You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

iSpindle - DIY Electronic Hydrometer

- Thread starter LBussy

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

BreeBrew

Well-Known Member

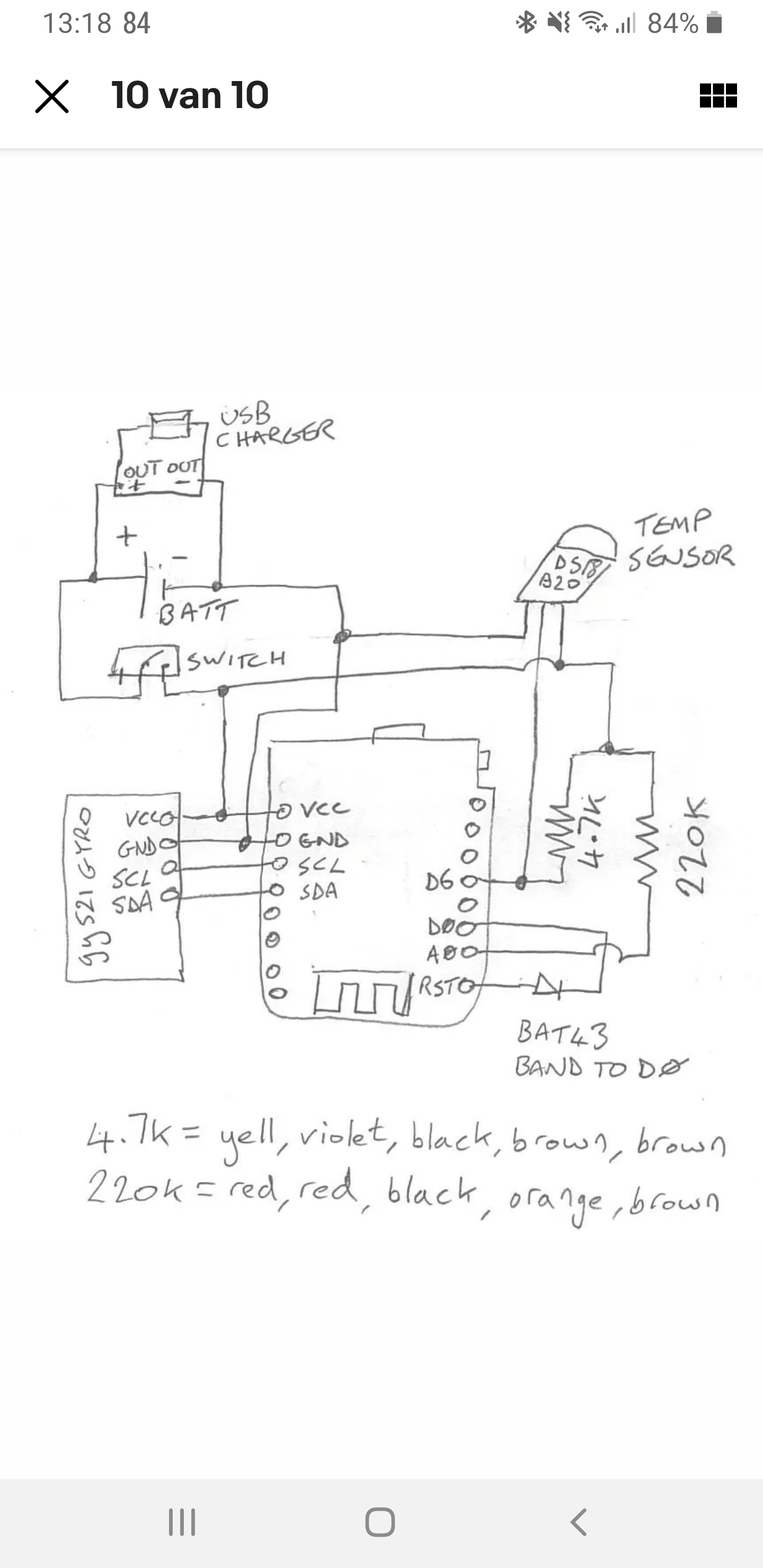

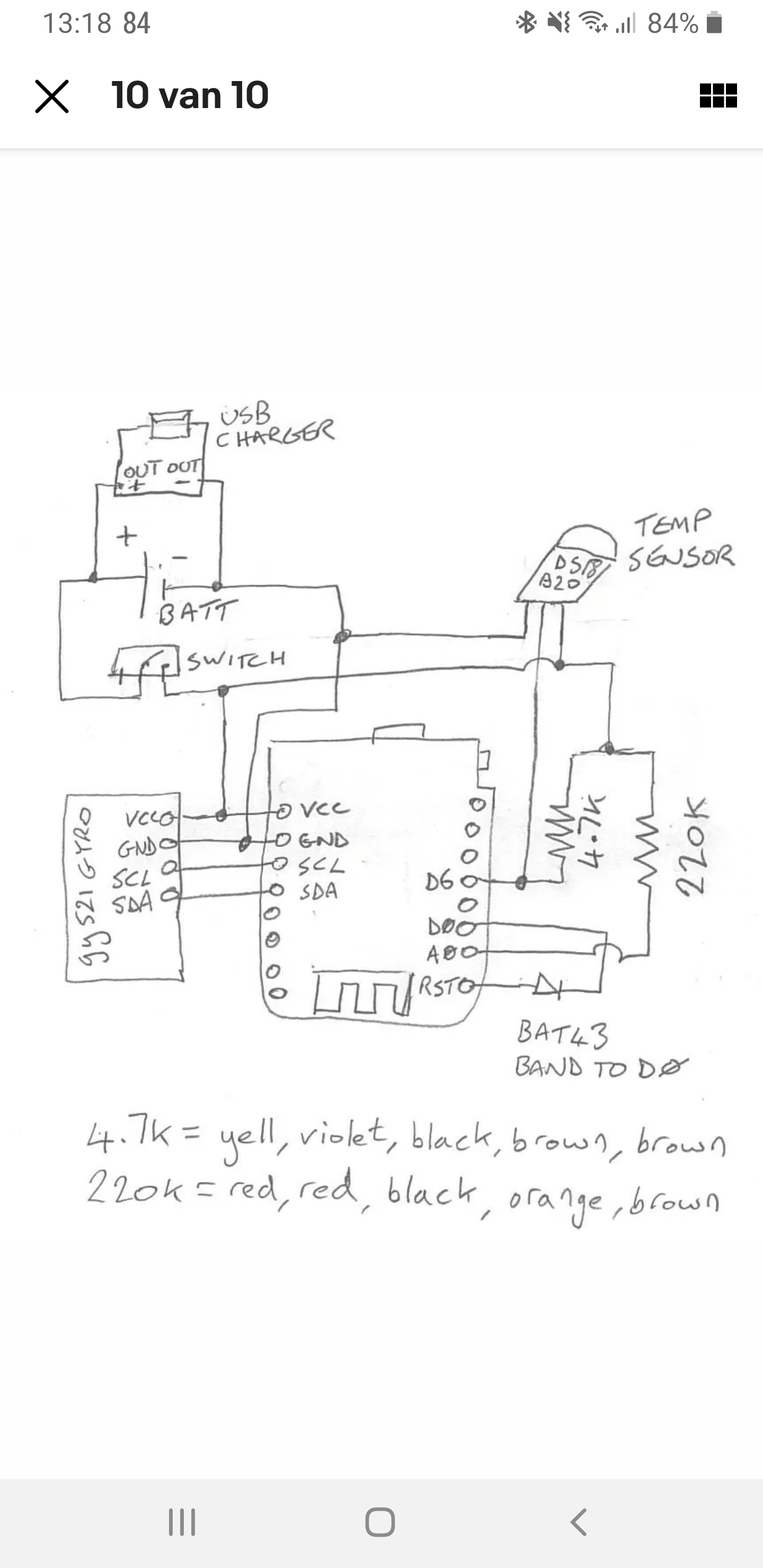

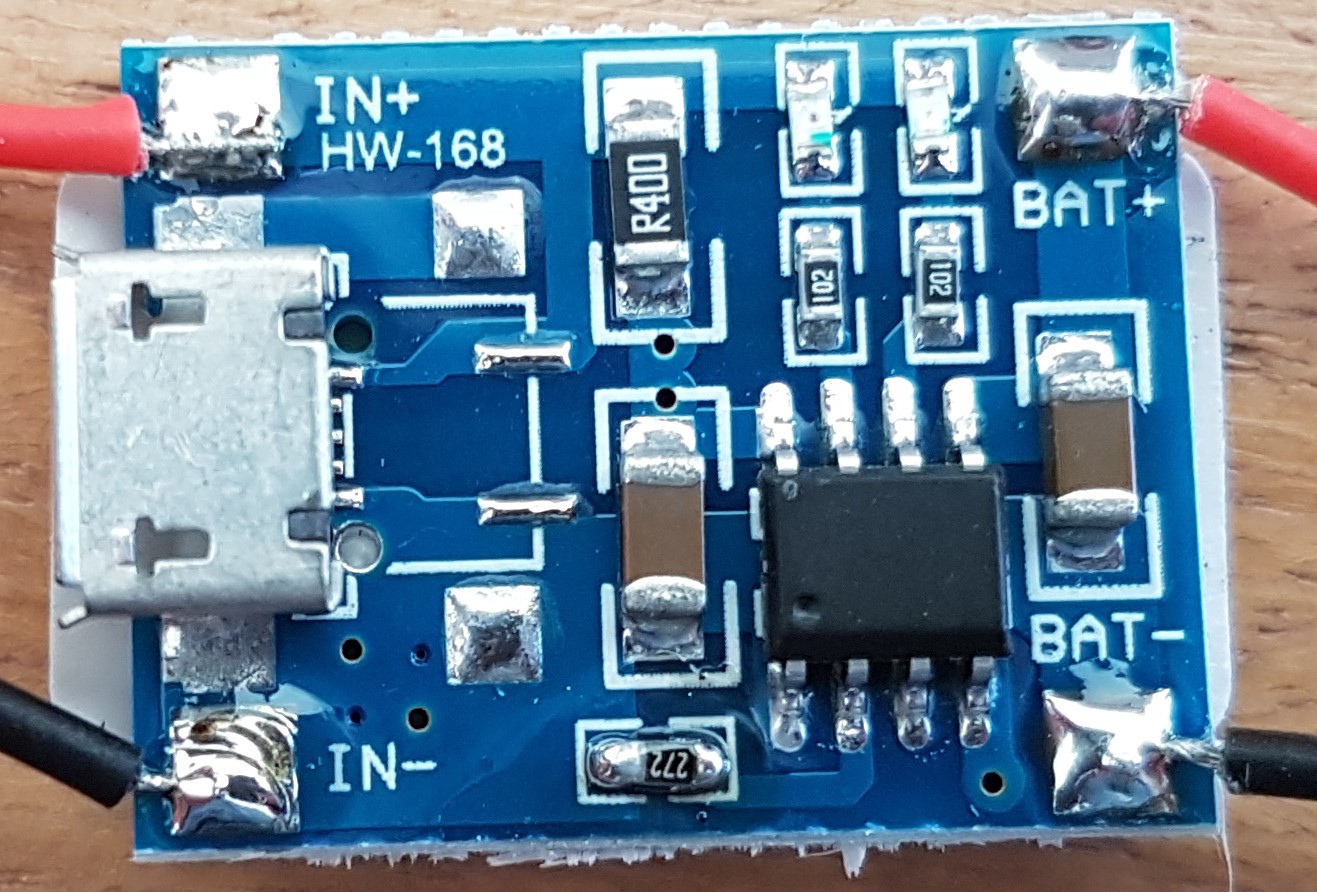

Well I guess you'll have to stick with diagram that is on the eBay link that you provider namely:

And also read this: https://www.hotmcu.com/tp4056-micro-usb-5v-1a-lithium-battery-charger-module-p-145.html

And ask the seller!

And also read this: https://www.hotmcu.com/tp4056-micro-usb-5v-1a-lithium-battery-charger-module-p-145.html

And ask the seller!

iSpindel up and running!! Big Thanks to @jbeavis19 for the kit.

Last edited:

Setup an iSPindel last night, but had a lot of trouble flashing. Plugged it into windows and it assigned a device name (CH340) and port number (7), I open Nodemcu and it said "Waiting MAC" and nothing was happening. I cycled the power a several times quickly and itfinally populated the MAC information. It then was able to be flashed (though very slowly). I was then able to see an iSpindel on Wifi and connect. I opened configuration and everything looked good, Temp, Voltage, and angle all functioned and look accurate. So I put it on charger and went to be.... Then this morning...oof.

I log into the iSPindel and it wants to crash, webpage say it cannot connect, and the iSpindel wifi network disappears. Log back in, I goto change C to F, and it wont save, SO i go to followed the instructions to clear the flash and try again, but I cant get it to flash. I got it to populate the MAC address a few times, yet even then it wont flash. Can someone clue me in on possible issue or solutions. Thanks.

