It took me about year, 20 batches to make beer that was craft quality. At that time I submitted two beers to competition and score "good" and "very good". One more point on each would have moved them to very good and excellent. Since then I generally make very good beer. If I wouldn't buy it I dump it. Five years in, I still dump a batch or two annually, though some of those are failed experiments. Study and practice improves beer. But you also may be judging your own brews too harshly. I was quite surprised the first time my brew club unanimously pronounced my beer very good. Find a homebrew club, go to meetings, get some experienced feedback. And don't give up, you can make great beer.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How long before you made your first real good beer?

- Thread starter jturman35

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Aug 8, 2017

- Messages

- 1,509

- Reaction score

- 1,783

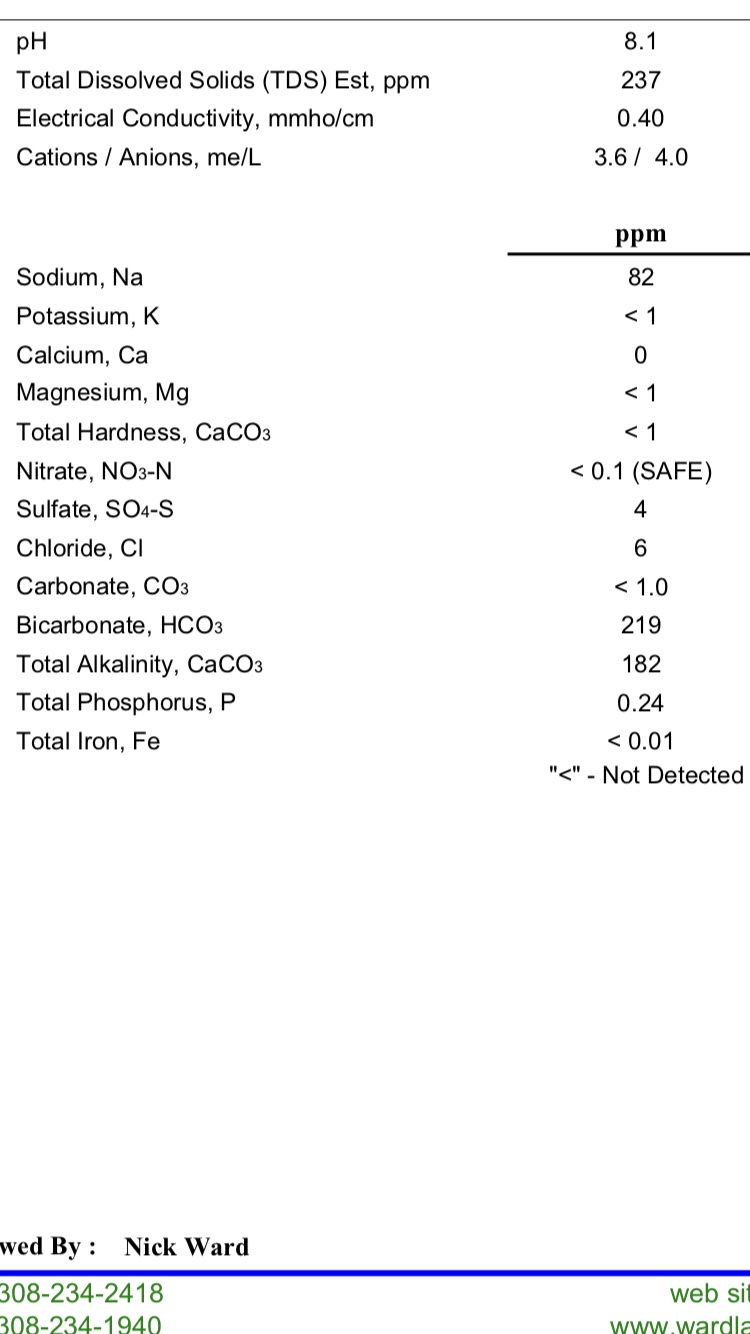

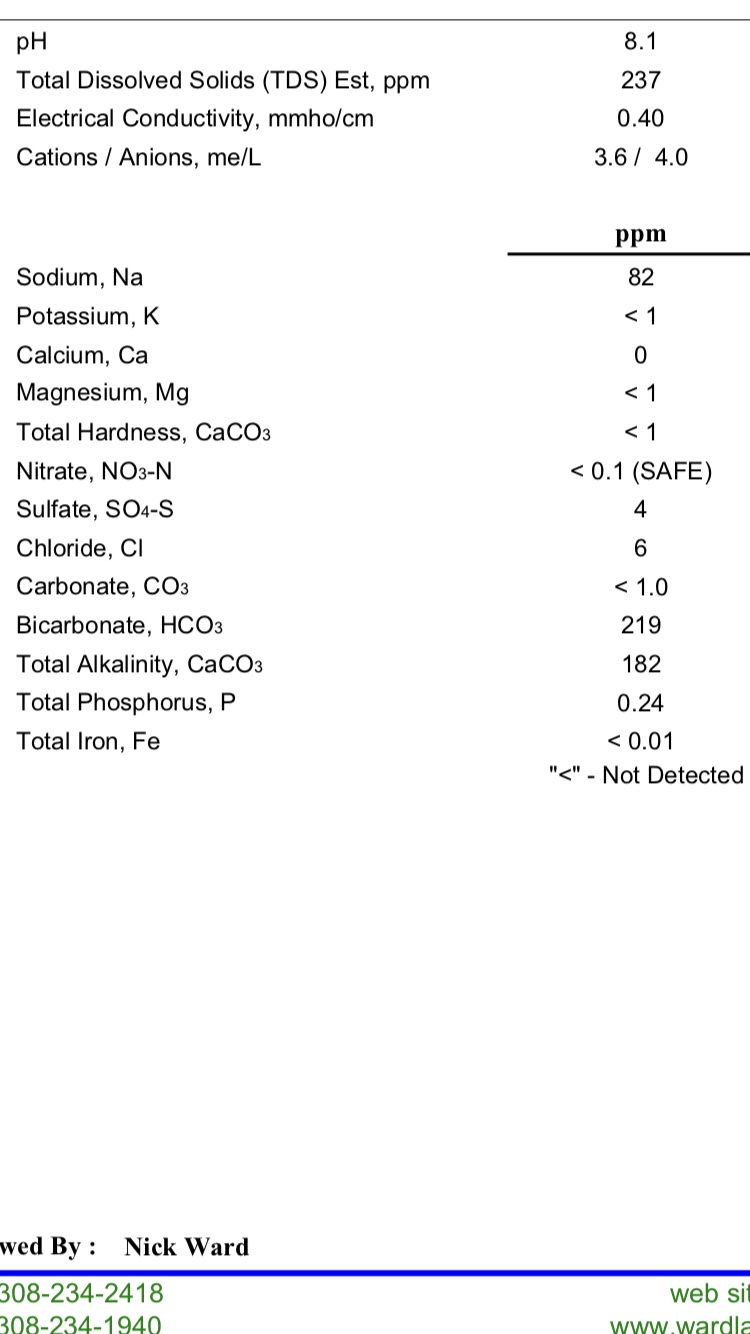

Just got my water report so I hope to start my adjustments soon!

Just got my water report so I hope to start my adjustments soon!

One of the reasons I went to RO was A) Cheep at 1.75/5gallons and B) Starting pH is 7 as opposed to 9 where Austin's water is. Also, the report will vary over the course of a year and after rain events so sticking with a known base water makes sense, at least to me.

Although your water appears much "cleaner" then mine..

That water would be ok for dark beers..... you could basically cut it with 20-40% RO water to get the sodium down, the alkalinity/bicarbonate is good for dark beers, and then add about 1tsp of CaCl per 5 gallons or 1/2 tsp each of CaCl and Gypsum per 5 gallons and you would have a pretty decent profile for dark beers.

However, for light beers like blondes, kolsch, pale ales, IPA's, pilsners and other lagers - that water is going to give you problems. The bicarbonate/alkalinity is going to give you pH problems. The sodium is too high. The easiest solution you are going to have is to use 100% RO water for your light beers and add minerals/acid to get it where you want.

For a generic suggestion in regard to water on your light beers - do the following and see if it makes a difference for you and your concerns.

