You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How long does your brew day take with your electric systems?

- Thread starter zacster

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I have a 3300 W brauheld pro and use it to make 8-10 gal batches. Normally it takes me around 6 hours to get it into the fermenter. I can't use full power because if anyone else plugs anything like a hairdryer or some machine the power goes out... So I keep it at 3000 maximum to reach a boil with the recirculation pumps on. This is with a 1 hr mash and 1 hr boil + cleaning and sanitizing fermenter and etc...

I see many grind their grist a day in advance.

This I understand spreads the brewing time more comfortably, but would you grind your coffee beans one day in advance, or your pepper, or the cheese for your spaghetti, or your nutmeg?

Meditate, people, meditate

This I understand spreads the brewing time more comfortably, but would you grind your coffee beans one day in advance, or your pepper, or the cheese for your spaghetti, or your nutmeg?

Meditate, people, meditate

As with coffee, I grind immediately before adding it to water.I see many grind their grist a day in advance.

This I understand spreads the brewing time more comfortably, but would you grind your coffee beans one day in advance, or your pepper, or the cheese for your spaghetti, or your nutmeg?

Meditate, people, meditate

Yea same. I grind it as im waiting for the mash water to heat upAs with coffee, I grind immediately before adding it to water.

Four hours with a GF G30, strike water is hot via a delayed timer, grains are from a kit but fresh two days prior. Sometimes cleanup will add another 30, but I try to clean while I wait on something else. I try to brew every week or two for a 4 tap kegerator, but only two of us drinking beer we have plenty. We like to have two IPA’s up at all times.

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

My village near Chicago gets soft water from Lake Michigan. For chlorine I add 1 campden tablet before throwing the grist in..... I noticed an improved taste.I should try the hot water as it is about 130 in my house. It would kick start the process. I'm always a little shy about using hot water from the tap and the only thing I currently use it for cooking is when I use my sous vide, which never actually touches the food. I have a relatively new hot water heater so maybe the crud buildup hasn't happened yet.

duffman13jws

New Member

- Joined

- Feb 9, 2021

- Messages

- 2

- Reaction score

- 2

I'm running a 240v digimash, and usually hit around 4.5hrs from setting strike temp on the controller to cleanup. I mill my grains and do my water adjustments while it heats, and I have a pump-driven whirlpool which cuts my cooling times significantly.

The biggest benefits are the predictability, and the ability to walk away. You'll never overshoot a strike temp or a mash step with a controller like you can on propane, and electric heating times are incredibly consistent from batch to batch so you can functionally set a timer and come back when the wort is in the low 200s to babysit through the hot break.

The biggest benefits are the predictability, and the ability to walk away. You'll never overshoot a strike temp or a mash step with a controller like you can on propane, and electric heating times are incredibly consistent from batch to batch so you can functionally set a timer and come back when the wort is in the low 200s to babysit through the hot break.

Last edited:

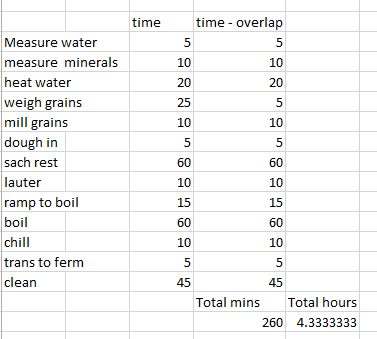

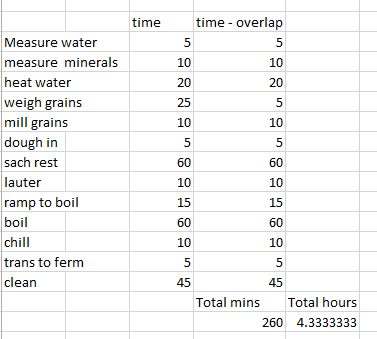

Here's a quick "back of the napkin" spreadsheet estimate of the minimum time I can imagine. This assumes you do everything on the brew day (vs adding minerals, measureing/milling grain etc ahead of time). Unless I cut corners, I think this is probably within 30 mins of the minimum:

No shorter than my normal brew day. If anything, it's longer because like mentioned above, I'm way "less attentive." I set up the night before and then wake up, flip a few switches, and go back to bed. The strike water sits at the correct temperature until I'm ready. Then when the wort is in the kettle, I set the temperature a few degrees below boiling and go do something else. It's been known to sit there for longer than necessary, unlike waiting for the boil and boil over on my stove. And then there is the hop stand. I can take my time, holding the desired temperature.

