First off, I don't keg. I only bottle, by choice. No plans to change that anytime real soon. But what's the deal with those chincy plastic spigots and bottling wands??? In almost every other area of homebrewing there are high quality options for those willing to spend a little more money. Why not for bottling?

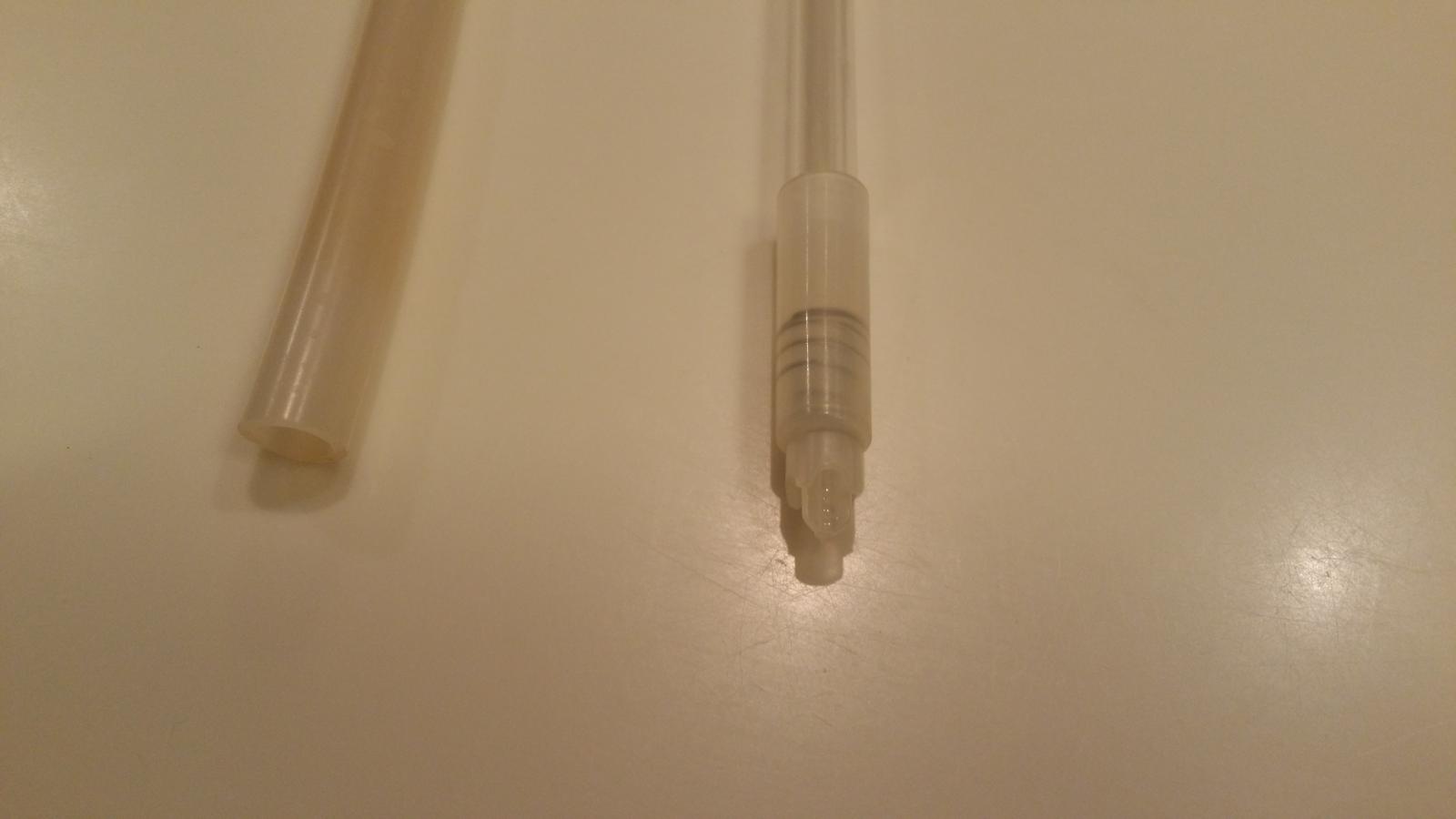

The problem is, I get a small air bubble at the beginning of every single bottle that I fill. It's either coming in through the spigot, the bottling wand, or the hose connecting the two. Everything looks snug, there are no leaks, and after that initial bubble the fill seems to be bubble-free. I don't mind replacing all these pieces, but why can't I do so with something of a higher quality? I've searched a ton of equipment sellers, and they all sell what appear to be the same thing. If anyone out there can point me to some that are of a higher quality, please do so and I will be greatly appreciative.

The problem is, I get a small air bubble at the beginning of every single bottle that I fill. It's either coming in through the spigot, the bottling wand, or the hose connecting the two. Everything looks snug, there are no leaks, and after that initial bubble the fill seems to be bubble-free. I don't mind replacing all these pieces, but why can't I do so with something of a higher quality? I've searched a ton of equipment sellers, and they all sell what appear to be the same thing. If anyone out there can point me to some that are of a higher quality, please do so and I will be greatly appreciative.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)