1.) Use 100% RO water on a batch for mash and sparge water (I use those refill stations you can find at walmart or grocery stores.... and I refill 3 gallon jugs - about .39 cents per gallon when refilling)

2.) add 1 level tsp of gypsum and 1 level tsp of CaCl to each 5 gallons of mash water

3.) add 2ml of lactic acid to 5 gallons of mash water

4.) add 1ml lactic acid to 5 gallon of sparge water

5.) Don't add any of the minerals to sparge water

*** This will get you very much in the range of where you want to be in terms of pH, mineral content, etc. for a light colored beer like a lager, a hoppy pale ale, or a blonde ale. There are certainly more precise ways to tailor this to specific types of beers, but the steps outlined above will get you close enough to tell the difference in a light colored beer.

*** The other issue is chlorine/chloramine in tap water...... when using the RO water for a light beer you are good. But, when using tap water for a dark beer - you have to get chlorine/chloramine out. Campden tablets (1/2 tab crushed up per 5 gallons should do the trick). Chlorine/chloramine in water can result in phenolic beer - spicy/smoky/plastic/bandaid kind of flavors.

- Joined

- Aug 8, 2017

- Messages

- 1,509

- Reaction score

- 1,783

I have a rosemary Pale Ale and a Old Highland Scotch Ale fermenting as I type. Interesting to see which one taste better. The Pale Ale sample at 16days was not bad. The Scotch Ale wasn’t as dark as I’d like so I will have to see. Both had mash PH in the 6.2-6.5 range.

I just ordered John Palmers “How to brew” so I plan on reading a good bit on water chemistry. I do realize for everything changed in water chemistry affects other items as well. I like the simplicity of the BS water profile verses Brunwater. From what little I have read my calcium could be higher. Alkalinity is a tad high. I have lots of learning!

I do BIAB using a COFI basket from BrewBoss so I will have no sparge.

I just ordered John Palmers “How to brew” so I plan on reading a good bit on water chemistry. I do realize for everything changed in water chemistry affects other items as well. I like the simplicity of the BS water profile verses Brunwater. From what little I have read my calcium could be higher. Alkalinity is a tad high. I have lots of learning!

I do BIAB using a COFI basket from BrewBoss so I will have no sparge.