I log into the iSPindel and it wants to crash, webpage say it cannot connect, and the iSpindel wifi network disappears. Log back in, I goto change C to F, and it wont save, SO i go to followed the instructions to clear the flash and try again, but I cant get it to flash. I got it to populate the MAC address a few times, yet even then it wont flash. Can someone clue me in on possible issue or solutions. Thanks.

OK, so I retouched all the solder joints. Seems to have fixed everything. I have it flashed and its saving everything. It calibrates at 89 degrees, and in water is 16.4 degrees. Ive read it needs to be 25 degrees in water, but I think i was before we had the option to fast calibrate on a level table. Can any speak to this? SO you know, Im not actually looking for a perfect reading, just wanna be close enough to watch attenuation. DO i need to go further in calibration than just the level table for my needs?

Last edited:

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

Open Source Distilling

OpenSourceDistilling.com

- Joined

- Nov 14, 2019

- Messages

- 20

- Reaction score

- 25

OK, so I retouched all the solder joints. Seems to have fixed everything. I have it flashed and its saving everything. It calibrates at 89 degrees, and in water is 16.4 degrees. Ive read it needs to be 25 degrees in water, but I think i was before we had the option to fast calibrate on a level table. Can any speak to this? SO you know, Im not actually looking for a perfect reading, just wanna be close enough to watch attenuation. DO i need to go further in calibration than just the level table for my needs?

What board are you using? The PCB 4.0? The Jeffrey? Or something else?

The general consensus is that you must get to 20 to 30 degrees in pure water, preferably 25 degrees... after offset calibration. The Jeffrey has a movable battery to fine-tune the tilt in pure water (it also has places to afix weights). If you are using PCB 4.0 you can try adding weights or put some styrofoam (or something) in the bottom of the petling to push the assembly toward the lid to get a higher tilt.

I'm not experienced in the consequences of not getting to the 20 to 30 degree range. I've only read that it's required on the official iSpindel Github. Apparently this has effects on the accuracy of the iSpindel during real-life fermentation.

Please, if I got something wrong or someone has something to add, comment and let me/us know.

Open Source Distilling

OpenSourceDistilling.com

- Joined

- Nov 14, 2019

- Messages

- 20

- Reaction score

- 25

OK, so I retouched all the solder joints. Seems to have fixed everything. I have it flashed and its saving everything. It calibrates at 89 degrees, and in water is 16.4 degrees. Ive read it needs to be 25 degrees in water, but I think i was before we had the option to fast calibrate on a level table. Can any speak to this? SO you know, Im not actually looking for a perfect reading, just wanna be close enough to watch attenuation. DO i need to go further in calibration than just the level table for my needs?

Here is a link to the iSpindel FAQ page. The first entry talks about 25 degrees in water.

http://www.ispindel.de/docs/FAQ-en.html

Thanks @Open Source Distilling ill check it out. It's the 4.0 PCB. I'll check the link, but I notice your video offset calibrated with the lip at the top of the tube touching the flat surface, while I've also run folks calibrating with the tube flat to the table. What practice is better? I can balance with lead weight very accurately now (after screwing with it for a few hours)

Anyway, I'm back to square one for the moment. Everything worked going to bed, when I woke up and it was offline. Had it set to an update every 20 seconds, but it wasn't flashing anymore, battery was 4.01V. Rebooted and the blue light wasn't flashing as it was before. Don't know if it's running and not flashing, or just dead and not running. I guess some sort of serial port monitoring would be necessary. First D1 I've used so 1 haven't a clue how that is done yet.

Anyway, I'm back to square one for the moment. Everything worked going to bed, when I woke up and it was offline. Had it set to an update every 20 seconds, but it wasn't flashing anymore, battery was 4.01V. Rebooted and the blue light wasn't flashing as it was before. Don't know if it's running and not flashing, or just dead and not running. I guess some sort of serial port monitoring would be necessary. First D1 I've used so 1 haven't a clue how that is done yet.

Open Source Distilling

OpenSourceDistilling.com

- Joined

- Nov 14, 2019

- Messages

- 20

- Reaction score

- 25

Thanks @Open Source Distilling ill check it out. It's the 4.0 PCB. I'll check the link, but I notice your video offset calibrated with the lip at the top of the tube touching the flat surface, while I've also run folks calibrating with the tube flat to the table. What practice is better? I can balance with lead weight very accurately now (after screwing with it for a few hours)

Anyway, I'm back to square one for the moment. Everything worked going to bed, when I woke up and it was offline. Had it set to an update every 20 seconds, but it wasn't flashing anymore, battery was 4.01V. Rebooted and the blue light wasn't flashing as it was before. Don't know if it's running and not flashing, or just dead and not running. I guess some sort of serial port monitoring would be necessary. First D1 I've used so 1 haven't a clue how that is done yet.

