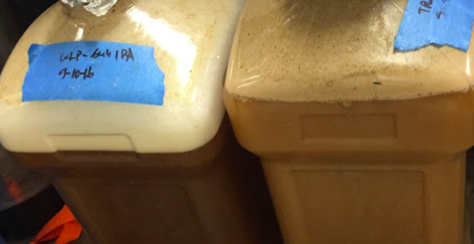

One very simple indicator that you've kept the oxygen level low is the color of the wort. Here is a picture of wort from side-by-side helles mashes taken by Brody over at the GBF on

this thread. One is a normal mash and the other is LODO:

Brody was not one of the authors of the paper, but he was one of the earliest adopters who gave it a try, so I'd like to think that he's pretty unbiased.

If you do two side-by-side mashes, or even mini-mashes, and you see this kind of color difference, then you can pretty safely assume that you protected the wort from oxygen even without using a DO meter. The difference in taste of the worts at this point in time is pretty huge too.

Of course, like you say it's very easy to screw up the process down the line and lose a lot of flavor. But if you can prove to yourself that a very real difference exists at the mash/boil stage, I think it takes some mental gymnastics to conclude that such a difference cannot possibly be carried over into the final product.

At that point, I think that most reasonable people who found a huge difference in the wort but little difference in their finished beer would be asking "Where did I drop the ball?" rather than "LODO is a fraud!"

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)