Last edited:

- Joined

- Aug 8, 2017

- Messages

- 1,509

- Reaction score

- 1,783

That water would be ok for dark beers..... you could basically cut it with 20-40% RO water to get the sodium down, the alkalinity/bicarbonate is good for dark beers, and then add about 1tsp of CaCl per 5 gallons or 1/2 tsp each of CaCl and Gypsum per 5 gallons and you would have a pretty decent profile for dark beers.

However, for light beers like blondes, kolsch, pale ales, IPA's, pilsners and other lagers - that water is going to give you problems. The bicarbonate/alkalinity is going to give you pH problems. The sodium is too high. The easiest solution you are going to have is to use 100% RO water for your light beers and add minerals/acid to get it where you want.

For a generic suggestion in regard to water on your light beers - do the following and see if it makes a difference for you and your concerns.

1.) Use 100% RO water on a batch for mash and sparge water (I use those refill stations you can find at walmart or grocery stores.... and I refill 3 gallon jugs - about .39 cents per gallon when refilling)

2.) add 1 level tsp of gypsum and 1 level tsp of CaCl to each 5 gallons of mash water

3.) add 2ml of lactic acid to 5 gallons of mash water

4.) add 1ml lactic acid to 5 gallon of sparge water

5.) Don't add any of the minerals to sparge water

*** This will get you very much in the range of where you want to be in terms of pH, mineral content, etc. for a light colored beer like a lager, a hoppy pale ale, or a blonde ale. There are certainly more precise ways to tailor this to specific types of beers, but the steps outlined above will get you close enough to tell the difference in a light colored beer.

*** The other issue is chlorine/chloramine in tap water...... when using the RO water for a light beer you are good. But, when using tap water for a dark beer - you have to get chlorine/chloramine out. Campden tablets (1/2 tab crushed up per 5 gallons should do the trick). Chlorine/chloramine in water can result in phenolic beer - spicy/smoky/plastic/bandaid kind of flavors.

I’m starting to wonder why I don’t just use RO water on everything and add salts to make the profile I want. Seems like the easiest way to get exactly the water profile you want, no? I mean my water could change from the time I sent the report off to Ward Labs. It seems logical to just use RO water and this way I know almost exactly where I’m starting and then add the minerals using Brunwater. If this is the case do you just enter 0 for all of the minerals and calculate accordingly?

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

if your water changes seasonally really depends on the source. a shallow well and municipal supply from surface water certainly do. however, if you get your water from a deep well, the answer is quite different.I’m starting to wonder why I don’t just use RO water on everything and add salts to make the profile I want. Seems like the easiest way to get exactly the water profile you want, no? I mean my water could change from the time I sent the report off to Ward Labs. It seems logical to just use RO water and this way I know almost exactly where I’m starting and then add the minerals using Brunwater. If this is the case do you just enter 0 for all of the minerals and calculate accordingly?

TheHopfather

Well-Known Member

Both had mash PH in the 6.2-6.5 range.

A mash pH of 6.2 - 6.5 is too high, full stop. You need to adjust with acid to get that pH down into the 5.2 - 5.6 range. The alkalinity of your water is really high, the higher the alkalinity the harder it is to lower the pH into the proper range. I'd try a brew with straight RO water, add some calcium chloride and gypsum back into the water and use a calculator to figure out how much acid to add.

I'd put money making this one change will vastly improve your beer.

TheHopfather

Well-Known Member

It seems logical to just use RO water and this way I know almost exactly where I’m starting and then add the minerals using Brunwater. If this is the case do you just enter 0 for all of the minerals and calculate accordingly?

You make the adjustment on the "Water Adjustment Tab". Set the "Percent Dilution Water" value to 100. That'll let Brun' Water know you are using 100% RO. There is another value to set in the "Sparge Acidification" tab, but since you're using BIAB it shouldn't matter for your setup.

