

Packets: Sent = 830, Received = 829, Lost = 1 (0% loss),

Approximate round trip times in milli-seconds:

Minimum = 3ms, Maximum = 2276ms, Average = 172ms

Control-C

^C

C:\Users\Roger>^X

ESP8266 for Fermentrack:

Reply from 192.168.2.249: bytes=32 time=1ms TTL=128

Reply from 192.168.2.249: bytes=32 time=1ms TTL=128

Reply from 192.168.2.249: bytes=32 time=1ms TTL=128

Reply from 192.168.2.249: bytes=32 time=1ms TTL=128

Reply from 192.168.2.249: bytes=32 time=7ms TTL=128

Reply from 192.168.2.249: bytes=32 time=1ms TTL=128

Reply from 192.168.2.249: bytes=32 time=1ms TTL=128

Reply from 192.168.2.249: bytes=32 time=1ms TTL=128

Reply from 192.168.2.249: bytes=32 time=4ms TTL=128

Reply from 192.168.2.249: bytes=32 time=5ms TTL=128

Reply from 192.168.2.249: bytes=32 time=1ms TTL=128

Reply from 192.168.2.249: bytes=32 time=1ms TTL=128

Reply from 192.168.2.249: bytes=32 time=1ms TTL=128

Reply from 192.168.2.249: bytes=32 time=3ms TTL=128

Reply from 192.168.2.249: bytes=32 time=1ms TTL=128

Reply from 192.168.2.249: bytes=32 time=1ms TTL=128

Reply from 192.168.2.249: bytes=32 time=1ms TTL=128

Ping statistics for 192.168.2.249:

Packets: Sent = 110, Received = 109, Lost = 1 (0% loss),

Approximate round trip times in milli-seconds:

Minimum = 1ms, Maximum = 81ms, Average = 11ms

Control-C

^C

C:\Users\Roger>

Or might this be an indication of some other problem? Or not a problem at all and I should just chill?

I'm gonna go with "They all do that".

Here are five of my esp32s running light camera duty and their response times look every bit as random as yours

Pinging espcam1 [192.168.1.201] with 32 bytes of data:

Reply from 192.168.1.201: bytes=32 time=61ms TTL=255

Reply from 192.168.1.201: bytes=32 time=278ms TTL=255

Reply from 192.168.1.201: bytes=32 time=182ms TTL=255

Reply from 192.168.1.201: bytes=32 time=90ms TTL=255

Pinging espcam2 [192.168.1.202] with 32 bytes of data:

Reply from 192.168.1.202: bytes=32 time=139ms TTL=255

Reply from 192.168.1.202: bytes=32 time=57ms TTL=255

Reply from 192.168.1.202: bytes=32 time=279ms TTL=255

Reply from 192.168.1.202: bytes=32 time=189ms TTL=255

Pinging espcam4 [192.168.1.204] with 32 bytes of data:

Reply from 192.168.1.204: bytes=32 time=139ms TTL=255

Reply from 192.168.1.204: bytes=32 time=34ms TTL=255

Reply from 192.168.1.204: bytes=32 time=248ms TTL=255

Reply from 192.168.1.204: bytes=32 time=164ms TTL=255

Pinging espcam7 [192.168.1.207] with 32 bytes of data:

Reply from 192.168.1.207: bytes=32 time=100ms TTL=255

Reply from 192.168.1.207: bytes=32 time=96ms TTL=255

Reply from 192.168.1.207: bytes=32 time=113ms TTL=255

Reply from 192.168.1.207: bytes=32 time=119ms TTL=255

Pinging espcam8 [192.168.1.208] with 32 bytes of data:

Reply from 192.168.1.208: bytes=32 time=180ms TTL=255

Reply from 192.168.1.208: bytes=32 time=198ms TTL=255

Reply from 192.168.1.208: bytes=32 time=217ms TTL=255

Reply from 192.168.1.208: bytes=32 time=17ms TTL=255

All of my 8266s are used for BT/Serial bridges, ain't gonna get no ping responses from them ever...

Cheers!