I never thought about calibrating and the lip on one side of the petling. I don't know what's better... I suppose that it would be 'flatter' with just the tube portion touching. I'll need to think more about this.

Are you able to post a pic or email me a pic ([email protected]) of the weights you added? I have a few 4.0 PCB iSpindel that I'll be including in an upcoming video about 25-degree calibration. I just can't seem to get them to float right.

Sure, I'll take a photo tonight, and maybe weight it. It isn't pretty but I was able to get 25.5 degrees easy enough. I used a lead screw anchor (see pic) , smashed it flat, then bent it to fit like a half moon inside the very top of the tube just above the USB C port. I then cut it in half, stacked it, and wrapped it in blue painters tape. I can gently snug it into place between the USB c port and the outside wall, and it stays flush to the top of the tube. The best option would probably be car wheel weights, the flat kind with adhesive tape. But covid rendered visiting a tire shop locally impossible. Amazon has them for $18 for a bunch, but that's a lot. I'll get you a pic of my iSpindel tonight when I get home.

Attachments

I'll share this. My iSpindel in tap water rested at 16 degrees. I taped a quarter to the outside lid and hit 18.5. If that quarter where lead, you'd be very close, but who wants lead in your beer. So the solution is to 3d print in petg, but my printer doesn't get hot enough for that. Otherwise it'd be easy to print a new cap with some headroom. AND the Jeffrey pcb looks like it solves this? also might be possible to find a silicone gasket for the cap to seat against rather than the tube, thus proving the additional clearance inside the cap. Cuz there just not enough room inside that freaking tube. Did I say I wanted a Jeffrey board

My original solution was to use old school lead solder, but I couldn't find it when I needed it. Maybe you have that around.

My original solution was to use old school lead solder, but I couldn't find it when I needed it. Maybe you have that around.

Last edited:

Few pics of lead weights in painter tape. Ugly but...till I can get proper wheel weights it'll do. This weighs .35 oz / 10g.

Attachments

Last edited:

Open Source Distilling

OpenSourceDistilling.com

- Joined

- Nov 14, 2019

- Messages

- 20

- Reaction score

- 25

Few pics of lead weights in painter tape. Ugly but...till I can get proper wheel weights it'll do.

Got it! Thanks! My 4.0 PCBs also float at about 16 degrees in water.

I see that your weight is 'floating' inside the petling. I never thought of that as an option. Good job. If it works it works, no need to be fancy about it.

The problem I kept having was that there wasn't a good place to afix weights to the 4.0 PCB. I tried lead tape on the lid and then thought better of it. I don't want lead in direct contact with something that is in direct contact with booze I'll be drinking. I tried adding weights further away from the lid but that resulted in having to add so much weight that the iSpindel could no longer float and sank. I then decided to build my own board.

Yes, The Jeffrey solves 25 degrees in water problem. In my builds that I've tested, The Jeffrey floated at 25 degrees in water when the battery is placed in the lowest position. Moving the battery up will increase the tilt in water. I also included a perforated area at the bottom where a couple of nuts can be glued, double-sided taped, sewn with thread and needle... or attached by whatever means necessary. The weights are used to decrease the tilt in water. Between those two mechanisms (moveable battery, place to add weights) we should be able to get to 25 degrees regardless of how much your battery weights or what supplier you bought your components from. The exact weight of the components we buy is outside of our control so we need some kind of mechanism to adjust for that.

I tracked down my intermittent issue, I have a bad trace on the wemos. The RST pin and D0 are connected via the Bat 43 diode, it's part of the wake up system. Currently it runs, flashes, and sends data....but it won't come out of sleep. I need to know where the RST and D0 pins actually connect to the chip in the wemos, then place the bat 43 between them. That will fix my problem. I haven't dug a lot yet but maybe some here knows. Not an impossible question, but it's a double sided board and if it routes to the bottom side....ooof....I'll.be buying a new one lol.

DaniFilth

Well-Known Member

- Joined

- Feb 6, 2019

- Messages

- 72

- Reaction score

- 3

Hi all. I finally finished taking down all the numbers for my ispindle while it fermented in sugar water.