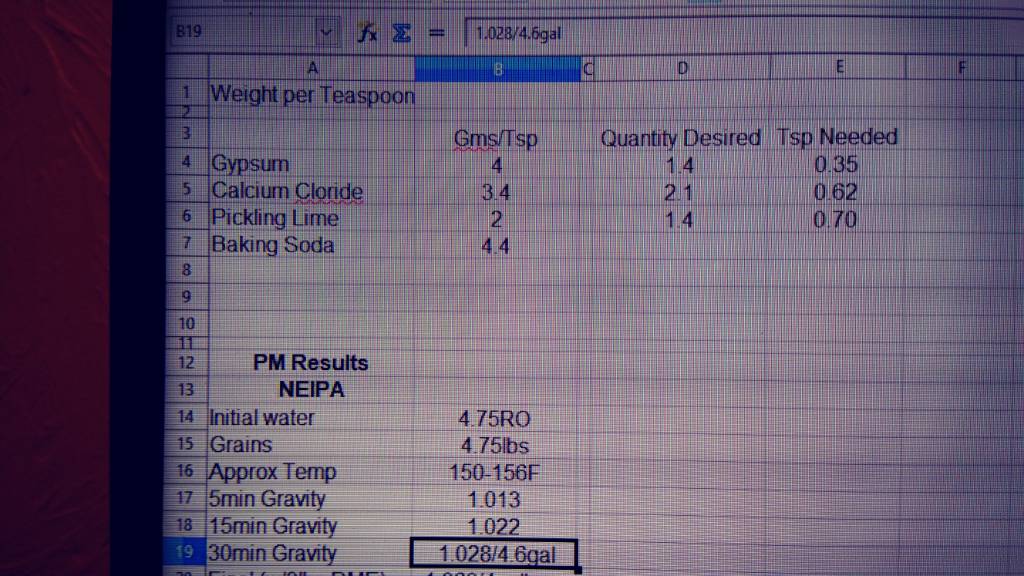

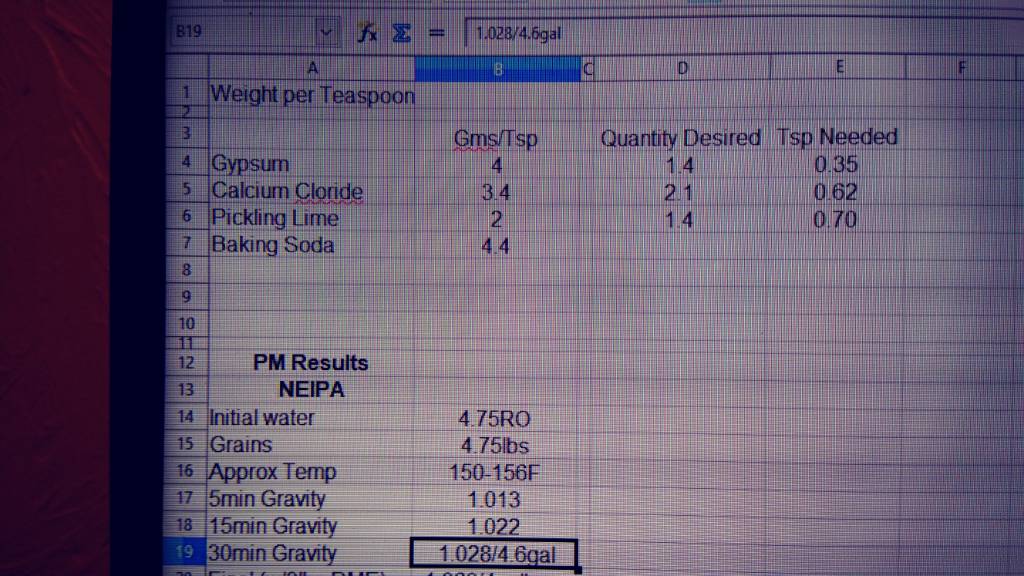

Attachments

I set this up in Open Office to covert from grams to teaspoons. Simple and will get me onto the ballpark.

Manfish

Well-Known Member

I honestly wouldn't be able to say what batch # it was for me. I do know that from when I started, just over 8 years ago, until that 1st one that *I* got excited about, I never had one that I felt was terrible, just others were better. Interestingly enough, I am still that way. Our latest release, "Shiverrr" (a 7% red IPA), almost didn't get released because I was unhappy with it. It is the 2nd AG recipe that I wrote about 7 years ago, yet this is the 1st time it was brewed on the 1BBL system (I had never done above 5 gallons at a time of it). However, the feedback I get from where it is on tap has been really good and that place already wants a 2nd keg of it. Someone above said this would be a "Subjective" answer. That is very true!

Btw, that batch that *I* got excited about wasn't until may of 2015. That same recipe I will be kegging a batch of tomorrow. It is an 8% 2xIPA. The sampler I had was incredible! Our 3xIPA, 12% "R U Ready?!?", will be released on 2/3. Looking forward to that also!

Btw, that batch that *I* got excited about wasn't until may of 2015. That same recipe I will be kegging a batch of tomorrow. It is an 8% 2xIPA. The sampler I had was incredible! Our 3xIPA, 12% "R U Ready?!?", will be released on 2/3. Looking forward to that also!

Last edited:

Using RO water as your starting point is the easiest, most consistent way (in my opinion). I have water with bicarbonate in the 290 range - so, even higher than yours. The alkalinity makes light beers almost impossible (or much more labor intensive) to brew for sure. However, that said, Dark beers like porters and stouts, etc. can push pH down with acidic roast malts. I find 60-80% high bicarbonate tap water and 20-40% RO water allows me to hit a higher pH (5.5-5.7 range) and that makes for a much better dark beer. So, blending the two waters can also be a great tool. I use B'run water also for making my profiles.I’m starting to wonder why I don’t just use RO water on everything and add salts to make the profile I want. Seems like the easiest way to get exactly the water profile you want, no? I mean my water could change from the time I sent the report off to Ward Labs. It seems logical to just use RO water and this way I know almost exactly where I’m starting and then add the minerals using Brunwater. If this is the case do you just enter 0 for all of the minerals and calculate accordingly?

** RO water is not "0" - although, it is very low. B'run water has a dilution tap that you can select RO water for dilution and percent - that will fill in the average numbers of RO water for you.

Btw, that batch that *I* got excited about wasn't until may of 2015. That same recipe I will be kegging a batch of tomorrow. It is an 8% 2xIPA. The sampler I had was incredible! Our 3xIPA, 12% "R U Ready?!?", will be released on 2/3. Looking forward to that also!

Have you ever had post fermentation diacetyl? How do you deal with all those hops, removing them I mean from the finished product?

Since I started attempting NEIPAs been fighting this. Think the solution is introducing hops during fermentation but always looking for advice..

