beren

Well-Known Member

Want to detect a leak? Use a co2 monitor. Won’t matter what the flow rate is if it’s in an enclosed space the numbers will build.

Want to detect a leak? Use a co2 monitor. Won’t matter what the flow rate is if it’s in an enclosed space the numbers will build.

That meter needs roughly .1 lpm to show a flow. That would be a monstrous leak ime...I saw this years ago and haven't thought about it until just now so I looked it up;

https://www.ontariobeerkegs.com/micro-dbl-inline-leak-detector.htmlI'm wondering if one of those kegland FOB detectors could be modded to do the same thing?

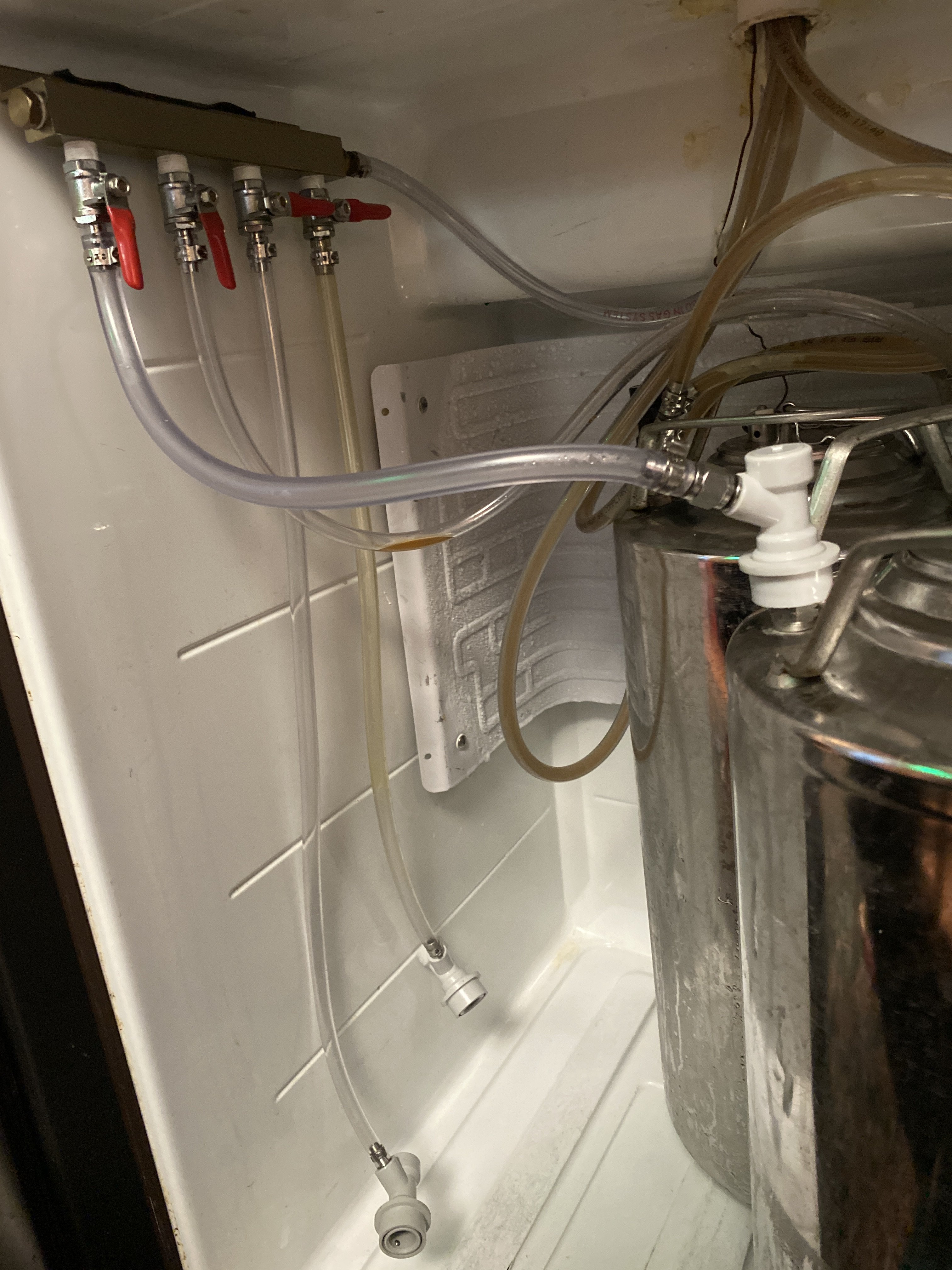

You, know you've got beer in your gas line, yes?Since someone had to blow up my pic and point out the band clamps I hadn’t gotten to yet. Got off my azz and finished

This gauge will measure 100-1000 mL/minute (.1 - 1.0 L/min). Most connect CO2 at night and find an empty bottle in the morning. Some math; a 5lb tank hold 300 liters of CO2. If it empties in 12 hours, 300 liters in 12 hours is 25 liters/hr which is .416 liters/min which this gauge would detect. If it took 24 hours to empty that would be .21 L/m which this gauge would also detect.Good idea!

But for leak detection a much smaller flow range is needed, such as 0.01 l/min, or perhaps you'd get away with 0.1 l/min.

Thanks for the calculations, a 0.1 - 1.0 l/min gauge will show those common, slow leaky flow rates. Yes!This gauge will measure 100-1000 mL/minute (.1 - 1.0 L/min). Most connect CO2 at night and find an empty bottle in the morning. Some math; a 5lb tank hold 300 liters of CO2. If it empties in 12 hours, 300 liters in 12 hours is 25 liters/hr which is .416 liters/min which this gauge would detect. If it took 24 hours to empty that would be .21 L/m which this gauge would also detect.

It was just filled@WesBrew

How much CO2 is left in the cylinder?

I've read, but not confirmed myself, some regulators will exhibit output pressure rise as the cylinder/supply/inlet pressure drops.

It was just filled

Still would be nice to have an inline detector though... I was hoping some mad scientist on here might bite.@Broken Crow ,I'm as to hear you've been regaining mental function, and hope the improvement continues.

My intuition is that a CO2 detector would do the trick if the leak was in a small enclosed space (keezer/kegerator). Less likely to succeed in a kitchen or garage because of how quickly gases mix.

No DIY required, as there are fairly cheap detectors out there.

Are we talking in-line air lock?I think a solid gas leak detector would use a vertically-oriented in-line sight glass filled part way with water - like a bubble gauge, only larger. Connected to the output of a regulator, even the tiniest system leak would show up...

Cheers!

This could be a genius innovative answer. Needs to hold pressure too though, yes?