10 minutes for lauter? This is way too quick.Here's a quick "back of the napkin" spreadsheet estimate of the minimum time I can imagine. This assumes you do everything on the brew day (vs adding minerals, measureing/milling grain etc ahead of time). Unless I cut corners, I think this is probably within 30 mins of the minimum:

View attachment 725053

10 minutes for lauter? This is way too quick.

I batch sparge

I brewed Friday and planned on timing it but then I dropped a quarter sack of Vienna malt on the floor and I had to spend time cleaning that up and I had to boil for an extra half hour to get the gravity up, so maybe next time!

I had to boil for an extra half hour to get the gravity up

That sucks, but still, good job - when my gravity is low I just go for it. I figure no big deal then regret it ever after. Not sure why I do that to myself but I do at least once a year I think.

That sucks, but still, good job - when my gravity is low I just go for it. I figure no big deal then regret it ever after. Not sure why I do that to myself but I do at least once a year I think.

There were only bittering hops in this beer, so a longer boil wasn't much of an issue.

I’m at 5 hours with a 240v system. Probably shaved off 45 minutes because everything is close to brew area inside , quicker ramp times.

brewing is more enjoyable now that I’ve started doing split brew days.

At night I’ll mill, set up hlt water, run the mash and sparge into kettle. Cleanup. Next morning turn on kettle , start boil. Go have breakfast n coffee. Finish boil, whirlpool , chill, fill fermenter. Heat up water in kettle to flush pump , plate chiller n herms coil. Enjoy the rest of the day

brewing is more enjoyable now that I’ve started doing split brew days.

At night I’ll mill, set up hlt water, run the mash and sparge into kettle. Cleanup. Next morning turn on kettle , start boil. Go have breakfast n coffee. Finish boil, whirlpool , chill, fill fermenter. Heat up water in kettle to flush pump , plate chiller n herms coil. Enjoy the rest of the day

Roughly 3 hours from start to finish. I scaled down from 5 gallon batches to 2.5 gallons. Easier to manage. Use BIAB in a gigawort electric kettle. 30 minute mash, 30 minute boil. No chill into corny keg until it's hit fermenting temp.

I just purchased the gigawort and will be doing the same - 2.5g BIAB. How's the 30 min mash coming out? I've never done a 30 min mash

- Joined

- Dec 4, 2020

- Messages

- 16

- Reaction score

- 10

I've never noticed much issues with shortened mashes. I probably should plan to do them as I get distracted all the time or wait for things to come up to temp and it turns out to be 45 min anyway.

I usually do short boils for "bonus" beers (second runnings and what not) without any noticeable difference. I'm hesitant to do them regularly as it seems not worth the risk. I know some NEIPA lovers who do short boils exclusively.

I usually do short boils for "bonus" beers (second runnings and what not) without any noticeable difference. I'm hesitant to do them regularly as it seems not worth the risk. I know some NEIPA lovers who do short boils exclusively.

Chetbrews

Well-Known Member

- Joined

- Dec 25, 2016

- Messages

- 50

- Reaction score

- 86

Overall it's good, you lose efficiency with a short mash, but I have been focused on brewing session beers so I'm fine with it. I tend to average around 1.038-1.040 pre-boil gravity with 5 lbs of base grain with 14 liters of water at 30 minutes. I don't stir the mash or have the heat on during that time. I also don't do any sparging.I just purchased the gigawort and will be doing the same - 2.5g BIAB. How's the 30 min mash coming out? I've never done a 30 min mash

I did two batches on a 10.5 Foundry running 240 this past weekend with “planned” 60 minute mash and boil schedules. I set up most stuff the previous night and used the delay to start warming up the water at 4 on Saturday morning with the intent of getting out into the garage at 5. Long story short, I didn’t start mash timer until a little after 6. Had batch in fermenter finishing up rest of chill from 72 down to 68 by 1030.

Decided to just the second batch I was going to do on Sunday since it was still fairly early in the day. Think I finished cleaning and all that before 5 that evening. Was tired and dragging my feet a bit after but was still able to go to a “drive in” movie event later that evening.

Decided to just the second batch I was going to do on Sunday since it was still fairly early in the day. Think I finished cleaning and all that before 5 that evening. Was tired and dragging my feet a bit after but was still able to go to a “drive in” movie event later that evening.