Manfish

Well-Known Member

Have you ever had post fermentation diacetyl? How do you deal with all those hops, removing them I mean from the finished product?

No, I have never had any post fermentation diacetyl issues.

As for how I deal with the hops, using conicals makes things much easier, just drop it out the bottom. Depending on the beer, meaning how much DHs goes into that beer, we might bag them as well. If not, its just toss them in and when it comes time, roll the conical from the fermentation room across into the cooler and let it sit until its clear and time to keg and put on the gas.

Thanks and good luck on your endeavor. If I'm ever in Washington, I'll have to stop by for a pint or 2..

My first three batches I brewed with my LHBS owner and he made the recipes and basically held my hand through the whole process. That first beer, an imperial red (8%) was hopped up, I think it had 8 oz of the C's in five gallons. But it was clear with bubbles and tasted like beer. I was happy. After three or four brews on my own, I believe I brewed my first really good beer. It was a Scottish 80, super malty with just enough hops to balance. I remember the feeling when the keg spit at me (dang). The next thing for me to work on is my water chem. It seems so confusing. What makes for a good dark beer or a good light beer? I need an idiots guide to brewing water. Right

How about fermentation temp control? This is much more important than temp you pitch at. Also, have you looked at your water chemistry? Lack of body, lack of head retention, and just tasting off makes me think you might have issues with your water profile.

I would agree that fermentation temp control is more important than pitch temp, but I wouldn't necessarily agree that pitch temp isn't important.

Within reason, of course. If you're trying to ferment at 65 and you pitch at 71 while it's cooling, it's not an issue. I would think that if you pitch at 85 and it takes 18-24 hours to cool down to your 65, though, you might experience some off flavors due to the high pitch temp and the high temps during the yeast reproductive phase.

Agree with you on water though, PARTICULARLY the point braufessor made about chlorine. If you have chlorine/chloramine in your water and you're not addressing it, it's just a no-no. But even beyond that I always had some troubles with really pale beers until I went to RO+minerals. Once I started controlling water, my pale beers improved FAR more than I would have thought possible given that I'd been brewing 9 years by that point.

- Joined

- Aug 8, 2017

- Messages

- 1,509

- Reaction score

- 1,783

I think for starters using distilled/RO water makes more sense. How about using distilled water? I have never seen RO water around me. Would distilled work just the same?

brandonlovesbeer

BrandonLovesBeer

I brewed quite a few decent beers right out of the gate. But I was lucky because my local water was EXCELLENT.

Then I moved to a different city only a few miles away but on a different water system. Then I learned what brewing difficulties actually were.

I’ve brewed 3 times at my new place and still haven’t gotten even a decent tasting beer. They have been less than sub par at best. It’s pretty frustrating.

My next beer will be with RO water. Hopefully that will do it.

Then I moved to a different city only a few miles away but on a different water system. Then I learned what brewing difficulties actually were.

I’ve brewed 3 times at my new place and still haven’t gotten even a decent tasting beer. They have been less than sub par at best. It’s pretty frustrating.

My next beer will be with RO water. Hopefully that will do it.

I think for starters using distilled/RO water makes more sense. How about using distilled water? I have never seen RO water around me. Would distilled work just the same?

Yes, distilled will work the same as RO. With either one, the key is that you need to add back in the salts/minerals that you want for the right water profile. Distilled will have zero dissolved minerals. RO will have almost zero dissolved minerals. So functionally they're basically the same.

I'm not an expert on starters, but I think you can use distilled. Since you don't have a mash, you don't need to worry about the mash mineral content. The DME will already contain everything you need. I'd consider adding a little yeast nutrient, though.

bigplunkett

Well-Known Member

First batch if recipes are an issue the database has a ton of great one if theres alot of repies chances are its good.

mrbeachroach

Well-Known Member

My first three batches I brewed with my LHBS owner and he made the recipes and basically held my hand through the whole process. That first beer, an imperial red (8%) was hopped up, I think it had 8 oz of the C's in five gallons. But it was clear with bubbles and tasted like beer. I was happy. After three or four brews on my own, I believe I brewed my first really good beer. It was a Scottish 80, super malty with just enough hops to balance. I remember the feeling when the keg spit at me (dang). The next thing for me to work on is my water chem. It seems so confusing. What makes for a good dark beer or a good light beer? I need an idiots guide to brewing water. Right

Maybe I am naïve however, every time I have used spring water it comes out perfectly. And I don't pay attention to the numbers.

I have made outstanding Russian Imperial Stout with 10.5 abv, ipa at 6abv

And light pale ale at 4.5ABV

All with the same water and have not had any issues.

- Joined

- Aug 8, 2017

- Messages

- 1,509

- Reaction score

- 1,783

I made a BB red Ale extract using Spring water and beer had a tang aftertaste. This was actually my first beer to ever brew. It was only months afterwards I learned adding spring water to extracts is not recommend led due to the minerals already in the extract.

I just pulled a sample off my first two using my new BB system and really surprised how clear this Pale Ale turned out.

View attachment 554866

I just dry hopped this Rosemary Pale using 3/4 oz Columbus, Citra, Nelson Sauvin, .5 fresh Rosemary. Going to be a fancy beer, can’t believe how clear and haven’t cold crashed yet. Beer on the right is a Old Highland Scotch Ale, hopefully it will darken during cold crash!

