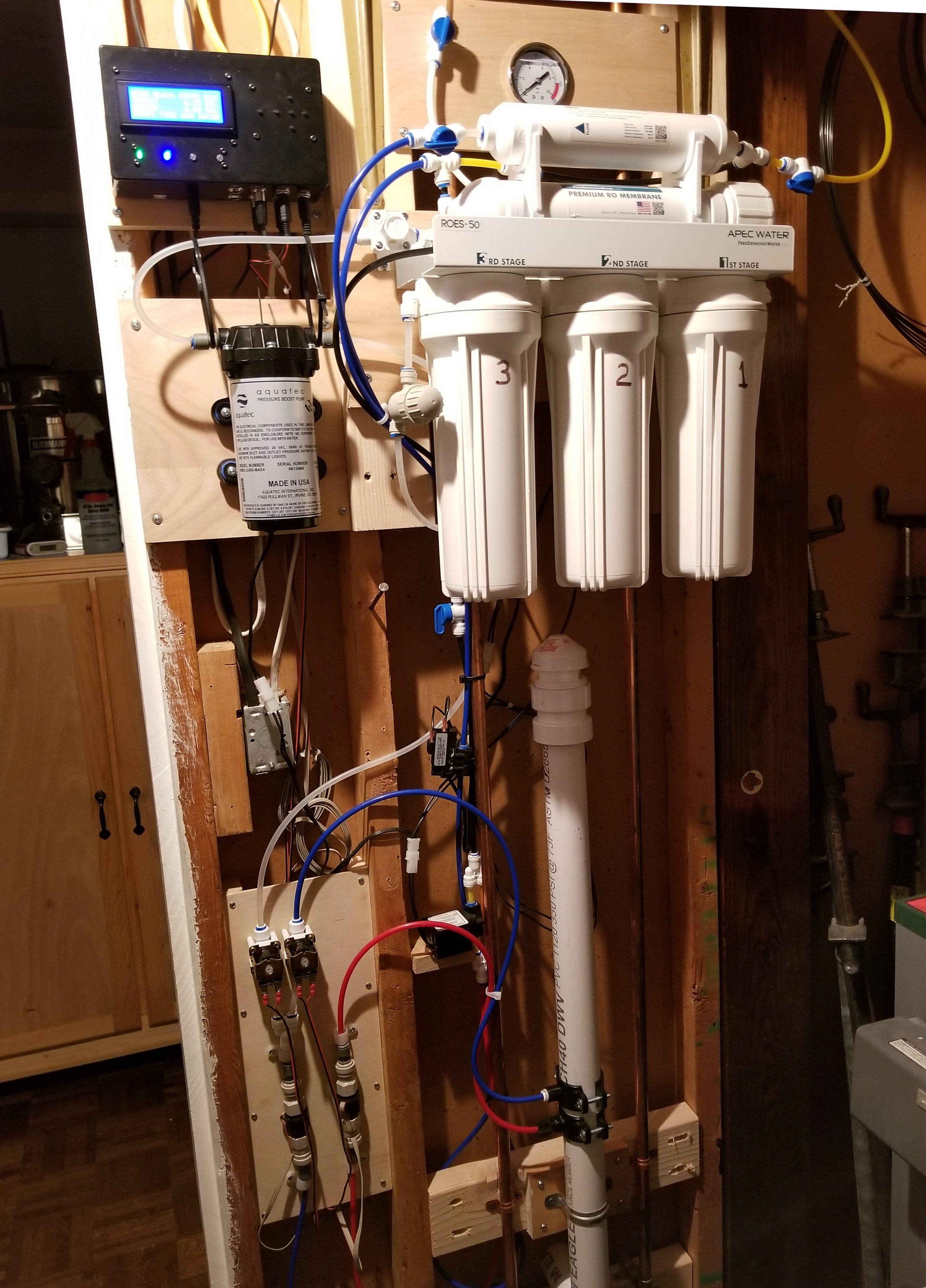

I'm calling it "RO Buddy" for now, and it's for managing my reverse osmosis system. I can program it to fill my brew kettles with the prescribed volume starting whenever I want (within a week), and I can also program it to run the RO system to dump any specific volume (on a 1 to 7 day period) to keep the membrane from fouling from lack of use.

I use an inexpensive ds3231 rtc module to offload time-keeping from the Arduino to preserve tick-count fidelity, and

so far it'll still run on an Uno as well as a Mega2560. That pic has one of both, the Mega using an I2C display and the UNO a 4-bit parallel. It has a dual relay module to activate solenoids to either supply brewing liquor or dump RO product (for the membrane maintenance function). It'll sound an obnoxious alarm if water is flowing when it shouldn't or meters aren't spinning when they should, and if either is ignored long enough it'll scram the solenoids and keep making noise.

I'm planning on adding effluent metering so I can calculate efficiency and then adding a ds18b20 on the feed-water side as temperature is important wrt membrane performance. I expect at that point to have run out of ram on the UNO and will truncate further development on that platform, never mind if I follow through on coming up with a TDS function on the in and out water...

View attachment 619912

I've had the proto running for a few weeks and it has found two cool bugs (one was a lulu

) and a couple of meh ones. There's nothing like initiation by fire to bring out unconsidered behavior as well as sloppy coding

View attachment 619918

View attachment 619918

This system currently runs at a reliable 50 gpd but I'll be upgrading to 100 gpd (basically a membrane change, higher capacity pump and higher flow capillary restrictor).

Anyway...this is what happens to a techno-dweeb on the cusp of retirement with lots of toys and spare parts to play with

Cheers!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)