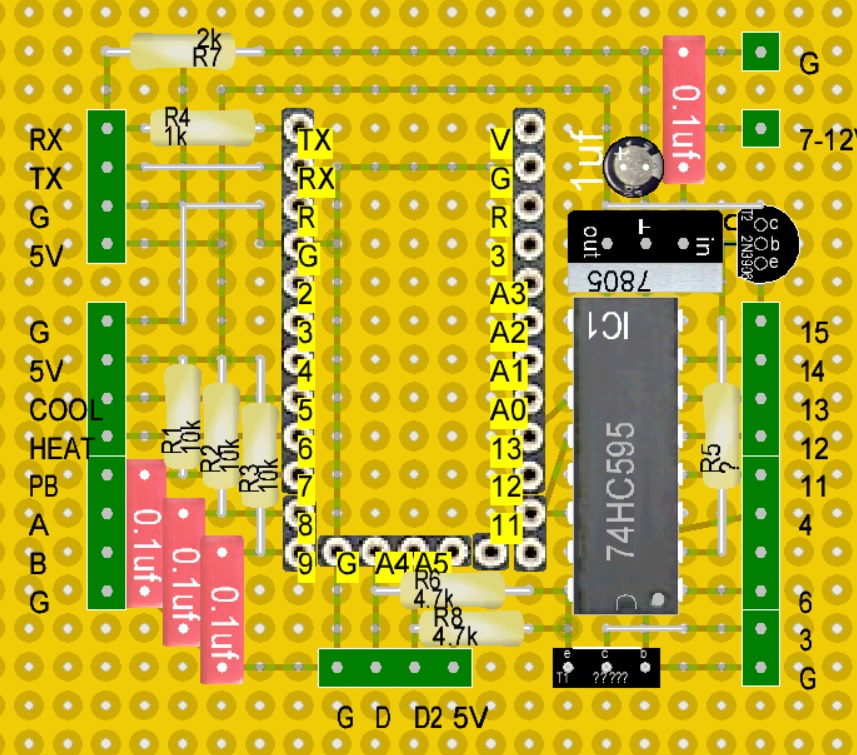

What we know:

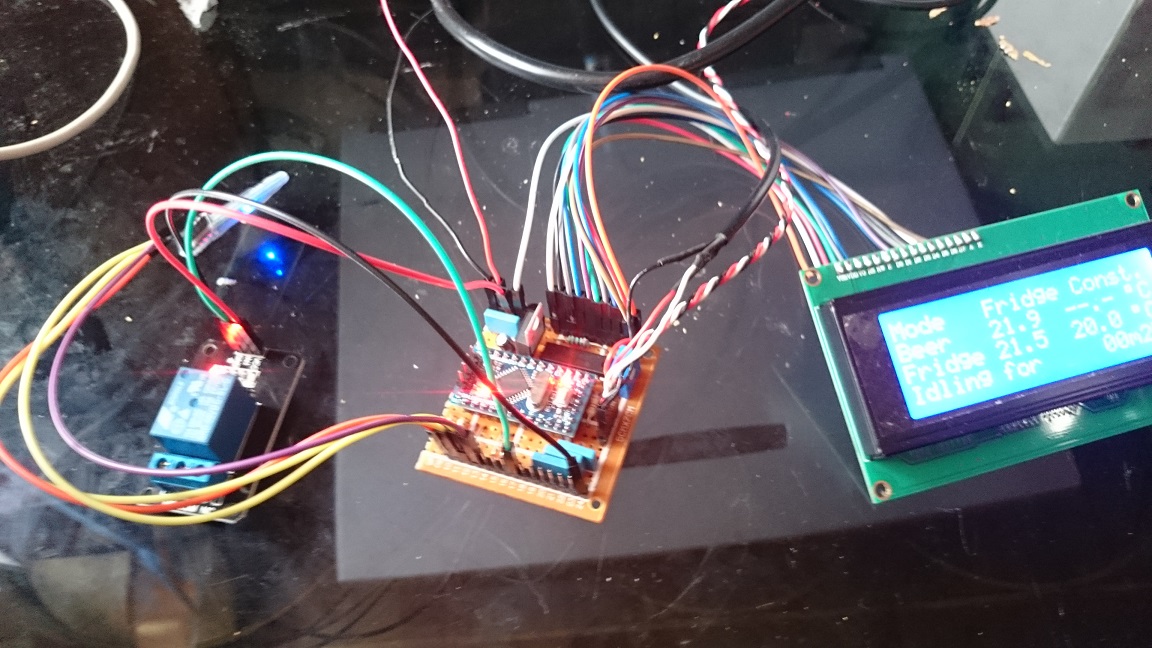

- UNO green LED on: power good

- UNO amber LED on: script ran far enough to turn on IO13 (to the "blink" LED).