Here are five of my esp32s running light camera duty and their response times look every bit as random as yours

Pinging espcam1 [192.168.1.201] with 32 bytes of data:

Reply from 192.168.1.201: bytes=32 time=61ms TTL=255

Reply from 192.168.1.201: bytes=32 time=278ms TTL=255

Reply from 192.168.1.201: bytes=32 time=182ms TTL=255

Reply from 192.168.1.201: bytes=32 time=90ms TTL=255

Pinging espcam2 [192.168.1.202] with 32 bytes of data:

Reply from 192.168.1.202: bytes=32 time=139ms TTL=255

Reply from 192.168.1.202: bytes=32 time=57ms TTL=255

Reply from 192.168.1.202: bytes=32 time=279ms TTL=255

Reply from 192.168.1.202: bytes=32 time=189ms TTL=255

Pinging espcam4 [192.168.1.204] with 32 bytes of data:

Reply from 192.168.1.204: bytes=32 time=139ms TTL=255

Reply from 192.168.1.204: bytes=32 time=34ms TTL=255

Reply from 192.168.1.204: bytes=32 time=248ms TTL=255

Reply from 192.168.1.204: bytes=32 time=164ms TTL=255

Pinging espcam7 [192.168.1.207] with 32 bytes of data:

Reply from 192.168.1.207: bytes=32 time=100ms TTL=255

Reply from 192.168.1.207: bytes=32 time=96ms TTL=255

Reply from 192.168.1.207: bytes=32 time=113ms TTL=255

Reply from 192.168.1.207: bytes=32 time=119ms TTL=255

Pinging espcam8 [192.168.1.208] with 32 bytes of data:

Reply from 192.168.1.208: bytes=32 time=180ms TTL=255

Reply from 192.168.1.208: bytes=32 time=198ms TTL=255

Reply from 192.168.1.208: bytes=32 time=217ms TTL=255

Reply from 192.168.1.208: bytes=32 time=17ms TTL=255

All of my 8266s are used for BT/Serial bridges, ain't gonna get no ping responses from them ever...

Cheers!

rkhanso

Well-Known Member

- Joined

- Jan 24, 2017

- Messages

- 785

- Reaction score

- 178

OK. I'll chalk my ESP8266s up as "Super-Controllers" since they respond usually at 1ms or so. Everything on the same WiFi network/SSID.

Ping time info is erased from my memory.

Now looking for a Swissflow meter.

I'm pumped up to get this project done.

Ping time info is erased from my memory.

Now looking for a Swissflow meter.

I'm pumped up to get this project done.

The ESP8266 handles interrupts very differently, the scheduling is completely changed between the two. While those times sorts suck, it's not like you are going to depend on network performance for flowmeter performance. I would chuck it in the * it bucket and keep going

rkhanso

Well-Known Member

- Joined

- Jan 24, 2017

- Messages

- 785

- Reaction score

- 178

If I can't pick up a Swissflow meter from someone in the US and save on shipping, would this flow meter be acceptable? I only thought it might work better because the flow is rated for 1L/min and if it's running at closer to the max capacity I thought it might be more accurate. It says .1-1.2L/min (with "1% repeat Error Drinking") - whatever that is. Unless 1L/min is too low (which I'm now thinking it might be).

I see many people are using the Swissflow meters. Has anyone had success choosing something less costly?

I see many people are using the Swissflow meters. Has anyone had success choosing something less costly?

Last edited:

I don't know of anyone in the US selling them new. It will work, and Keg Cop will allow you to calibrate to the proper pulse rate.If I can't pick up a Swissflow meter from someone in the US and save on shipping, would this flow meter be acceptable?

Not better, definitely not more accurate.I only thought it might work better because the flow is rated for 1L/min and if it's running at closer to the max capacity I thought it might be more accurate.

Well, do you want to stand there taking 30 seconds to pour a beer? Generally, 10 seconds for a point is a good pour rate. There is a class that does 0.5l - 6.0l that seems reasonable.Unless 1L/min is too low (which I'm now thinking it might be).

The whole point was to support nearly any flowmeter using 5v excitation and a pulse signal. There are more than a few people using lesser-priced flowmeters and they generally like them okay. I don't know of anyone who has SwissFlow That wants to change.

DaveS

Well-Known Member

Firstly, many thanks to @LBussy for sharing this really cool project (pun intended!)

