SpikeBrewing

Well-Known Member

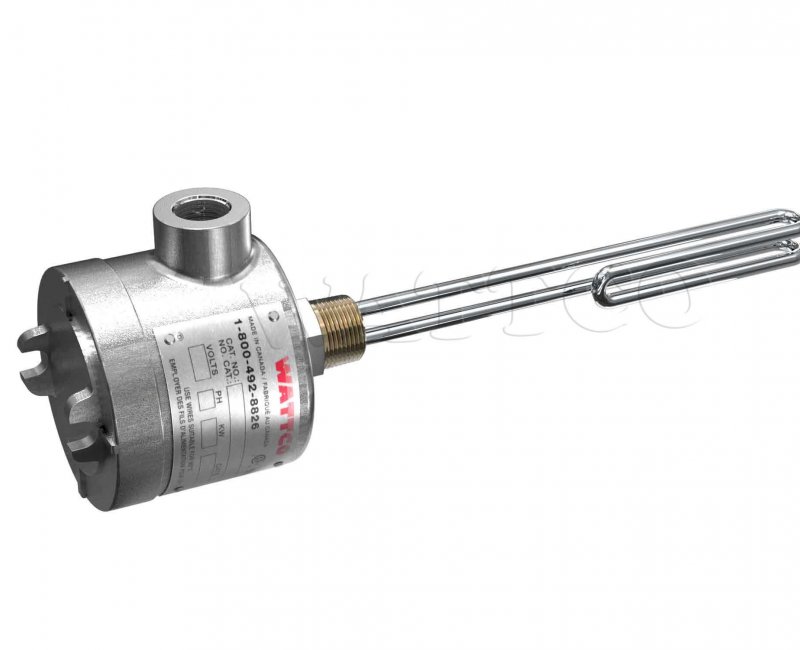

The 1" couplers just got in today. They need to machined to the straight thread. The machinist is finishing up the tooling for the welding. I'll get on him and hopefully it'll be done by the weekend.

Will you offer just the coupler as well for those of us that want to add it to our kettle?

Update?

I think I'm going to want a 20gallon one when you get it all set up. I'm going to need an extra two 1/2 coupler for the the HEX. What do you charge per extra coupling?

The closer it is to plug and play the more interested I am. Electricity is an area where I get nervous with diy

THIS. I would also be interested in as plug-n-play a system as y'all could create. Although I'm guessing I brew on a smaller scale (still on 5 gallon batches) than most.

BTW: The 6-gal aluminum kettle arrived, and the partial-mash saison from it;'s first brew is happily churning away in the basement. Many thanks, the kettle looks like it'll work great for smaller batches on my glass stovetop.

If you could come up with a nice housing for the element to shield the wires/connections from liquid that would be "plug n play" enough for 99% of people. Let them simply connect 3 wires to a H/D extension cord and just about anyone can do that. Something that easily affixes to cover the element base yet is 99.9% water-tight. Perhaps if the coupler were also threaded on the outside then a PVC cap with a cord-grip could thread right on, voila.

There are many easy ways to cover the connection from JB Weld and a PVC coupling to more elaborate electrical boxes to simple heat shrink tubing.

I'd definitely agree that the BK just needs to be on/off and powerful enough to get a rolling boil going. That can be really simple. However, I'd think you'd want your HLT to have a bit more sophistication since strike temperature matters. If you're recirculating, that kind of control becomes even more important.Something that I think many people don't understand is that having electric elements doesn't REQUIRE a sophisticated controller, etc. Mine are simply elements with glorified extension cords running to the wall outlets. Yeah, I don't have precision control, but I'm using them for HLT and BK...why do I need control there again? I've brewed a dozen batches with this setup and the selling point for me was that I could do it in the basement, which I can't do with propane and no stove is gonna heat 10g of wort.

It's not as intimidating as it seems, is all I'm saying.

I'd definitely agree that the BK just needs to be on/off and powerful enough to get a rolling boil going. That can be really simple. However, I'd think you'd want your HLT to have a bit more sophistication since strike temperature matters. If you're recirculating, that kind of control becomes even more important.

Even if you didn't want to make it completely assembled, a "kit" that had the parts all included and suggested assembly directions would make me bite, then if it isn't wired right and I burn my house down it would be on me i am assuming. Alternately a suggested addon list with items that are also available separately from your site that I could add in for the same shipment, and said directions would work for me. I just hate going through 5 different vendors, hoping that when I can't find the right piece that my guess at a like part will still work, and I usually give up, especially on electrical things. This is the main reason I never made a brutus 10 (no interest in trying to make the control panel and nobody sells reasonable priced models) and haven't done electric brewing yet (getting the parts for the element are too dicey for me).

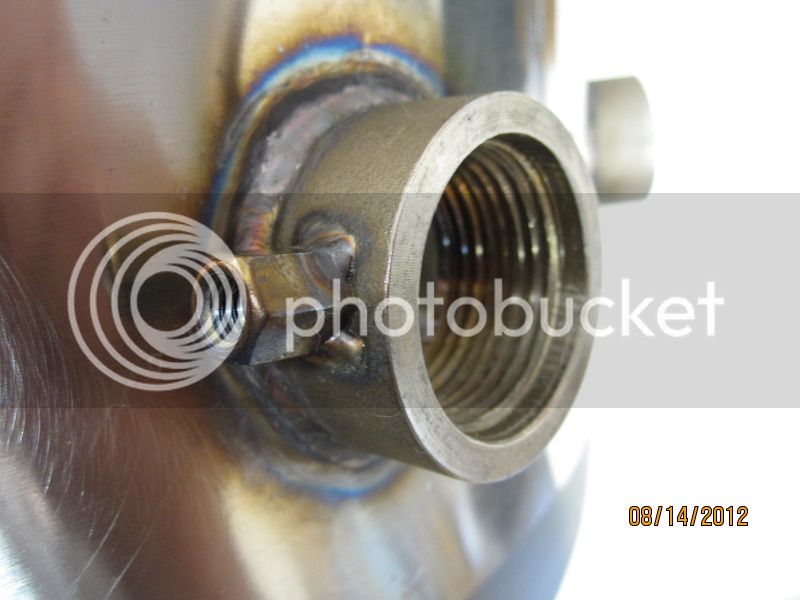

Sorry to muddy-up your thread, Spike. Kudos on the coupler though. I had to drill another hole in my HLT for the ground wire...something I wasn't happy about.

Idiot question on that electric coupler.

Can that be welded on from the outside only?

I've built my own RIMS, I'm super handy, but I'm not a welder. I've been thinking of converting an uncut keg into a still. I was wondering if I popped a hole in a keg with our taking the top off, if that coupler could be welded in place. I know nothing about welding so the answer might be no. If its yes, I could build a sweet electric still.

Any advice is appreciated.

Idiot question on that electric coupler.

Can that be welded on from the outside only?

I've built my own RIMS, I'm super handy, but I'm not a welder. I've been thinking of converting an uncut keg into a still. I was wondering if I popped a hole in a keg with our taking the top off, if that coupler could be welded in place. I know nothing about welding so the answer might be no. If its yes, I could build a sweet electric still.

Any advice is appreciated.

If you could come up with a nice housing for the element to shield the wires/connections from liquid that would be "plug n play" enough for 99% of people. Let them simply connect 3 wires to a H/D extension cord and just about anyone can do that. Something that easily affixes to cover the element base yet is 99.9% water-tight. Perhaps if the coupler were also threaded on the outside then a PVC cap with a cord-grip could thread right on, voila.