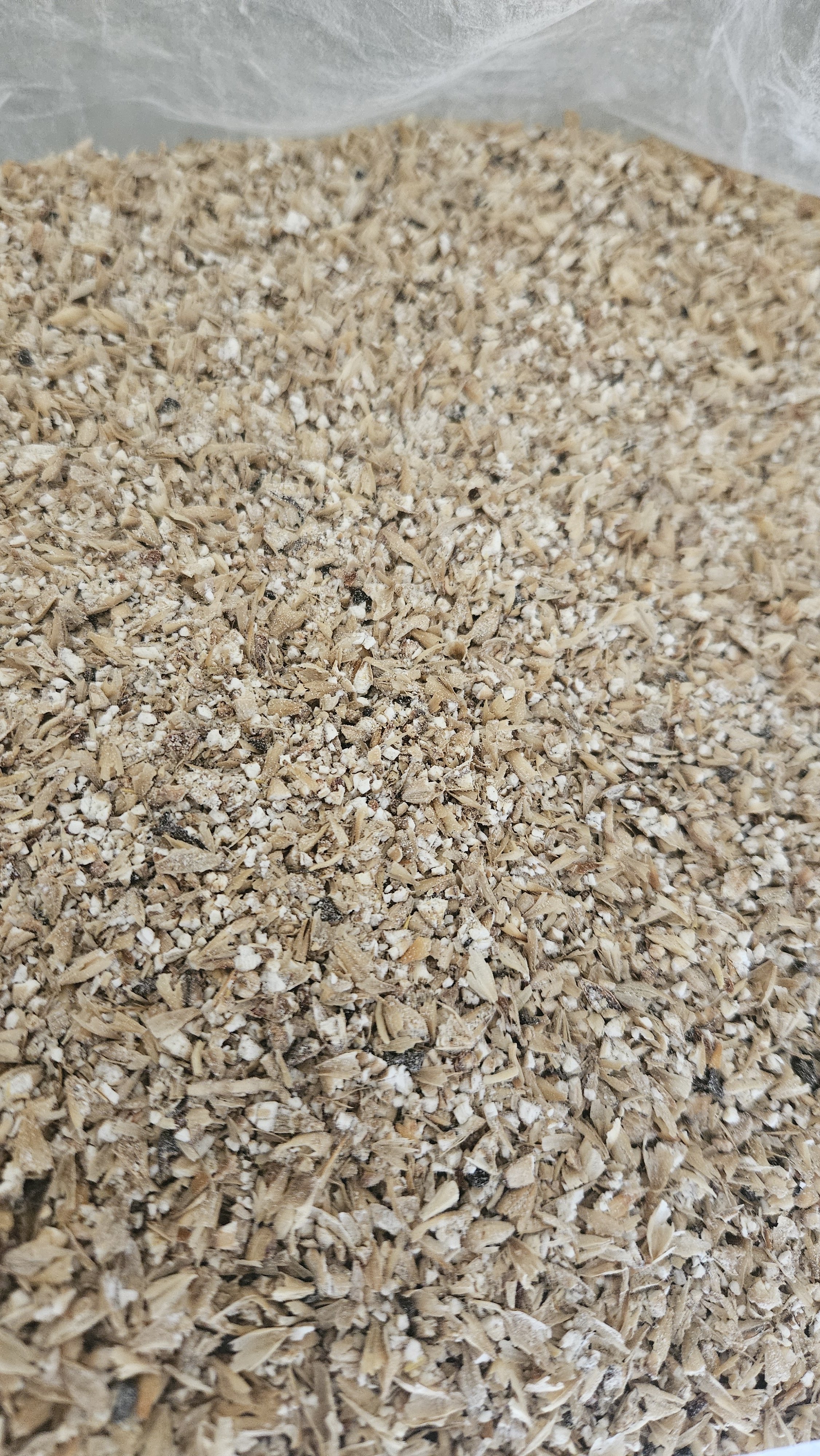

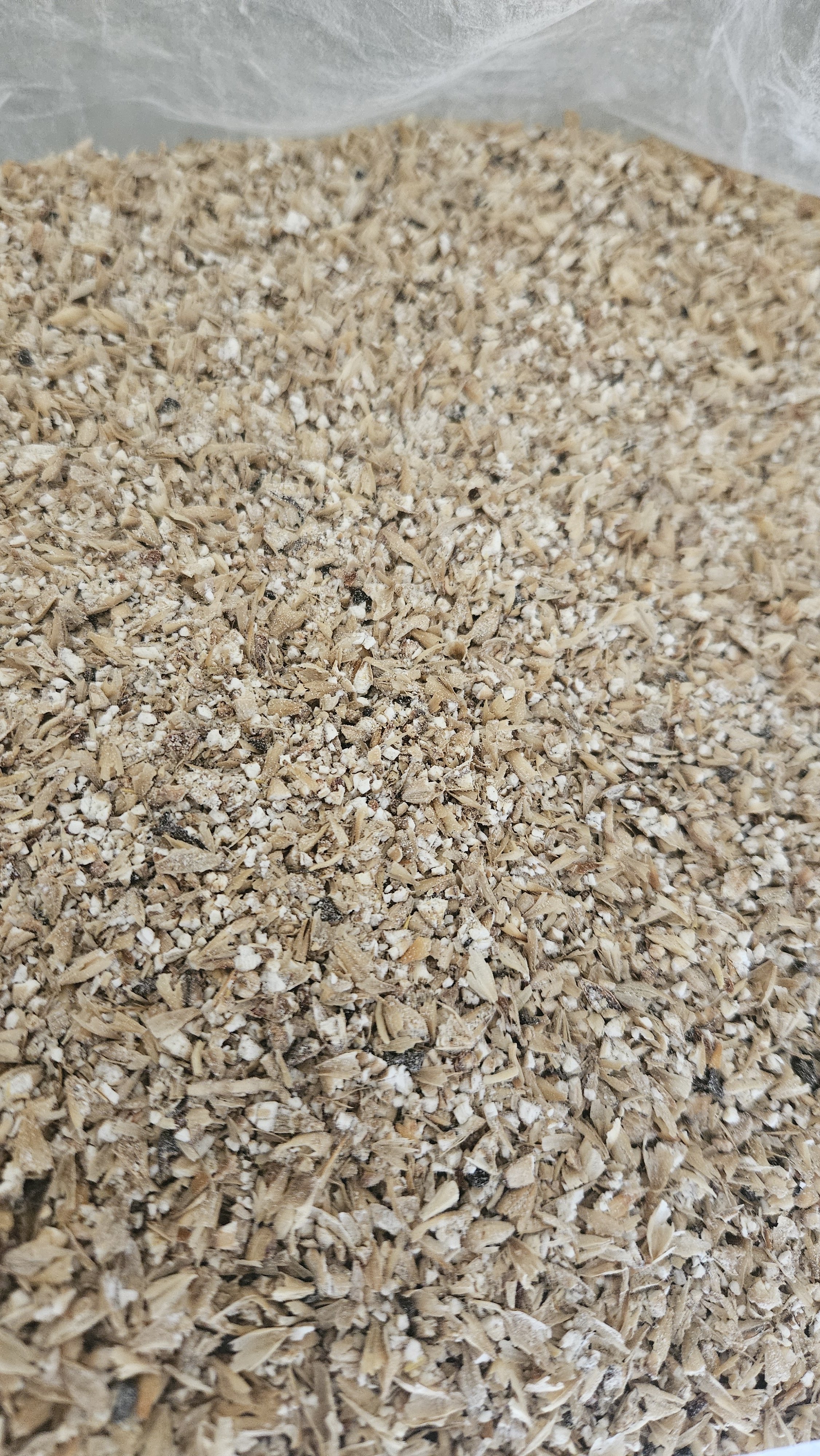

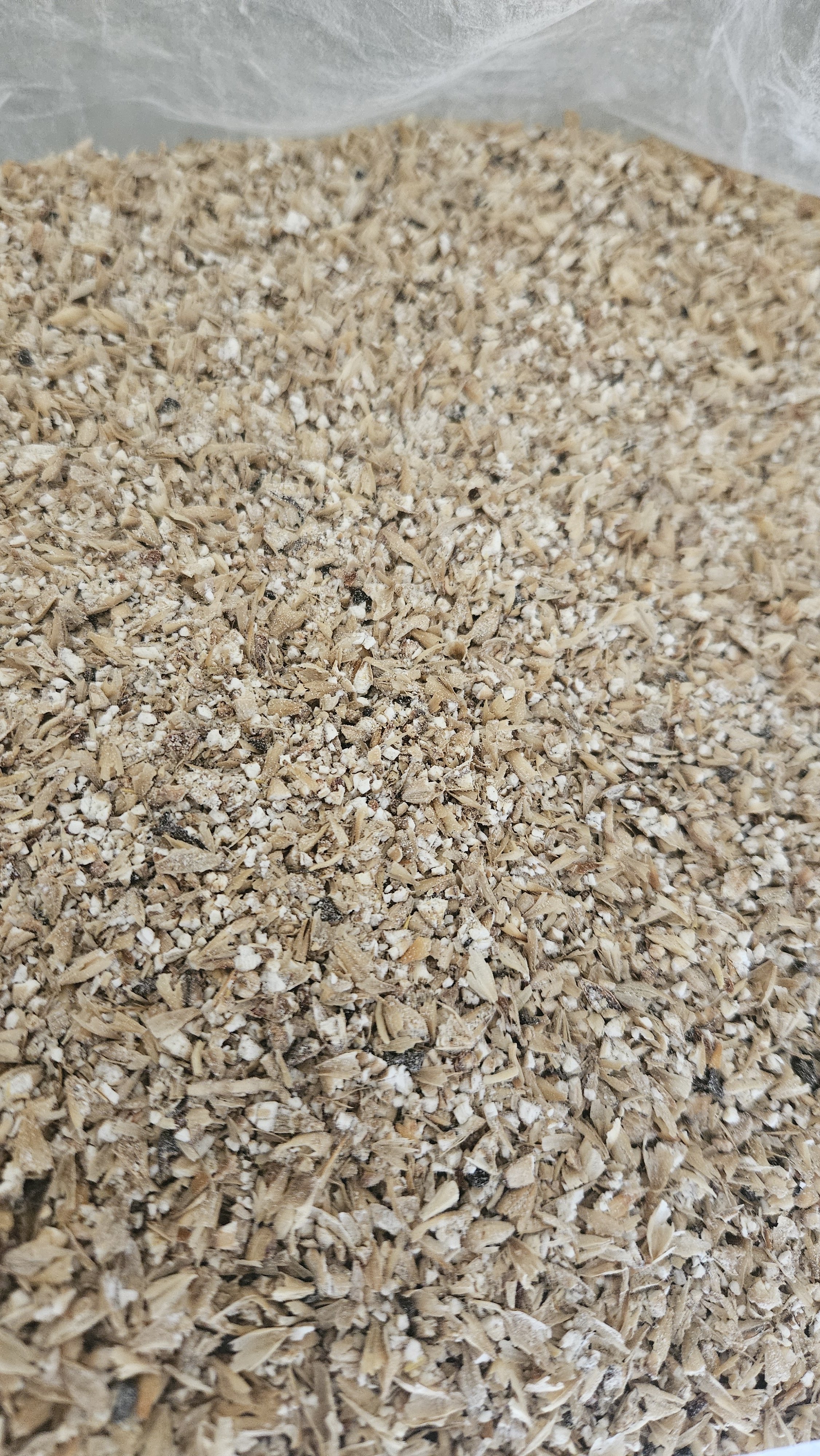

Is this too fine? Still trying to get the right spot on the Spike mill. I have to use my brew bag to keep clumps of grain out of the wort.

I feel like I've read a similar post somewhereThanks. Was a good brew day all around until the garden hose shot off from the chiller and started whiplashing around the garage...fun times

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Spike mill at .040 and the last bit I went@hilljack13 What did you have that set to?

I must be doing something different because, according to the GF app calculation, my efficiency was 73% brewhouse and 77 mash. I am at least seeing some consistency on those numbers..040 is my standard crush w/ 69% efficency last brew. Some may want higher %'s but I'm not commercial, I am in the ballpark on gravity, and the beer tastes good so I don't sweat it.