Are wondering if there is any chance of load cell integration into keg cop,possibly using HX711 amplifier,instead of flow meters ?

Also,what are your thoughts regarding using load cells for keg monitoring ?

People complain of drift over time,could this be due to some load cells having an aluminium frame which could be distorting over time ?

Cheers

Are wondering if there is any chance of load cell integration into keg cop,possibly using HX711 amplifier,instead of flow meters ?

Also,what are your thoughts regarding using load cells for keg monitoring ?

People complain of drift over time,could this be due to some load cells having an aluminium frame which could be distorting over time ?

Cheers

Yes but no.

The firmware is getting pretty cramped, especially when I have to build in debug mode. I have poked around at load cells and I think I can re-use a bunch of the code, but adding it as a configuration item may be a step too far. I have some of it done, but my free time has been sucked up here lately.

WRT drift - yes, I've got some plans for that.

The firmware is getting pretty cramped, especially when I have to build in debug mode. I have poked around at load cells and I think I can re-use a bunch of the code, but adding it as a configuration item may be a step too far. I have some of it done, but my free time has been sucked up here lately.

WRT drift - yes, I've got some plans for that.

rkhanso

Well-Known Member

- Joined

- Jan 24, 2017

- Messages

- 785

- Reaction score

- 178

@DaveS and @LBussy -

I use Home Assistant to control a lot of stuff at my house - IoT types of things. I use load cells on my bed to detect when my wife or I are in bed to turn off lights and turn the alarm on when we're both in bed after a certain time at night. It uses that weight info to turn off the alarm off and turn on my office light when I get out of bed in the morning.

The guy who wrote the code for that included an "auto-tare" function to compensate for drift. There's an automation in Home Assistant to do this every day when we're not in bed. I don't know how it works (or if it really works).

The project for this is located HERE and HERE if you want to check it out.

I was thinking about integrating weight sensor data from my kegs in the Kegerator into my Home Assistant dashboard to determine when I was low on beer. Then I found Keg Cop and thought that actually measuring the volume of beer coming out the tap would be much more accurate to determine when it's near time to swap kegs.

I use Home Assistant to control a lot of stuff at my house - IoT types of things. I use load cells on my bed to detect when my wife or I are in bed to turn off lights and turn the alarm on when we're both in bed after a certain time at night. It uses that weight info to turn off the alarm off and turn on my office light when I get out of bed in the morning.

The guy who wrote the code for that included an "auto-tare" function to compensate for drift. There's an automation in Home Assistant to do this every day when we're not in bed. I don't know how it works (or if it really works).

The project for this is located HERE and HERE if you want to check it out.

I was thinking about integrating weight sensor data from my kegs in the Kegerator into my Home Assistant dashboard to determine when I was low on beer. Then I found Keg Cop and thought that actually measuring the volume of beer coming out the tap would be much more accurate to determine when it's near time to swap kegs.

DaveS

Well-Known Member

@rkhanso ,thanks for the links,will check them out.

I use openhab to automate things around my house and monitor my keezer and brewpiless using MQTT.

I had the same idea of using loadcells and an LCD to show bargraphs of how much beer is remaining and MQTT this info to openhab,then found kegcop and this is much better than my limited coding skills would ever accomplish.

There are some wiring tricks I have found to work to reduce drift over time on the HX711 amplifier boards,there are some floating grounds on the green boards that cause erratic readings.

Not sure how an auto tare function could work in his application as the keg weight obviously changes with every pour.

My idea was to reset the bargraph to full when hooking up a keg and when that weight dropped by close to19 kg show it is empty,this way any 19 litre keg can be used, my kegs have different empty weight.

I will watch with interest what Mr Bussy comes up with.

Cheers

I use openhab to automate things around my house and monitor my keezer and brewpiless using MQTT.

I had the same idea of using loadcells and an LCD to show bargraphs of how much beer is remaining and MQTT this info to openhab,then found kegcop and this is much better than my limited coding skills would ever accomplish.

There are some wiring tricks I have found to work to reduce drift over time on the HX711 amplifier boards,there are some floating grounds on the green boards that cause erratic readings.

Not sure how an auto tare function could work in his application as the keg weight obviously changes with every pour.

