CaliforniaJones

Member

- Joined

- May 2, 2014

- Messages

- 12

- Reaction score

- 2

Dam I just purchased 2 sight glasses; If I only saw this two days ago I could have saved some $$.

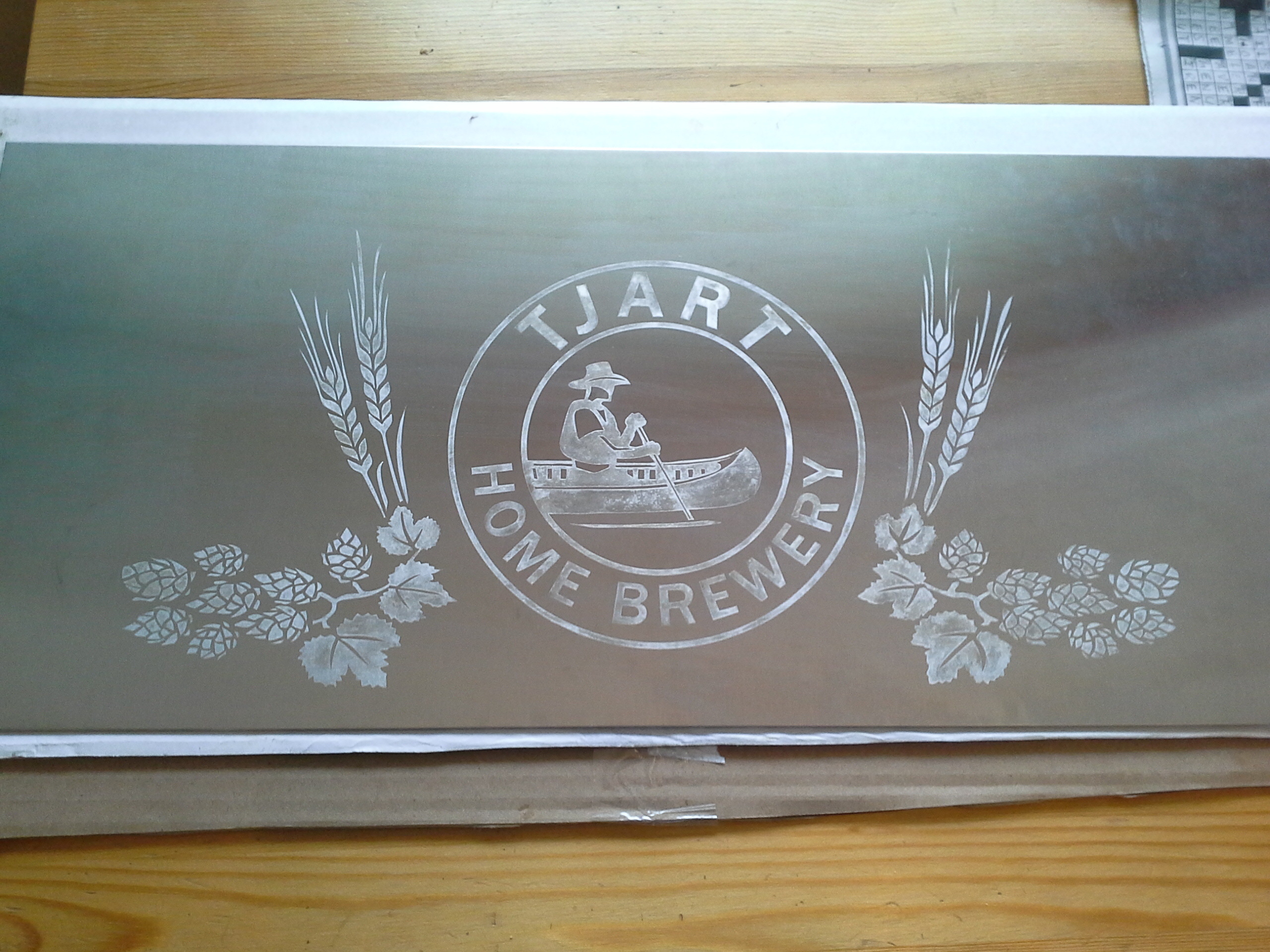

Oh well I'm going to try this on the outside of my kegs if I can find a stencil of some Hops or a cool logo of some sort.

Im curious, How are sight glasses that arent specifically maunufactured for your kettle calibrated?

I was thinking of buying a sight glass, assuming generic ones arent marked, and etching the kettle next to the glass on the outside.

--------------------------------------------------------------------------

SS Brewbucket: McMullen 85/-

Cornie #1: Auld Saxon D (lagering)

Cornie #2 Belgian Wit

Bottled: McMullen 85/-

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)