I just pulled a sample off my first two using my new BB system and really surprised how clear this Pale Ale turned out.

View attachment 554866

I just dry hopped this Rosemary Pale using 3/4 oz Columbus, Citra, Nelson Sauvin, .5 fresh Rosemary. Going to be a fancy beer, can’t believe how clear and haven’t cold crashed yet. Beer on the right is a Old Highland Scotch Ale, hopefully it will darken during cold crash!

Last edited:

I jumped all over the place. I have brewed 43 times since I started a year and a half ago. First 3 were extract, then a few partials and all grain with in 2 months. Built or bought 2nd hand all my equipment. I developed a method depending on batch size. I do 1.25 gallon, 3 gallon and 5 gallon. My goal was to read everything I could on brewing while trying to find what doesn't work and make all the mistakes I could. I got to know the brewers at my local brewery's and asked if I could join them ever so often. Most importantly I recorded everything and I mean everything! Develop a system in a journal that works for you and keep notes! I made some bad beers and some good ones but it wasn't until after a good year that I really felt like I had control of the brewing process. I finally got a brew that my girlfriend excepted as her favorite beer. Now she won't quite drinking it. If you aren't recording your brew days are then luck is the only thing that will get you a good beer. Oh yeah never take a short cut on cleaning your equipment. Cheers!

Well I just started brewing in October, and so far I've made a real beer, and I've made a good beer, but I still haven't made a real good beer.

kristiismean

Well-Known Member

- Joined

- Feb 25, 2015

- Messages

- 873

- Reaction score

- 202

First really good beer, probably 4 batches. But, that is nothing, the best beer I have made was my own recipe, probably 35 batches in. I made a stout that was really go as well about 20 batches in, but I am not a fan of stouts, but it was good.

Now let's talk about all the mediocre beers I have made... while learning. I am the one willing to experiment to learn how things go together. I can generally get beers to taste like I want them to..

but still chasing the balanced 10+ pale ale.....

Now let's talk about all the mediocre beers I have made... while learning. I am the one willing to experiment to learn how things go together. I can generally get beers to taste like I want them to..

but still chasing the balanced 10+ pale ale.....

My first batch was my best so far. It was a moderately complex Saison that just turned out well. I hit all my numbers and used a complicated step mashing schedule, but somehow my wonky recipe actually tasted really good. Fermented high with 3711+3724 and it dried out real nice. The three guys who work at the LHBS really liked it despite the fact that none of them are Saison fans, and they had no criticism other than it being a touch dark for the style. My wife loved it too and wants another batch so I'm stepping up a starter from dregs as we speak. Beginners luck I guess.

My next batch was a Hefeweizen where I mashed high and over-estimated my efficiency so I missed my numbers, then femented it at 62 ala Jamil, and it ended up thin, boring, and without a hint of banana.

Third was a Kölsch that I mashed a bit too high as well, I exceeded my target OG but it fermented well in the low-60's and actually turned out pretty good, just a bit too heavy bodied for the style.

Fourth was an attempt to clone Hacker-Pschorr Sternweiss, and full-flavored amber hefeweizen, fermented higher and pitched some yeast harvested from my first hefe. It had a strange peppery phenolic but the guys at my LHBS thought it turned out better than the first hefe and the Kölsch. Next time I will underpitch and ferment warmer yet.

I've since brewed and bottled a dubbel and a tripel, so far they taste great I just can't wait till they finish carbing.

Sunday I brewed another hefeweizen, this time with bavarian wheat yeast as it should supply more esters than the 3068 and I have it fermenting in the high-70's for maximum ester production.

So far each batch has been totally drinkable and better than store-bought beer, and anyway I'm learning a lot and tweaking my process, so pretty soon I think I'll be making great beers.

My next batch was a Hefeweizen where I mashed high and over-estimated my efficiency so I missed my numbers, then femented it at 62 ala Jamil, and it ended up thin, boring, and without a hint of banana.

Third was a Kölsch that I mashed a bit too high as well, I exceeded my target OG but it fermented well in the low-60's and actually turned out pretty good, just a bit too heavy bodied for the style.

Fourth was an attempt to clone Hacker-Pschorr Sternweiss, and full-flavored amber hefeweizen, fermented higher and pitched some yeast harvested from my first hefe. It had a strange peppery phenolic but the guys at my LHBS thought it turned out better than the first hefe and the Kölsch. Next time I will underpitch and ferment warmer yet.

I've since brewed and bottled a dubbel and a tripel, so far they taste great I just can't wait till they finish carbing.

Sunday I brewed another hefeweizen, this time with bavarian wheat yeast as it should supply more esters than the 3068 and I have it fermenting in the high-70's for maximum ester production.

So far each batch has been totally drinkable and better than store-bought beer, and anyway I'm learning a lot and tweaking my process, so pretty soon I think I'll be making great beers.

NealGamby

Member

- Joined

- Dec 20, 2017

- Messages

- 6

- Reaction score

- 0

OP,

I’ve educated myself on the basics. Meaning I’ve lurked on this forum for a long time, there’s a lot of good information and it’s FREE. Then watched a lot of Homebrew videos on YouTube. I think it’s important to familiarize yourself with the terms and process of brewing beforehand. Still...experience is the best teacher.