- Joined

- Feb 16, 2012

- Messages

- 4,647

- Reaction score

- 7,073

- Location

- At home, in the brewery in Maryland.

Same equipment and very similar timeline, though I usually do a 1+30 step mash and 75 minute boil. Following boil and chill I do a 30 minute whirlpool/hopstand before pumping to the fermenter and pitching/oxygenating, so I don't get down to the heavy lift (cleaning) until the wort is in the fermenter.I use a 20litre Braumeister, usually doing 23litre (in the fermenter) batches. I fill the system the night before (and my 8 litre sparge water pot). On brewday I start at 7am (switch on system to start heating) it is usually in the fermenter by 12:00/13:00 depending on mash steps and length of boil. So maximum 6 hours for the brewday and 1 hour to clean up.

Six and a half to seven hours on a Spike 20 Gallon three vessel system. This is from start (fill the HLT and turn it on) to end (put everything away in a cleaned and RTG for next brew day). It does take about an hour or perhaps a little more at the start to heat up the MT to strike temps, and then takes another 20-30 minutes getting the MT to mash out temps. All this is time spent drinking coffee, reading the newspaper ("What's a newspaper?", says the millennial) or organizing my day. The "real" brew day, i.e. starting from when the MT is at strike temp, is about 5.5-ish hours.

sicktght311

Well-Known Member

- Joined

- Oct 16, 2018

- Messages

- 686

- Reaction score

- 304

FYI, with my 120v system, late last week I needed to knock out an evening brew session, so I turned it on at 530 pm with 90-100 degree water already in the kettles (I filled and heated it up to around 180 the night before and shut everything down), and i was done brewing by 1030pm. 1ish hour to heat up to strike temp, 1 hour mash, 35 minute quick sparge, 45 minute ramp to boil, 1 hour boil, 5 minutes to chill to whirlpool temp, 30 minute whirlpool hops, then another 10 minutes to final knockout to fermenter. Shut everything down and I cleaned up the next day.

zacster

Well-Known Member

I brewed today for the first time since originally posting this and it took 6.5-7 hours beginning to end. Part of the extra time over the usual 6 for me was that I had some whirlpool hops in the recipe, which adds time at the end. I then ran the immersion chiller but that was quick because the water is so cold at this time of year. I also took my time cleaning up although I didn't make as big a mess as usual.

It was my usual BIAB 5g batch on a stove top with a high output burner. It is just enough to hold a boil but is very slow to get things up to temp.

It was my usual BIAB 5g batch on a stove top with a high output burner. It is just enough to hold a boil but is very slow to get things up to temp.

Mac MacFarlane

Well-Known Member

- Joined

- Apr 22, 2020

- Messages

- 82

- Reaction score

- 57

I brew after kids go to bed, usually takes about 4hours on my brewzilla. I clean everything as I go and whatever doesn’t get clean that night I’ll do it the next day.

I use two Mash & Boil units and a typical brew day is 4 1/2 hours.

Nick Poggetti

Well-Known Member

For the past year, I've been brewing at night. Which I never thought I'd do after having kids, because I was always so exhausted.

But I've got things dialed in that my evenings look like this on my 1 vesel e-biag setup. These are all rough-ish amounts.

The great part is the 90ish minutes during the mash just getting the house cleaned up and kids down makes it seem much less time consuming than it really is.,

But I've got things dialed in that my evenings look like this on my 1 vesel e-biag setup. These are all rough-ish amounts.

- ~20 Minutes, the night before. Mill grains, fill up kettle with water, add campden, water additions, acid, etc.

- ~5 Minutes, at any point in the leading hours to brewing, turn the heating element on and let it heat up to strike temp. Set up kettle for mash in.

- ~15 Minutes, mash in, set out anything needed for the batch.

- ~90 Minutes Go eat dinner, get kids down to bed. Pull grain bag if mash timer goes off, or leave it in if I'm lazy

- ~90-120 Minutes, boil, cool, transfer/pitch, clean up. Usually I refill the kettle and let it CIP and heat back to 150 then leave the PBW soaking on the heating element till the next day for a rinse.

The great part is the 90ish minutes during the mash just getting the house cleaned up and kids down makes it seem much less time consuming than it really is.,

Similar threads

- Replies

- 11

- Views

- 869

- Replies

- 26

- Views

- 3K