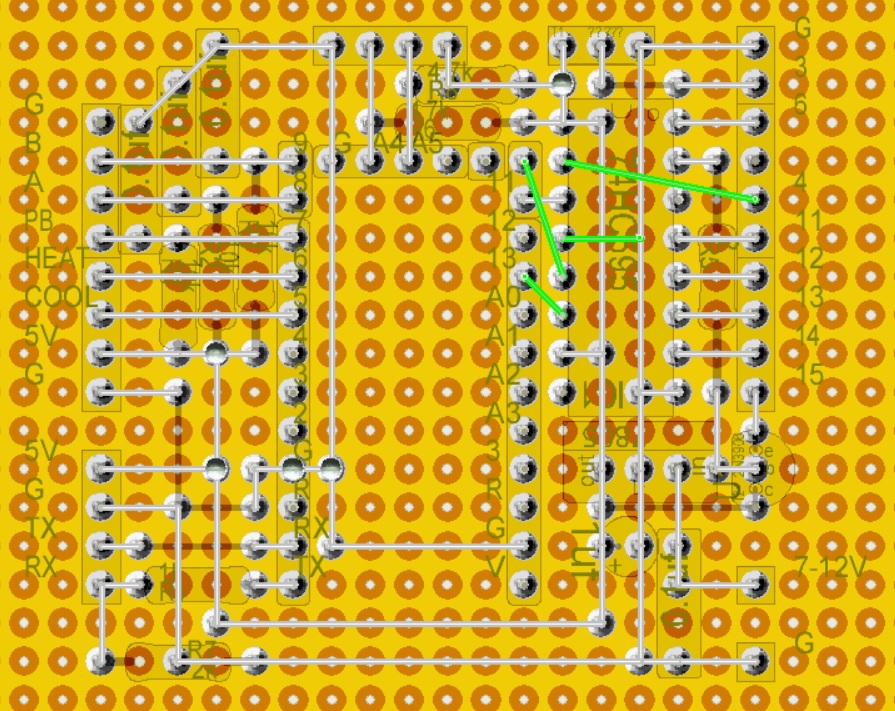

- BrewPi host can't talk to the Uno suggests the comm lines aren't working.

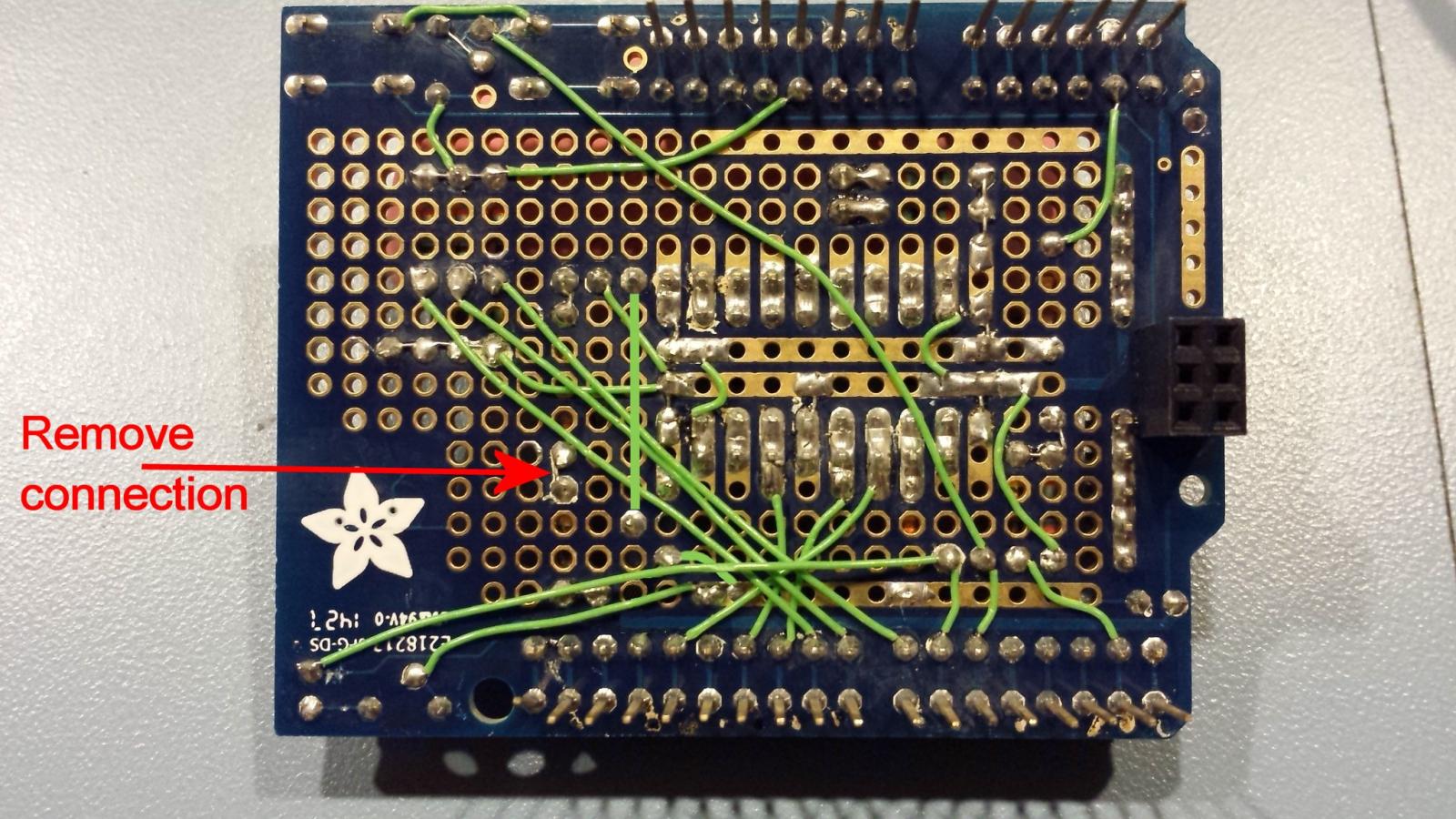

So, unsolder the wire from IO1, make sure the IO 0 and IO 1 pins aren't shorted to any neighbors, then see what happens....

Cheers!

- UNO green LED on: power good

- UNO amber LED on: script ran far enough to turn on IO13 (to the "blink" LED).

- BrewPi host can't talk to the Uno suggests the comm lines aren't working.

So, unsolder the wire from IO1, make sure the IO 0 and IO 1 pins aren't shorted to any neighbors, then see what happens....

Cheers!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)