Feb 07 2017 00:27:41 Resetting controller to factory defaults

Feb 07 2017 00:27:43 Controller debug message: INFO MESSAGE 15: EEPROM initialized

Feb 07 2017 00:28:26 Installed devices received: []

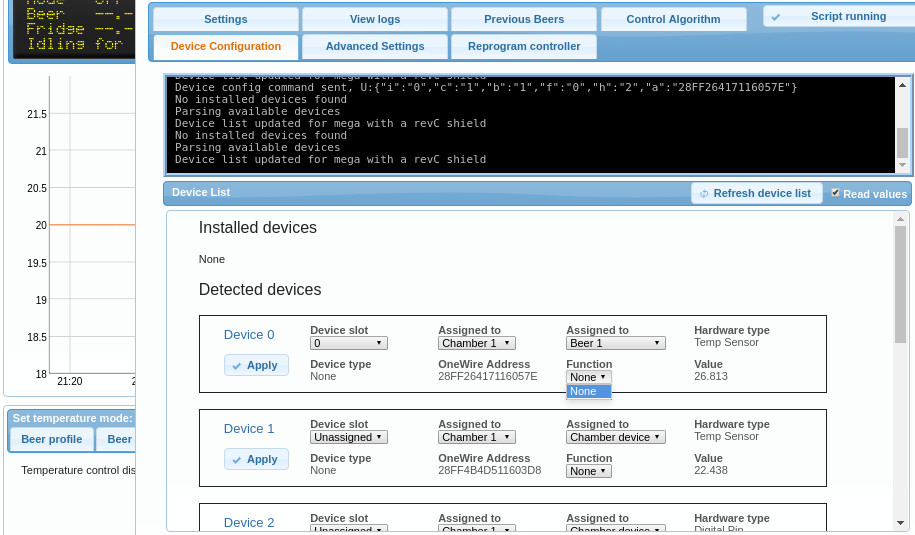

Feb 07 2017 00:28:28 Available devices received: [{"a": "28FF26417116057E", "c": 1, "b": 0, "d": 0, "f": 0, "i": -1, "h": 2, "j": 0.0, "p": 58, "t": 0, "v": 26.5}, {"a": "28FF4B4D511603D8", "c": 1, "b": 0, "d": 0, "f": 0, "i": -1, "h": 2, "j": 0.0, "p": 58, "t": 0, "v": 22.125}, {"c": 1, "b": 0, "d": 0, "f": 0, "i": -1, "h": 1, "p": 2, "t": 0, "x": 1}, {"c": 1, "b": 0, "d": 0, "f": 0, "i": -1, "h": 1, "p": 5, "t": 0, "x": 1}, {"c": 1, "b": 0, "d": 0, "f": 0, "i": -1, "h": 1, "p": 6, "t": 0, "x": 1}, {"c": 1, "b": 0, "d": 0, "f": 0, "i": -1, "h": 1, "p": 59, "t": 0, "x": 1}, {"c": 1, "b": 0, "d": 0, "f": 0, "i": -1, "h": 1, "p": 4, "t": 0, "x": 1}]

Feb 07 2017 00:28:47 Device updated to: {"i":0,"t":0,"c":0,"b":0,"f":0,"h":0,"d":0,"p":0}

Feb 07 2017 00:28:52 Installed devices received: []

Feb 07 2017 00:28:54 Available devices received: [{"a": "28FF26417116057E", "c": 1, "b": 0, "d": 0, "f": 0, "i": -1, "h": 2, "j": 0.0, "p": 58, "t": 0, "v": 26.5}, {"a": "28FF4B4D511603D8", "c": 1, "b": 0, "d": 0, "f": 0, "i": -1, "h": 2, "j": 0.0, "p": 58, "t": 0, "v": 22.125}, {"c": 1, "b": 0, "d": 0, "f": 0, "i": -1, "h": 1, "p": 2, "t": 0, "x": 1}, {"c": 1, "b": 0, "d": 0, "f": 0, "i": -1, "h": 1, "p": 5, "t": 0, "x": 1}, {"c": 1, "b": 0, "d": 0, "f": 0, "i": -1, "h": 1, "p": 6, "t": 0, "x": 1}, {"c": 1, "b": 0, "d": 0, "f": 0, "i": -1, "h": 1, "p": 59, "t": 0, "x": 1}, {"c": 1, "b": 0, "d": 0, "f": 0, "i": -1, "h": 1, "p": 4, "t": 0, "x": 1}]

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)