Wanted to show you fine folks my keg purging procedure for ball lock corny kegs. I think it's a pretty darn good way to get air out of them. Let me know if y'all have any ideas for improvements.

Oh and many thanks to others here who put into my head this whole idea of purging with sanitizer and CO2. My idea is simply a permutation of what other folks are, and have been, doing.

First, the key to how I purge is one of these nifty keg rinsers from MoreBeer. You can probably make one yourself for cheaper, but I went the easy route.

https://www.morebeer.com/products/morebeer-ball-lock-keg-rinser.html

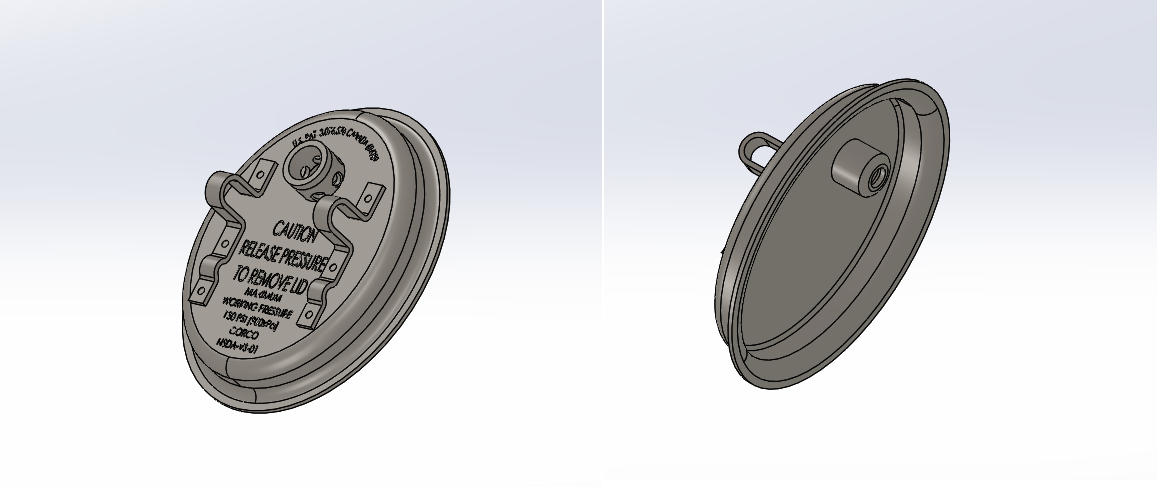

I should also note that you need to trim/shorten the gas dip tube in order for this to work. Mine are now so short that you can't feel them protruding into the inside of the keg.

I put Star San in the keg and connect the liquid out to the water hose (using the keg rinser gizmo) so that it fills from the bottom and minimizes foaming. While filling I allow the keg lid to dangle loosely inside the keg from the keg's opening.

As soon as the sanitizer has started to overflow the keg I pull the lid into position and the pressure from the water hose seals up the keg. I push the sealing mechanism down on the keg lid as well.

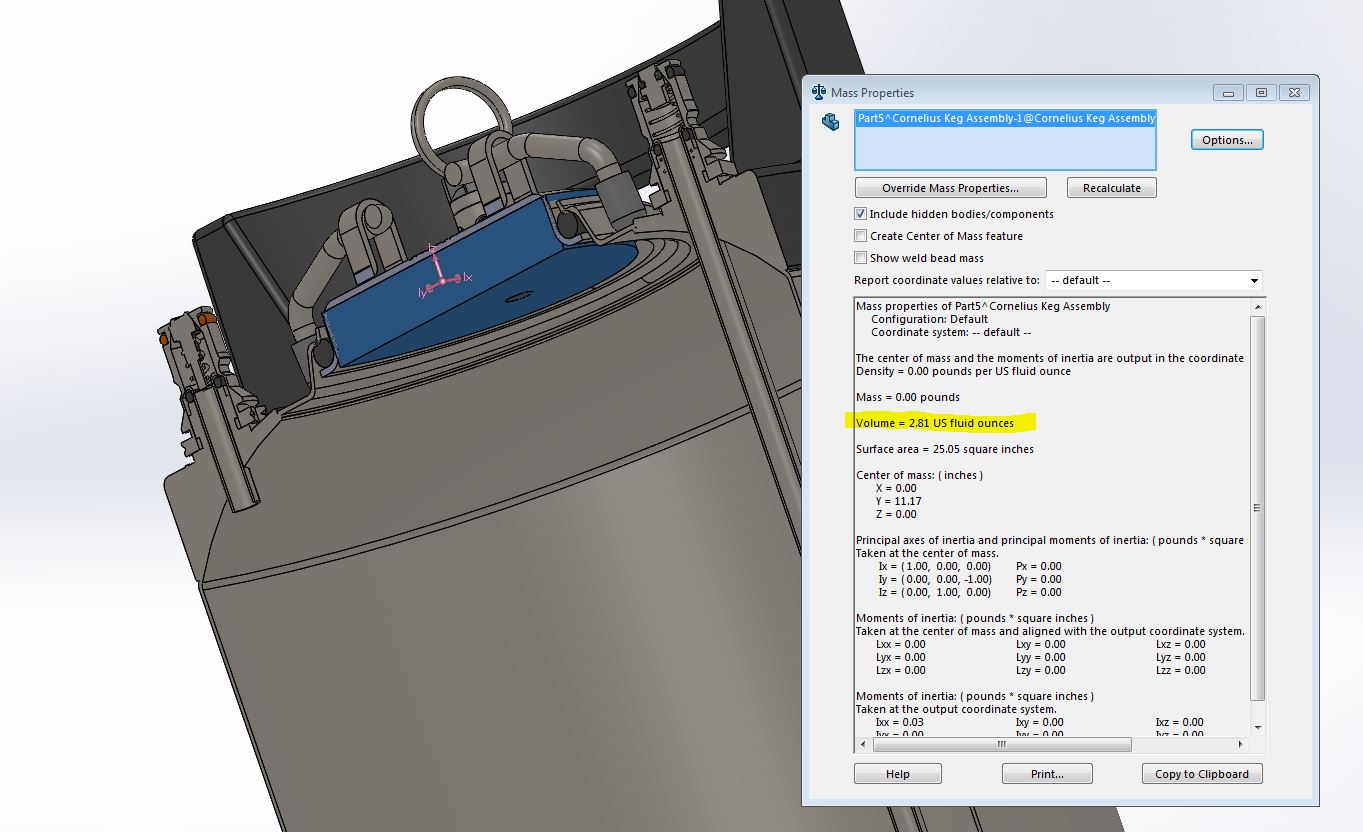

Leaving the water hose connected, I then gently crack the PSV in the lid to push out any trapped air that might have collected there. Next, I lean the keg over so that the gas post is as close to the high point of the keg as possible. I shake the keg several times so that any air pockets trapped in other nooks and crannies will make their way to this high point. If I'm feeling froggy, I'll even turn it upside down, then back right side up, shaking some more. Then I depress the poppet in the gas post until there's only liquid coming out. A little air always comes out first.

The water from the hose will push any air pockets out the PSV and gas post. I believe this eliminates almost all the air, and more importantly oxygen, from the keg, which is what we're after.

Then I disconnect the water hose from the keg. At this point I simply use CO2 to push the sanitizer out the liquid line. Make sure to relieve the pressure on the keg before connecting the CO2. You don't want water back flowing into your gas line.

Let me know your thoughts or ideas. Am I full of hog wash thinking this actually gets most, if not all, air out? I've been told that due to the geometry of the corny keg it would be impossible.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)