Ended up with around 33 readings, took both tilt and angle alongside my hydrometer.

After using the online calculator i got

Degree 1:y = 0.002424467x + 0.9116992

Degree 2:y = 0.000059975x^2 + -0.00388996x + 1.06777266

Degree 3:y = 0.000001739x^3 + -0.000204593x^2 + 0.009064298x + 0.864194726

Is it the last line i input into the ispindle gravity conversion or the second?

Ended up with around 33 readings, took both tilt and angle alongside my hydrometer.

After using the online calculator i got

Degree 1:y = 0.002424467x + 0.9116992

Degree 2:y = 0.000059975x^2 + -0.00388996x + 1.06777266

Degree 3:y = 0.000001739x^3 + -0.000204593x^2 + 0.009064298x + 0.864194726

Is it the last line i input into the ispindle gravity conversion or the second?

Hello everyone! I assembled iSpindel, but there was a problem. When turned on, the battery charge is defined as 0.11-0.09 volts, although the battery actually has 3.9 volts. Sr2100 diode, 4.7k, 220k resistors. What is the problem?

Hello everyone! I assembled iSpindel, but there was a problem. When turned on, the battery charge is defined as 0.11-0.09 volts, although the battery actually has 3.9 volts. Sr2100 diode, 4.7k, 220k resistors. What is the problem?

Make sure one side of the 220k resistor is connected to 5V and the other to A0 on the Wemos.

brownbucks11

New Member

- Joined

- Dec 16, 2016

- Messages

- 1

- Reaction score

- 0

Got it! Thanks! My 4.0 PCBs also float at about 16 degrees in water.

I see that your weight is 'floating' inside the petling. I never thought of that as an option. Good job. If it works it works, no need to be fancy about it.

The problem I kept having was that there wasn't a good place to afix weights to the 4.0 PCB. I tried lead tape on the lid and then thought better of it. I don't want lead in direct contact with something that is in direct contact with booze I'll be drinking. I tried adding weights further away from the lid but that resulted in having to add so much weight that the iSpindel could no longer float and sank. I then decided to build my own board.

Yes, The Jeffrey solves 25 degrees in water problem. In my builds that I've tested, The Jeffrey floated at 25 degrees in water when the battery is placed in the lowest position. Moving the battery up will increase the tilt in water. I also included a perforated area at the bottom where a couple of nuts can be glued, double-sided taped, sewn with thread and needle... or attached by whatever means necessary. The weights are used to decrease the tilt in water. Between those two mechanisms (moveable battery, place to add weights) we should be able to get to 25 degrees regardless of how much your battery weights or what supplier you bought your components from. The exact weight of the components we buy is outside of our control so we need some kind of mechanism to adjust for that.

What technique do you use to move the battery holder up on the Jeffrey 2.0 after it has been soldered in place?

Me again - finished my iSpindel a few days ago but didn't get around to calibrating it till this weekend.

The issue i seem to have is the the iSpindel sends one reading once turned on but then doesn't send any more after that.

I'm using Fermentrack to capture the data and it seems to connect OK but like i said - only seems to send one reading.

I turned the update frequency to 30 secs to try and test but it didn't seem to help.

Anyone got any advice?!

The issue i seem to have is the the iSpindel sends one reading once turned on but then doesn't send any more after that.

I'm using Fermentrack to capture the data and it seems to connect OK but like i said - only seems to send one reading.

I turned the update frequency to 30 secs to try and test but it didn't seem to help.

Anyone got any advice?!

Open Source Distilling

OpenSourceDistilling.com

- Joined

- Nov 14, 2019

- Messages

- 20

- Reaction score

- 25

Few pics of lead weights in painter tape. Ugly but...till I can get proper wheel weights it'll do. This weighs .35 oz / 10g.

Hey @Wild7s Can I use the pics of the weights you added to your PCB 4.0 in an upcoming video? I'm making a video about balancing iSpindels to 25 degrees in pure water. I used a different method than you for the PCB 4.0 but would like to reference your method as well. I'll give you shout out/credits during the video. Let me know!

Joey Joe Joe Jr.

Sounds like it's not waking up from sleep. Check the connection between D0 and RST. Are you using a diode there? Negative side (with the white bar) should be connected to D0.The issue i seem to have is the the iSpindel sends one reading once turned on but then doesn't send any more after that.