My idea was to reset the bargraph to full when hooking up a keg and when that weight dropped by close to19 kg show it is empty,this way any 19 litre keg can be used, my kegs have different empty weight.

I will watch with interest what Mr Bussy comes up with.

Cheers

Auto-tare won't work in this application.

What most do is include a reference cell...

Cheers!

What most do is include a reference cell...

Cheers!

The guy who wrote the code for that included an "auto-tare" function to compensate for drift.

Well, yes and no.Auto-tare won't work in this application.

What most do is include a reference cell...

First of all, we must accept the following:

- A (good quality) flowmeter will be more accurate than a load cell measuring a keg getting banged around in a moist climate surrounded by other kegs and lines

- All load cells drift

- We pour beer in increments generally greater than a couple of ounces

- Keg Cop and RPints before it discard "small pours" that can happen due to bubbles (generally micro-ounces)

- Anything less than a couple of ounces (probably by an order of magnitude) is probably drift

rkhanso

Well-Known Member

- Joined

- Jan 24, 2017

- Messages

- 785

- Reaction score

- 178

Yeah, I guess auto-tare will just reset the new weight to zero. Not what you want it to do.

If I'm understanding this correctly now.

If I'm understanding this correctly now.

I mean "auto tare but remember the last volume" sort of works.

Really?

rkhanso

Well-Known Member

- Joined

- Jan 24, 2017

- Messages

- 785

- Reaction score

- 178

I'm banking on the flow meter.

Gotta be a lot better.

Will be ordering the PCBs soon, I hope.

Gotta be a lot better.

Will be ordering the PCBs soon, I hope.

DaveS

Well-Known Member

Would anyone presently using flow meters comment on foaming and the cleaning procedure required.

I assumed flow meters would be a pita to clean and don't want foaming issues,that is why was looking at a load cell option.

Perhaps they are not too bad after all.

Cheers

I assumed flow meters would be a pita to clean and don't want foaming issues,that is why was looking at a load cell option.

Perhaps they are not too bad after all.

Cheers

Assuming I understand the question: If you keep the lines horizontal or slightly downward-sloping through the flowmeters, you do not get "interference" from bubbles. If you mean causing foaming, no, not with the SwissFlow anyway. There are some which use a turbine sort of setup which may not be as gentle but I do not have extended experience with the cheaper ones.

As far as cleaning goes, I just do like normal, BLC and/or Saniclean (I stopped using Star-San but that works too.)

As far as cleaning goes, I just do like normal, BLC and/or Saniclean (I stopped using Star-San but that works too.)

I've been running six sf800s since 2014 with literally zero dispensing issues over that time. For cleaning I rinse the lines from QDs through faucets, then recirculate warm-ish BLC or LLC, whichever I have on hand, through all six lines in parallel for 20 minutes, then do a long non-circulating rinse, then blow out the lines and hook them all back up. No biggie...

Cheers!

Cheers!

theglobalguy

Active Member

Just ordered all the parts for this; thanks for making the Mouser links to the projects...saved a ton of time. Looking forward to getting this going. I'd been using the flowmeters connected directly to Raspberry Pints, but this seems like a more elegant solution long term.

Certainly allowing people to integrate this into RPints was a goal so I'd be interested to hear how it works out for you. I would not be surprised if some tweaks are warranted.I'd been using the flowmeters connected directly to Raspberry Pints, but this seems like a more elegant solution long term.

I may also be your huckleberry. Just ordered all the parts from China a couple days ago.Certainly allowing people to integrate this into RPints was a goal so I'd be interested to hear how it works out for you. I would not be surprised if some tweaks are warranted.

Something which may help folks who are working out their plumbing:

https://www.ebay.com/itm/Kegland-Ba...nnector-Gas-Liquid-Pushfit-Pair-/334197024544

It’s still in Europe, but this may be the thing you need, or at least we know it’s coming soon.

https://www.ebay.com/itm/Kegland-Ba...nnector-Gas-Liquid-Pushfit-Pair-/334197024544

It’s still in Europe, but this may be the thing you need, or at least we know it’s coming soon.

Similar threads

- Replies

- 271

- Views

- 16K