I crush 0.030 for a batch sparge. No stuck sparges and like 73% eff.Is this too fine? Still trying to get the right spot on the Spike mill. I have to use my brew bag to keep clumps of grain out of the wort.

View attachment 860610

As @CascadesBrewer said, it depends on your mash/lauter system. With a BIAB system you can crush quite a bit tighter, as the bag is your (very fine) filter. Adding a dunk sparge should add a few extra points to your wort.Spike mill at .040 and the last bit I went

.045

Similar to mine, but I do adjust the gap for the malt size, typically once per milling session:I crush 0.030 for a batch sparge.

Using a converted cooler mash tun, I enjoy 85-87% mash efficiency at 1.5 qt/lb followed by 2 equal volume batch sparges, fully drained before, and thoroughly stirred after each water addition.No stuck sparges and like 73% eff.

Interesting. I noticed in the first picture that many of the grain husks looked more torn than just crushed. I was not sure if this was a good or bad thing, but it sounds like it is a goal.

- Offset Driven Rollers: The rollers are turned at different speeds (1.3:1) as this helps to shear the grain husk rather than crushing it and producing excess flour and dust.

With "the good stuff" do you mean the runnings from the fly sparge?If you turn your malt into flour, you'll get greater conversion but you might not be able to retrieve the good stuff from the mash; a major problem for the lauter.

The most dramatic way I've improved my brewhouse efficiency is to collect and sparge SLOWLY.

I don't think shredding husks is a good thing. Shear as the grain gets crushed, is what tends to shred the husks. I have a geared roller mill w/1:1 gear ratio, so there is almost no shear going thru the rollers. I can crush at a roller spacing of 0.022" and get almost all intact husks. Not sure why Spike would design a mill that purposely shears the kernels and shreds husks.Interesting. I noticed in the first picture that many of the grain husks looked more torn than just crushed. I was not sure if this was a good or bad thing, but it sounds like it is a goal.

Proper fly sparging hinges on a slow drain, as it does on a slow matching supply on top, to keep the water column intact.The most dramatic way I've improved my brewhouse efficiency is to collect and sparge SLOWLY.

When I started all grain brewing, I already owned a Corona mill, so I used it. I adjusted it down to where I saw no more whole grains; then a little more. At first, I was concerned that I might end up with a stuck sparge. A couple years in, I got one with an oatmeal stout; I blame the oatmeal, even though I didn’t run it through the mill. It was not too difficult to fix, just stuck my long spoon in and worked it around a little.There are a couple of high end mills with different drive rpms between rollers - and I also was/am skeptical that it made sense. Grain passing through a pair of rollers running at the same RPM doesn't experience much "shear", just compression - the "crush" - which seems to me to be the optimal approach. It's similar to the difference between roller mills and disc mills like the classic "corona" mills - the latter of which tend to make chaff bits out of husks...

Cheers!

My guess is that Spike is marketing the BIAB homebrewer as to why they went with shredding the husks.I don't think shredding husks is a good thing. Shear as the grain gets crushed, is what tends to shred the husks. I have a geared roller mill w/1:1 gear ratio, so there is almost no shear going thru the rollers. I can crush at a roller spacing of 0.022" and get almost all intact husks. Not sure why Spike would design a mill that purposely shears the kernels and shreds husks.

If anyone has any links to published work on shredded vs. intact husks affect on lautering, I would be very interested.

Brew on

My mill motor seems to be torque limited in some way. I got a cleaning brush caught in the rollers, and it did stop before any damage was done to the rollers or other mill parts. The brush wasn't so fortunate.My guess is that Spike is marketing the BIAB homebrewer as to why they went with shredding the husks.

I still use my 3-roller (non-geared) mill for my fly sparging method of brewing. I am leary about geared roller mills for fear of a non crushable object (small pebble) getting through and causing havoc. Hopfully your mill is equipped with a shear pin or other method to avoid damage to the mill if a non crushable object gets through.

I guess another plus for lining the tun with a Wilser bag, aye? I never thought one of those hopper bolts would vibrate loose. That hopper will get tack welds and I’ll ditch those bolts. Guess Loctite should have been in the assembly schematic.My monster mm3 tried to eat one of the bolts that rattled loose. No problem, mashed it thinking the shrapnel would sink.