DJ_L3ThAL

Member

- Joined

- Oct 27, 2017

- Messages

- 11

- Reaction score

- 4

Hi guys,

Having issues with my second ispindel, same wifi as the first working one. Have zero'd and reflashed firmware and reset factory settings. I looked in the log and am getting a message that Internet Explorer is not supported by Brewfather, Please upgrade to a new browser. Also another message below that saying please enable JavaScript to continue using this application??? So strange as the first ispindel is logging perfectly and in a brew as we speak via the same network. Any ideas how to rectify this?

One setting I was not sure about with Brewfather loggin was the token setting? I cannot find anywhere how to find this and wonder if it is set by the application when you first connect automatically?

Having issues with my second ispindel, same wifi as the first working one. Have zero'd and reflashed firmware and reset factory settings. I looked in the log and am getting a message that Internet Explorer is not supported by Brewfather, Please upgrade to a new browser. Also another message below that saying please enable JavaScript to continue using this application??? So strange as the first ispindel is logging perfectly and in a brew as we speak via the same network. Any ideas how to rectify this?

One setting I was not sure about with Brewfather loggin was the token setting? I cannot find anywhere how to find this and wonder if it is set by the application when you first connect automatically?

DJ_L3ThAL

Member

- Joined

- Oct 27, 2017

- Messages

- 11

- Reaction score

- 4

Silly me, I forgot to include the "BLANK" line in the ESP8266 Flasher when wiping the unit. I did that again, re-flashed new firmware (6.2.0) and it now reads into Brewfather. The problem is the original issue I was trying to resolve with a wipe/re-flash is present. The unit reports into Brewfather for a number of hours but then appears to stop. I had the logger running overnight but my PC either decided to reboot or it crashed and rebooted so I lost the log from PuTTY.

Everything looks normal to me when it boots up now, the router is right next to it and a 2.4GHz only channel. The one thing that stands out is the reported battery voltage (The power switch is off and the unit is plugged into a USB 3.0 port on my PC) is 4.7V, that seems low for USB 5.0V power or do they self regulate on the input from a PC and that is not an issue? I have pasted the latest log below, whilst the status is ignored, that report is viewable in Brewfather no worries!

FW 6.2.0

2.2.1(cfd48f3)

Worker run!

mounting FS... mounted!

reading config file

parsed config:

{"Name":"ispindel2","Token":"","Sleep":900,"Server":"log.brewfather.net","API":3,"Port":80,"Channel":0,"URI":"/ispindel?id=BLANKEDINTENTIONALLY","DB":"ispindel","Username":"","Password":"","Job":"ispindel","Instance":"000","Vfact":191.8,"TS":0,"OWpin":12,"POLY":"-0.00468523*tilt^2+0.936003295*tilt-20.207624944","SSID":"BLANKEDINTENTIONALLY","PSK":"BLANKEDINTENTIONALLY","Offset":[0,0,0,0,0,0]}

offsets not available

Boot-Mode: Deep-Sleep Wake

woken from deepsleep, normal mode

Samples:42 min:65.22 max:65.35 time:757

x: -9618 y: 13936 z: 488

Tilt: 65.28

Tacc: 22.86

Volt: 4.77

Temp: 20.56

Gravity: 20.93

IP: BLANKEDINTENTIONALLY

calling HTTP

{"name":"Yellow_Green","ID":287783,"angle":65.27937,"temperature":20.5625,"temp_units":"C","battery":4.770594,"gravity":20.92846,"interval":900,"RSSI":-42}HTTPAPI: posting

code: 200

{ "result": "ignored" }

Final-sleep: 900s; RT: 2456

Everything looks normal to me when it boots up now, the router is right next to it and a 2.4GHz only channel. The one thing that stands out is the reported battery voltage (The power switch is off and the unit is plugged into a USB 3.0 port on my PC) is 4.7V, that seems low for USB 5.0V power or do they self regulate on the input from a PC and that is not an issue? I have pasted the latest log below, whilst the status is ignored, that report is viewable in Brewfather no worries!