My first batch was an American Pale Ale, turned out terrific. Second batch was a blueberry wheat ale, and that turned out just OK because it was too sweet. The biggest key for me in the beginning was to sanitize everything and have good clean water. It’s half the battle. The other half, is getting the formula down.

Did you cold crash the Hefe? I got 5 gallons in a new SS conical fermenter bucket right now. Thinking about throwing that in the kegerator to cold crash.

I’ve educated myself on the basics. Meaning I’ve lurked on this forum for a long time, there’s a lot of good information and it’s FREE. Then watched a lot of Homebrew videos on YouTube. I think it’s important to familiarize yourself with the terms and process of brewing beforehand. Still...experience is the best teacher.

My first batch was an American Pale Ale, turned out terrific. Second batch was a blueberry wheat ale, and that turned out just OK because it was too sweet. The biggest key for me in the beginning was to sanitize everything and have good clean water. It’s half the battle. The other half, is getting the formula down.

My first batch was my best so far. It was a moderately complex Saison that just turned out well. I hit all my numbers and used a complicated step mashing schedule, but somehow my wonky recipe actually tasted really good. Fermented high with 3711+3724 and it dried out real nice. The three guys who work at the LHBS really liked it despite the fact that none of them are Saison fans, and they had no criticism other than it being a touch dark for the style. My wife loved it too and wants another batch so I'm stepping up a starter from dregs as we speak. Beginners luck I guess.

My next batch was a Hefeweizen where I mashed high and over-estimated my efficiency so I missed my numbers, then femented it at 62 ala Jamil, and it ended up thin, boring, and without a hint of banana.

Third was a Kölsch that I mashed a bit too high as well, I exceeded my target OG but it fermented well in the low-60's and actually turned out pretty good, just a bit too heavy bodied for the style.

Fourth was an attempt to clone Hacker-Pschorr Sternweiss, and full-flavored amber hefeweizen, fermented higher and pitched some yeast harvested from my first hefe. It had a strange peppery phenolic but the guys at my LHBS thought it turned out better than the first hefe and the Kölsch. Next time I will underpitch and ferment warmer yet.

I've since brewed and bottled a dubbel and a tripel, so far they taste great I just can't wait till they finish carbing.

Sunday I brewed another hefeweizen, this time with bavarian wheat yeast as it should supply more esters than the 3068 and I have it fermenting in the high-70's for maximum ester production.

So far each batch has been totally drinkable and better than store-bought beer, and anyway I'm learning a lot and tweaking my process, so pretty soon I think I'll be making great beers.

Did you cold crash the Hefe? I got 5 gallons in a new SS conical fermenter bucket right now. Thinking about throwing that in the kegerator to cold crash.

I personally wouldn't cold crash a hefe, you risk dropping too much of the yeast and wheat protein that are important for the proper flavor and body, and also might reduce the head. I used whirlfloc on my first hefe, I dunno what I was thinking but that probably also contributed to the thin body and loss of flavor. Never gonna make that mistake again.Did you cold crash the Hefe? I got 5 gallons in a new SS conical fermenter bucket right now. Thinking about throwing that in the kegerator to cold crash.

From what I've read, to get that authentic Bavarian flavor (I sampled a lot of really fresh hefeweizens during my 5 years living in southern Germany), you should under-pitch, under-aerate, and ferment warm. Stressed yeast produce the estery flavors of a Bavarian hefeweizen, and fresh from the tap examples have a distinct creamy aroma and flavor that gets lost on the way to US retailers. I'm speaking specifically of König Ludwig, but Huber-Weisses, Sanwald, and Maisel's Weisse have it too.

I used only RO water for the first 2+ years brewing, but then decided to see what my tap water did with campden (or whatever they are called) tablets. I haven't yet tried one of the beers made with only de chlorinated tap water, but one thing I do know is my water has a lot of sodium (84) and the pale that is in the fermenter may not be drinkable. I'm going back to RO and will start using some additions.Maybe I am naïve however, every time I have used spring water it comes out perfectly. And I don't pay attention to the numbers.

I have made outstanding Russian Imperial Stout with 10.5 abv, ipa at 6abv

And light pale ale at 4.5ABV

All with the same water and have not had any issues.

NealGamby

Member

- Joined

- Dec 20, 2017

- Messages

- 6

- Reaction score

- 0

I personally wouldn't cold crash a hefe, you risk dropping too much of the yeast and wheat protein that are important for the proper flavor and body, and also might reduce the head. I used whirlfloc on my first hefe, I dunno what I was thinking but that probably also contributed to the thin body and loss of flavor. Never gonna make that mistake again.

From what I've read, to get that authentic Bavarian flavor (I sampled a lot of really fresh hefeweizens during my 5 years living in southern Germany), you should under-pitch, under-aerate, and ferment warm. Stressed yeast produce the estery flavors of a Bavarian hefeweizen, and fresh from the tap examples have a distinct creamy aroma and flavor that gets lost on the way to US retailers. I'm speaking specifically of König Ludwig, but Huber-Weisses, Sanwald, and Maisel's Weisse have it too.

That’s about right. Cold crashing is purely for clarifying reasons, at least from what I read. I also have whirfloc in a small baggy and now I’m hesitating on using it. Did it impact your hefe that much??

