BrewingWisdom

Well-Known Member

Brewing Date 27/10 /2022

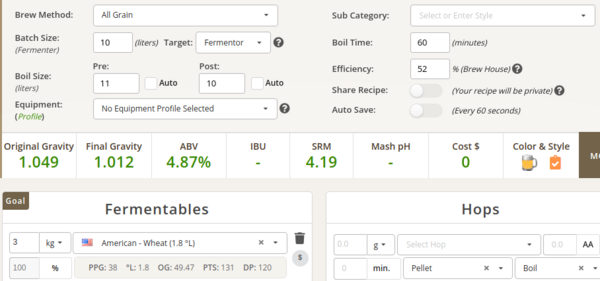

Mash Bill :100% Malted Wheat 3kg

Hops:Hallartau Hersbucker Pellets

Yeast:CS31 Angels Ale Yeast

Batch Size 10 litres

Original Gravity:1.049

Final Gravity :1.000

Abv= 6.4%

Nose:-

Very estery,fruity aroma with citrus notes of hops. No hints of alcohol on nose.

Taste:-

Malty , very bitter (guess I used more hops than I should.

Appearance:

Kind of cloudy (I guess because it's 100% wheat) and the head was quite big.

The carbonation is very strong. The foam runs out when i opened my bottles.

I used jaggery as a priming sugar. Jaggery is basically a pure sugar cane juice in a solid concentrated form. Its used in the indian subcontinent.

BackGround

My journey of homebrewing a beer started in March this year. After lots of learning, reading online ,and spoiling three batches in a row I finally succeeded in my fourth attempt.

Oh and that waiting for months to get the required equipment from china.

Why I succeeded this time?

As a all grain brewer (that's the only option I have)initially I struggled with malting. But this time with enough and equal acrospire length of grains and drying the grain in the air (yea that's a wind malt) I finally succeeded. Previously I either got mold in my grain or destroyed it's diastatic potential by heating it too much in the oven during the drying and kilning stage.

My advise to the ones learning the malting process is to move your grains after every 2 hours , keep them moist by some kind of water spray device(I used the hand water sprayer) for the initial four days. Just dont get lazy after the initial soaking. And dry it under some wind. With too much heat you can end up destroying its diastatic potential.

I want to help everyone here but a

big thanks to @bracconiere and @IslandLizard both of you really helped me a lot.

Specially @bracconiere you were always there for me for answering my questions. Without your help and support this success was simply not possible.

I actually find my product better than all the super expensive commercial beers I bought from the black market.

I am drinking my delicious wheat beer with a glass in right hand and showing a big middle finger of a left hand to those who banned it

Cheers

Mash Bill :100% Malted Wheat 3kg

Hops:Hallartau Hersbucker Pellets

Yeast:CS31 Angels Ale Yeast

Batch Size 10 litres

Original Gravity:1.049

Final Gravity :1.000

Abv= 6.4%

Nose:-

Very estery,fruity aroma with citrus notes of hops. No hints of alcohol on nose.

Taste:-

Malty , very bitter (guess I used more hops than I should.

Appearance:

Kind of cloudy (I guess because it's 100% wheat) and the head was quite big.

The carbonation is very strong. The foam runs out when i opened my bottles.

I used jaggery as a priming sugar. Jaggery is basically a pure sugar cane juice in a solid concentrated form. Its used in the indian subcontinent.

BackGround

My journey of homebrewing a beer started in March this year. After lots of learning, reading online ,and spoiling three batches in a row I finally succeeded in my fourth attempt.

Oh and that waiting for months to get the required equipment from china.

Why I succeeded this time?

As a all grain brewer (that's the only option I have)initially I struggled with malting. But this time with enough and equal acrospire length of grains and drying the grain in the air (yea that's a wind malt) I finally succeeded. Previously I either got mold in my grain or destroyed it's diastatic potential by heating it too much in the oven during the drying and kilning stage.

My advise to the ones learning the malting process is to move your grains after every 2 hours , keep them moist by some kind of water spray device(I used the hand water sprayer) for the initial four days. Just dont get lazy after the initial soaking. And dry it under some wind. With too much heat you can end up destroying its diastatic potential.

I want to help everyone here but a

big thanks to @bracconiere and @IslandLizard both of you really helped me a lot.

Specially @bracconiere you were always there for me for answering my questions. Without your help and support this success was simply not possible.

I actually find my product better than all the super expensive commercial beers I bought from the black market.

I am drinking my delicious wheat beer with a glass in right hand and showing a big middle finger of a left hand to those who banned it

Cheers

Attachments

Last edited:

i SO need to brew to celebrate!

i SO need to brew to celebrate!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)