FW 6.2.0

2.2.1(cfd48f3)

Worker run!

mounting FS... mounted!

reading config file

parsed config:

{"Name":"ispindel2","Token":"","Sleep":900,"Server":"log.brewfather.net","API":3,"Port":80,"Channel":0,"URI":"/ispindel?id=BLANKEDINTENTIONALLY","DB":"ispindel","Username":"","Password":"","Job":"ispindel","Instance":"000","Vfact":191.8,"TS":0,"OWpin":12,"POLY":"-0.00468523*tilt^2+0.936003295*tilt-20.207624944","SSID":"BLANKEDINTENTIONALLY","PSK":"BLANKEDINTENTIONALLY","Offset":[0,0,0,0,0,0]}

offsets not available

Boot-Mode: Deep-Sleep Wake

woken from deepsleep, normal mode

Samples:42 min:65.22 max:65.35 time:757

x: -9618 y: 13936 z: 488

Tilt: 65.28

Tacc: 22.86

Volt: 4.77

Temp: 20.56

Gravity: 20.93

IP: BLANKEDINTENTIONALLY

calling HTTP

{"name":"Yellow_Green","ID":287783,"angle":65.27937,"temperature":20.5625,"temp_units":"C","battery":4.770594,"gravity":20.92846,"interval":900,"RSSI":-42}HTTPAPI: posting

code: 200

{ "result": "ignored" }

Final-sleep: 900s; RT: 2456

Does anyone happen to have a single PCB they'd be willing to sell me? I don't need 5/10 from PCBWay. Something fritzed out with my D1, and in the process of trying to desolder the D1 to remove it and put a new one on, I managed to burn through the soldering cup and expose some of the internal wire. Woops!

I have a couple of my version. With the 3D printed sled if you are interested. PM me, if you are.

Two questions for folks:

1.) Is removing the PCB after calibration a problem? I'm calibrating using Fermentrack, set for 60s intervals. Once i get the polynomial equation, I have to pull the PCB out to enable config mode, to switch the internal to 15 minutes, and data collection source as BrewFather. I'll do my best to put the PCB back in the same spot as it was when it was calibrated, but it won't be exact.

2.) How are people dealing with getting data out of SS fermenters in fridges? Router is in living room upstairs, fermenter is in garage. I set up a Dlink repeater, but when I place the repeater in the fridge and close the door, I can't connect to internet when connected to the extender network on my phone standing outside my fridge. So I'm assuming it's not going to get the job done here.

My Pi running Fermentrack, sitting on top on the fridge, connects to main WFi just fine, but can't read the iSpindel in the fridge. Thus, using the extender to push the data.

1.) Is removing the PCB after calibration a problem? I'm calibrating using Fermentrack, set for 60s intervals. Once i get the polynomial equation, I have to pull the PCB out to enable config mode, to switch the internal to 15 minutes, and data collection source as BrewFather. I'll do my best to put the PCB back in the same spot as it was when it was calibrated, but it won't be exact.

2.) How are people dealing with getting data out of SS fermenters in fridges? Router is in living room upstairs, fermenter is in garage. I set up a Dlink repeater, but when I place the repeater in the fridge and close the door, I can't connect to internet when connected to the extender network on my phone standing outside my fridge. So I'm assuming it's not going to get the job done here.

My Pi running Fermentrack, sitting on top on the fridge, connects to main WFi just fine, but can't read the iSpindel in the fridge. Thus, using the extender to push the data.

Two questions for folks:

1.) Is removing the PCB after calibration a problem? I'm calibrating using Fermentrack, set for 60s intervals. Once i get the polynomial equation, I have to pull the PCB out to enable config mode, to switch the internal to 15 minutes, and data collection source as BrewFather. I'll do my best to put the PCB back in the same spot as it was when it was calibrated, but it won't be exact.

If I'm not mistaken, there is a way to calibrate in fermentrack based on getting the values of the device in plain water and in the O.G. wort. Using those 2 numbers to calibrate, this doesn't require opening the device. This is the method I use in Ubidots because I always shift the angle it sits when I charge the device.

But maybe @Thorrak can clarify, since I haven't used my iSpindel with Fermentrack yet.

I can't help you with #2 because I don't use a stainless fermenter.

If I'm not mistaken, there is a way to calibrate in fermentrack based on getting the values of the device in plain water and in the O.G. wort. Using those 2 numbers to calibrate, this doesn't require opening the device. This is the method I use in Ubidots because I always shift the angle it sits when I charge the device.

But maybe @Thorrak can clarify, since I haven't used my iSpindel with Fermentrack yet.

I can't help you with #2 because I don't use a stainless fermenter.

There's definitely a way to calibrate in Fermentrack.

Admittedly, I've not spent nearly enough time with my iSpindel to really learn the ins-and-outs, but what is this "config" mode you're speaking of @kdw2pd that requires physically accessing the PCB?

Similar threads

- Replies

- 33

- Views

- 8K

- Replies

- 3

- Views

- 1K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)