I don't know to what degree it was responsible for the lack of body, but I think whirlfloc binds proteins causing them to coagulate and fall out of solution. It was a very good tasting batch and has become crystal clear in the bottle, it just lacked the sturdy "liquid bread" qualities that I love. It was more like a kristallweizen than a hefeweizen.That’s about right. Cold crashing is purely for clarifying reasons, at least from what I read. I also have whirfloc in a small baggy and now I’m hesitating on using it. Did it impact your hefe that much??

If your sodium is high in your tap water..... is it water that came from your water softener? In general, water from a water softener does not make good brewing water because the softening process replaces some minerals with other minerals (like sodium). If I am using my tap water (usually for dark beers that benefit from the high alkalinity) I use one of the faucets on the outside of my house for brewing water (because it is not hooked to the softener).I used only RO water for the first 2+ years brewing, but then decided to see what my tap water did with campden (or whatever they are called) tablets. I haven't yet tried one of the beers made with only de chlorinated tap water, but one thing I do know is my water has a lot of sodium (84) and the pale that is in the fermenter may not be drinkable. I'm going back to RO and will start using some additions.

No I don't have a softener attached.If your sodium is high in your tap water..... is it water that came from your water softener? In general, water from a water softener does not make good brewing water because the softening process replaces some minerals with other minerals (like sodium). If I am using my tap water (usually for dark beers that benefit from the high alkalinity) I use one of the faucets on the outside of my house for brewing water (because it is not hooked to the softener).

- Joined

- Aug 8, 2017

- Messages

- 1,509

- Reaction score

- 1,783

Progress! I believe I’m making progress my friends! Yesterday I kegged what I believe to be my best beer to date! A Rosemary Pale Ale that is quite tasty!

This afternoon I scaled a Nut Brown recipe I brewed on my old 5 gallons system. I scaled this recipe to 8 gallons and came within 4 points of hitting my OG. Not too mention hitting my boil volume using 17lbs of grain! This was also my first attempt to use distilled water and build my water profile using brewing salts! For the first time I hit my mash ph 5.3!

OG should have been 1.054 and I hit 1.050.

This afternoon I scaled a Nut Brown recipe I brewed on my old 5 gallons system. I scaled this recipe to 8 gallons and came within 4 points of hitting my OG. Not too mention hitting my boil volume using 17lbs of grain! This was also my first attempt to use distilled water and build my water profile using brewing salts! For the first time I hit my mash ph 5.3!

OG should have been 1.054 and I hit 1.050.

Last edited:

- Joined

- Dec 16, 2015

- Messages

- 935

- Reaction score

- 355

It was my 3rd batch that I finally felt was good enough to share. It was Braufessor's NEIPA back when that thread was 10 pages, not 140+. My first brew was a northern brewer irish red extract kit that I rushed through because I thought I knew more than I did. I had helped my friend brew before, and I had a kegorator that would work as a fermentation chamber with good control. I could do no wrong. It was bad. Came out murky brown and had strong onion tastes that got worse with time. Poured most of that batch.

Second batch I went all grain and was a recipe I wrote myself based on Allagash's House Beer. Got it totally wrong, came out very red. Wasn't overly bad, just not great. I drank that whole batch.

Third batch was the NEIPA. I started with distilled water and calculated additions. Paid a lot of attention to all the steps. Only thing I messed up was the first hop addition when I used twice as much as I should have. That beer was good, if not very bitter. That's the one I shared with friends.

I've made beers that I thought were amazing, like my Porter. And some that just suck, like my latest stout. I have much to still learn.

Second batch I went all grain and was a recipe I wrote myself based on Allagash's House Beer. Got it totally wrong, came out very red. Wasn't overly bad, just not great. I drank that whole batch.

Third batch was the NEIPA. I started with distilled water and calculated additions. Paid a lot of attention to all the steps. Only thing I messed up was the first hop addition when I used twice as much as I should have. That beer was good, if not very bitter. That's the one I shared with friends.

I've made beers that I thought were amazing, like my Porter. And some that just suck, like my latest stout. I have much to still learn.

I've drank all 6 of my batches so far; it's not that they weren't good enough to share, I just love my beer and it's all mine mine mine.

However, I do have 2 batches that will be ready to share on superbowl sunday, a dubbel and a tripel. If I get any stupid f@cking questions about my process or my beer, I'm taking my beer and going home to drink it all in my underpants.

Friends are overrated.

However, I do have 2 batches that will be ready to share on superbowl sunday, a dubbel and a tripel. If I get any stupid f@cking questions about my process or my beer, I'm taking my beer and going home to drink it all in my underpants.

Friends are overrated.

I don't know how many brews in I was or exactly when any more, but when I started using good yeast strains and proper for the style made a huge difference on my quality. Also making sure that the yeast was happy in its environment. I don't use fermenting chambers or worry about controlling temps, but I brew beers and use yeasts that work with my current working conditions. If it is winter, I lager. Spring and fall I make ale. Summer I don't brew.

I totally agree with your point about brewing with the season but use the hot summer weather to your advantage, brew hefeweizen and saison!....If it is winter, I lager. Spring and fall I make ale. Summer I don't brew.

Similar threads

- Replies

- 16

- Views

- 805

- Replies

- 53

- Views

- 2K

- Replies

- 6

- Views

- 382